Unidirectional permeable concrete structure and preparation method thereof

A technology of concrete structure and permeable concrete, which is applied in the field of building materials, can solve the problems of loss of permeable structure and impermeability of rainwater, etc., and achieve the effect of improving the efficiency of permeable operation, increasing urban groundwater resources, and reducing engineering maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

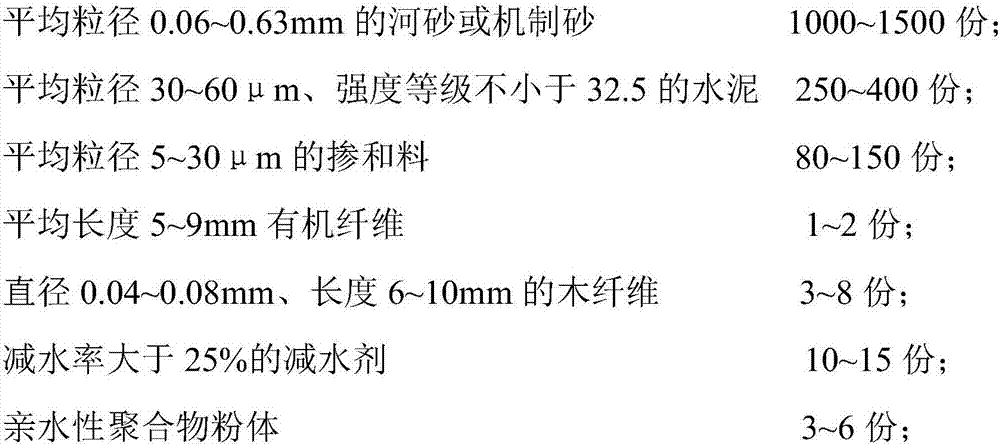

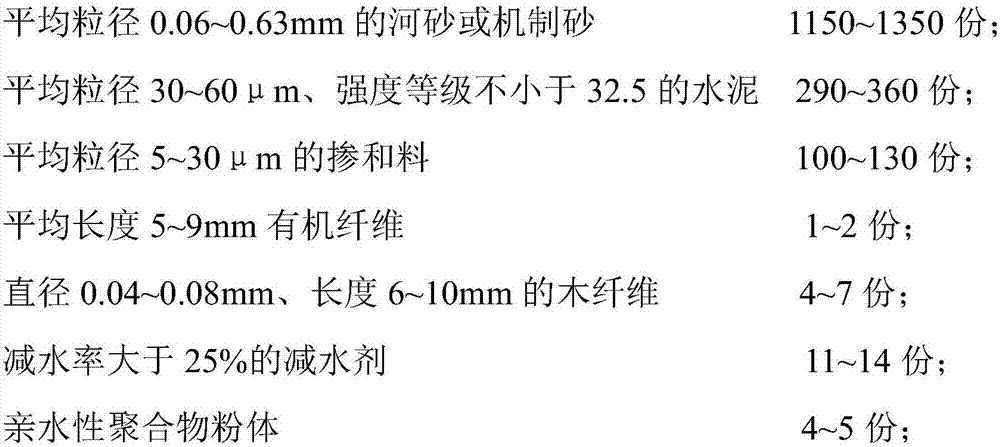

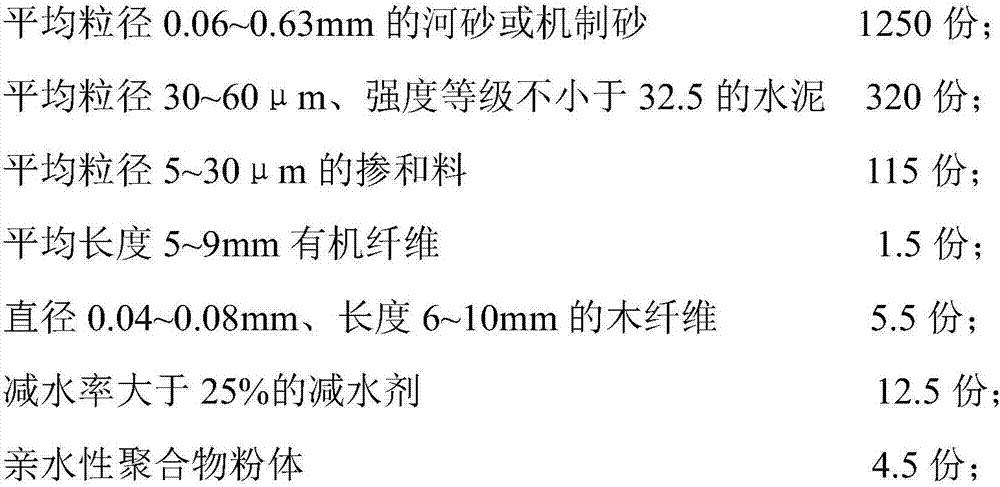

Examples

preparation example Construction

[0069] And, the embodiment of the present invention also provides a method for preparing the above-mentioned one-way permeable concrete structure, including the following steps:

[0070] Step 1. Weigh each raw material component according to the mixing ratio of the water-permeable filter layer, pre-stir all the aggregates, fibers and 40% by weight of water for 60-90 seconds, then add all the cement, stir for 60-90 seconds, and then Add all the water reducing agent and the remaining 60% by weight of water, fully stir for 90-120 seconds, finally add the hydrophilic polymer, and stir for 30-60 seconds to obtain the concrete mixture of the permeable filter layer;

[0071] Step 2. Calculate the raw material components according to the mixing ratio of the one-way water-permeable layer. First, pre-stir all the aggregate and 40% by weight of water for 60-90 seconds, then add all the cement, stir for 60-90 seconds, and then add The whole water reducer and the remaining 60% by weight of...

Embodiment 1

[0080] A one-way permeable concrete structure, which is composed of a permeable base layer, a one-way permeable layer and a permeable filter layer sequentially combined from bottom to top, wherein the permeable filter layer is made of the first permeable concrete doped with a hydrophilic polymer Made, the aggregate particle size of the first permeable concrete is ≤0.63mm, and the compressive strength of the permeable filter layer is >30 MPa, the permeable hole diameter is 1.2mm / s; The one-way permeable layer is made of the second permeable concrete doped with hydrophobic polymer, and the aggregate particle size of the second permeable concrete is ≤1.25mm, and the compressive strength of the one-way permeable layer is >30 MPa , the aperture of the permeable hole 5mm / s; the permeable base is made of the third permeable concrete, the aggregate particle size of the third permeable concrete is 5-15mm, and the permeable base is resistant to Compressive strength > 40 MPa, permeable h...

Embodiment 2

[0095] A one-way permeable concrete structure, which is composed of a permeable base layer, a one-way permeable layer and a permeable filter layer sequentially combined from bottom to top, wherein the permeable filter layer is made of the first permeable concrete doped with a hydrophilic polymer Made, the aggregate particle size of the first permeable concrete is ≤0.63mm, and the compressive strength of the permeable filter layer is >30 MPa, the permeable hole diameter is 1.2mm / s; The one-way permeable layer is made of the second permeable concrete doped with hydrophobic polymer, and the aggregate particle size of the second permeable concrete is ≤1.25mm, and the compressive strength of the one-way permeable layer is >30 MPa , the aperture of the permeable hole 5mm / s; the permeable base is made of the third permeable concrete, the aggregate particle size of the third permeable concrete is 5-15mm, and the permeable base is resistant to Compressive strength > 40 MPa, permeable h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com