Janus fabric membrane based on polylactic acid and preparation method and application of Janus fabric membrane

A polylactic acid, fabric film technology, applied in textiles and papermaking, one-component synthetic polymer rayon, one-component polyester rayon, etc., to achieve the effect of firm bonding, thermal comfort and good breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

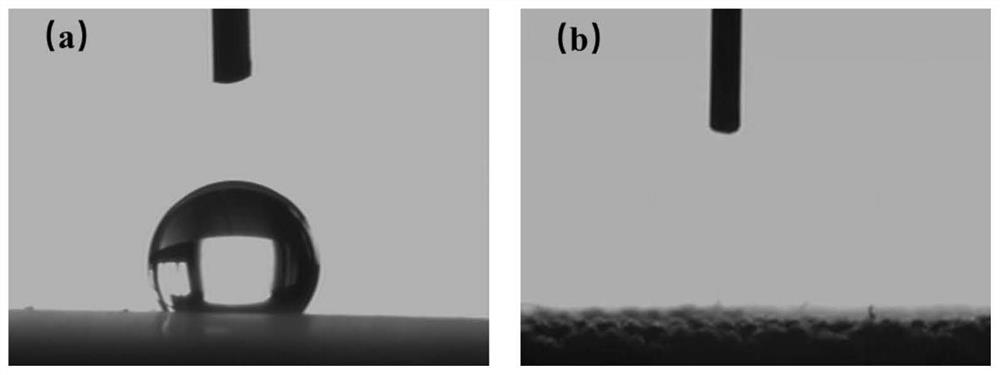

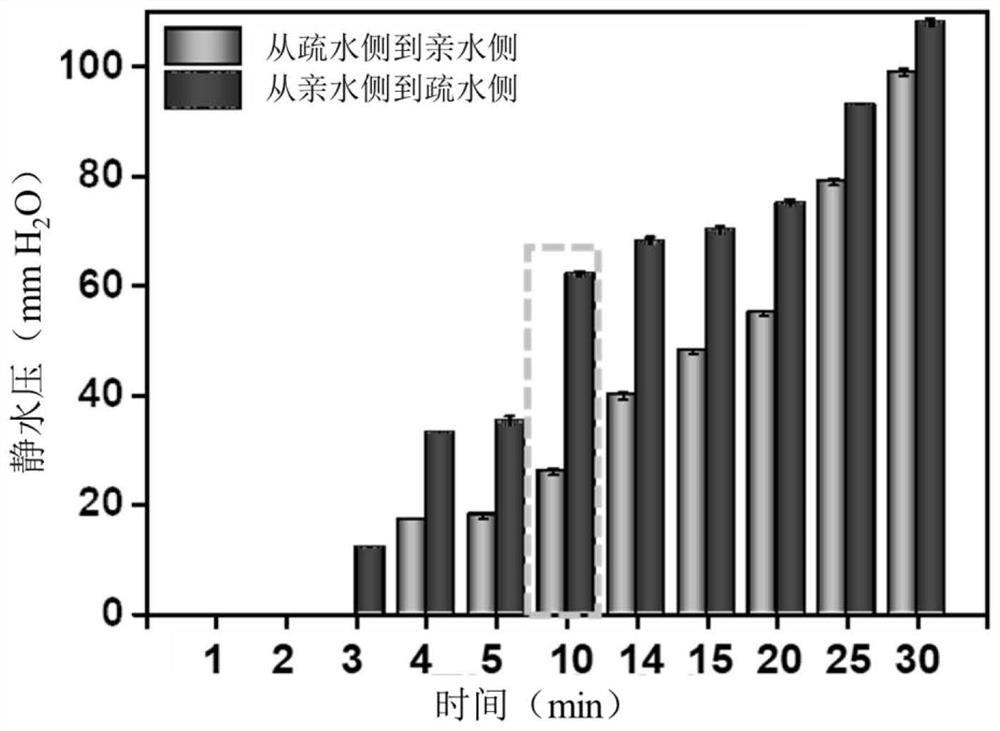

[0038] According to the present invention, a kind of preparation method of the Janus fabric film based on polylactic acid is provided, the method may further comprise the steps:

[0039] Step 1, preparing a modified polylactic acid fabric layer.

[0040] According to the present invention, step 1, preparation of modified polylactic acid fabric layer comprises:

[0041] Step 1.1, pretreating the polylactic acid fabric to obtain the pretreated polylactic acid fabric;

[0042] Step 1.2, preparing inorganic particles on the pretreated polylactic acid fabric.

[0043] The inventors found that ultraviolet protection is more important to people's healthy life, non-toxic, tasteless nano-titanium dioxide particles have a good shielding effect on ultraviolet rays, nano-titanium dioxide particles can effectively absorb ultraviolet light to generate hole-electron pairs, and have a good effect on ultraviolet light. It has good scattering effect, will not decompose and change color under ...

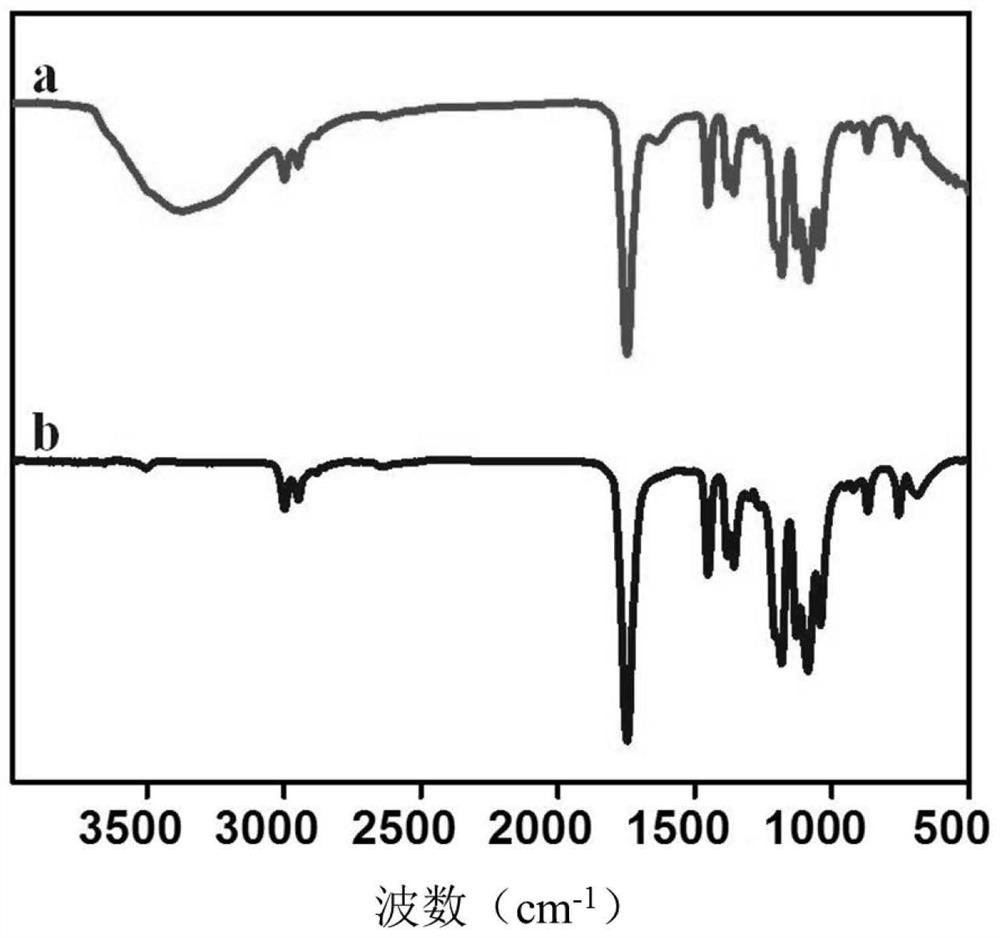

Embodiment 1

[0103] Cut the polylactic acid fabric into a size of 10cm×10cm, wash it several times with deionized water and 10g / L sodium hydroxide solution, and dry it to obtain a polylactic acid fabric treated with sodium hydroxide solution, which is called PLA (NaOH) fabric. spare;

[0104] Add water to Tris to form a Tris pH buffer solution with a concentration of 10 mM, add dopamine powder to the Tris pH buffer solution to form a dopamine-Tris buffer solution with a concentration of 0.5 g / L, and adjust its pH value to 8.5 with hydrochloric acid;

[0105] Immerse the PLA (NaOH) fabric in the dopamine-Tris buffer solution and stir for 24 hours, take it out, wash it with absolute ethanol, and dry it at 60°C for 2 hours to obtain a pretreated polylactic acid fabric, which is designated as PLA-PDA fabric;

[0106] Add 1mL deionized water to 500mL absolute ethanol to obtain mixed solution I;

[0107] Add 20 mL of n-butyl titanate dropwise to the mixed solution I, and the mixed solution II i...

Embodiment 2

[0112] Repeat the process of Example 1, the difference is that the spinning time is 4min, and other processes are the same as in Example 1 to obtain the Janus fabric membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com