Asymmetric wettability composite membrane and preparation method thereof

A composite membrane and wettability technology, applied in the field of asymmetric composite membranes and their preparation, can solve the problem that the unidirectional water conductivity still needs to be improved, and achieve the effects of excellent moisture permeability, excellent thermal conductivity, and ensuring thermal comfort in wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

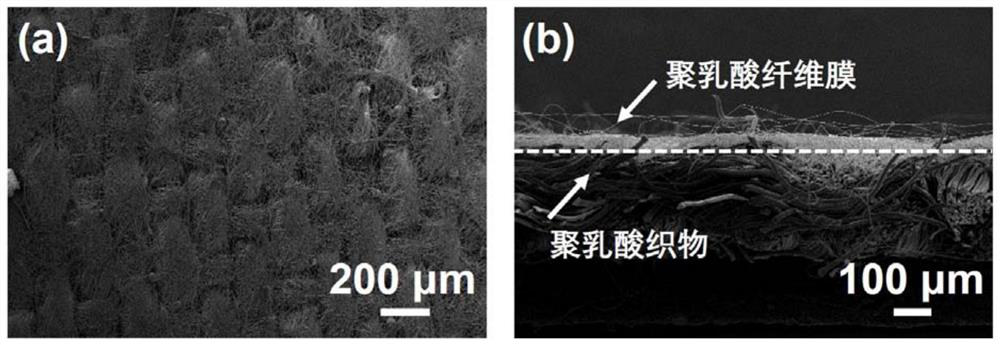

[0059] The preparation method of the asymmetric wettable composite membrane is described in detail below.

[0060] Step 1, preparing a hydrophilic polymer base layer.

[0061] In step 1, the hydrophilic polymer fabric is alkali-treated to obtain a hydrophilic polymer base layer.

[0062] In step 1, the hydrophilic polymer fabric is selected from polysulfone fabric, polyamide fabric, polyamic acid fabric, polyimide fabric, polyurethane fabric, polyacrylic acid fabric, polylactic acid fabric, polyethylene oxide fabric And any one or more in the polyvinylpyrrolidone fabric, preferably polylactic acid fabric, such as the polylactic acid fabric produced by Puyang Yurun New Material Co., Ltd., wherein 50wt% polylactic acid, 18wt% acetic acid and 32wt% Tencel.

[0063] Among them, the choice of hydrophilic polymer fabric has a direct impact on the hydrophilicity of the asymmetric wettable composite membrane, and green and environmental protection are also considerations. Represente...

Embodiment 1

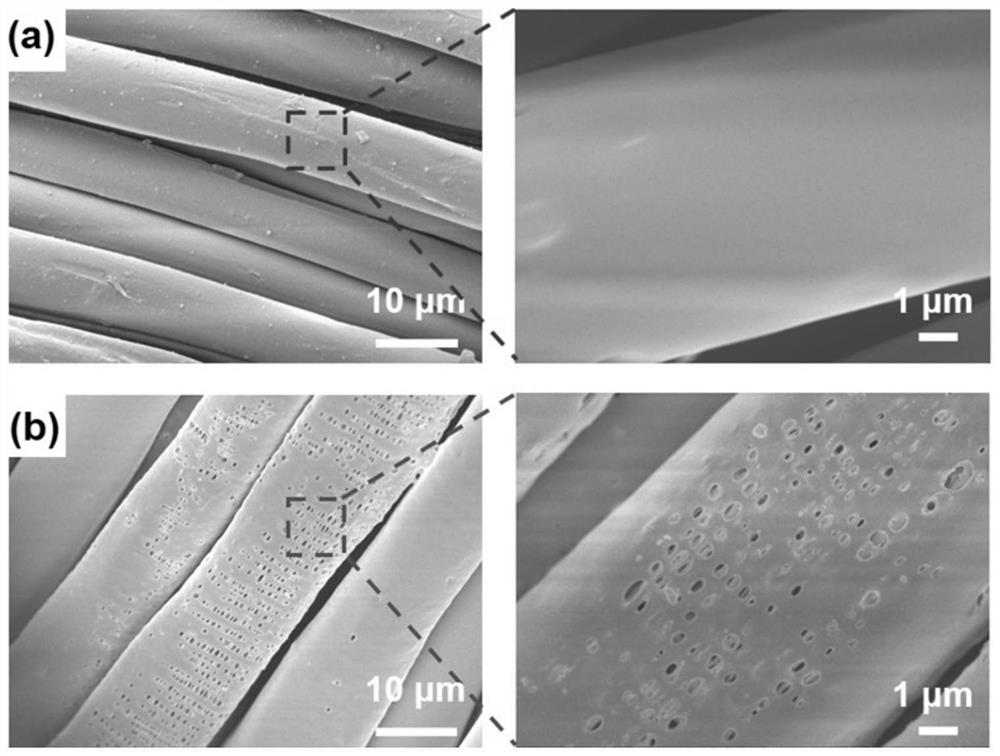

[0108] (1) Polylactic acid fabric (abbreviated as PLA fabric, composed of 50wt% polylactic acid, 18wt% acetic acid and 32wt% tencel, produced by Puyang Yurun New Material Co., Ltd.) was cut into a square of 8cm × 8cm, and its Soak in a NaOH solution with a concentration of 10g / L for 3h, and then place the PLA fabric in a ventilated place to dry for 24h to prepare a hydrophilic polymer base layer, namely NaOH@PLA fabric.

[0109] (2) Weigh 1.5g of polylactic acid (PLA) particles (produced by Zhejiang Hisun Biomaterials Co., Ltd.) into a 25mL conical flask, then add 12.285g of mixed solvent (N,N-dimethylformamide: tetrahydrofuran =7:3(w / w)), to obtain a mixed solution with a PLA particle concentration of 10wt%, the Erlenmeyer flask was well sealed, and placed on a magnetic stirrer with a temperature of 40°C and a rotating speed of 400rmp for 3h until the PLA particles Completely dissolved to obtain the PLA spinning solution precursor.

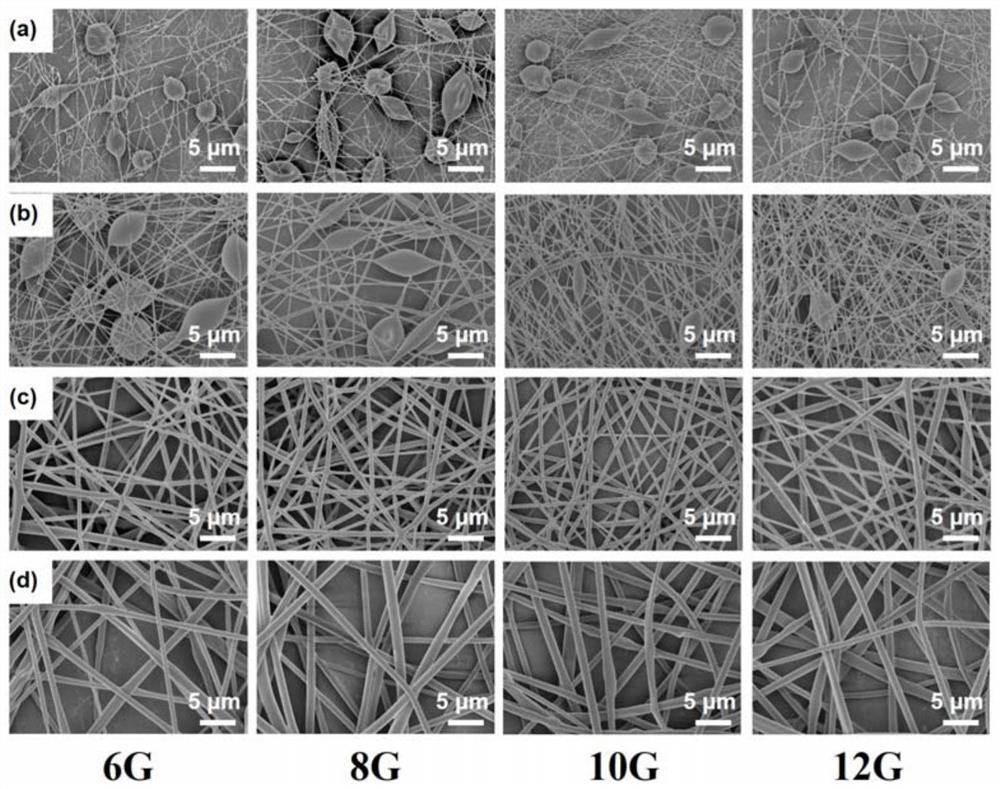

[0110] (3) Lay the NaOH@PLA fabric prepar...

Embodiment 2

[0113] The PLA-NaOH@PLA composite film was prepared in a similar manner to Example 1, with the difference that: a 6G spinneret was used, and the thickness of the PLA-NaOH@PLA composite film was measured to be 256.6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com