Preparation method of mold spore product

A technology for mold spores and spores, which is applied in the field of preparation of mold spore products, can solve the problems of easy reduction of vitality, inconvenient storage and transportation, time-consuming and laborious elution of spores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

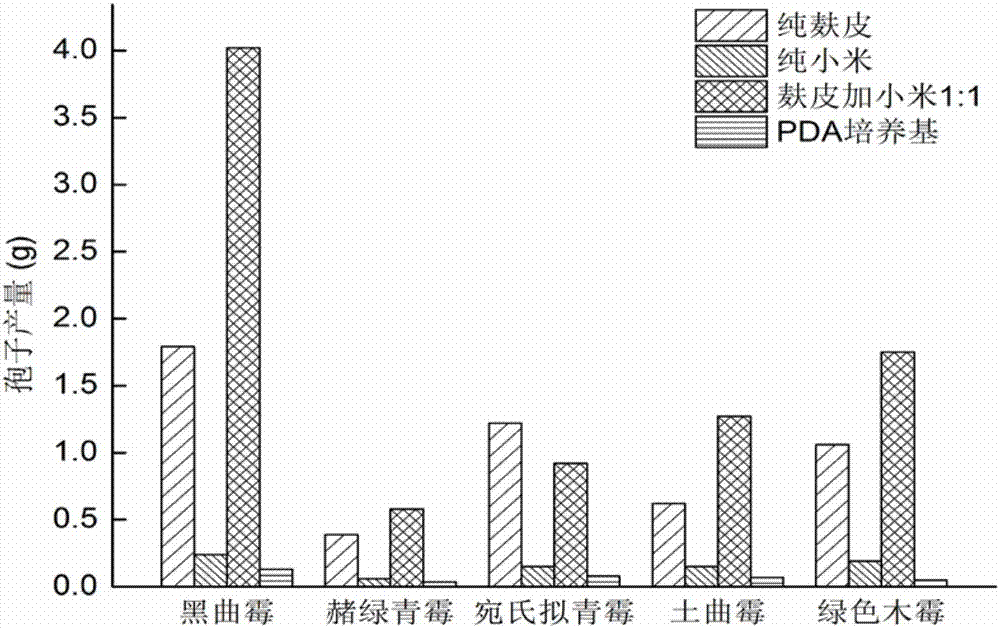

[0024] 1. Selection of training methods

[0025] Inoculate ten strains of Aspergillus niger, Aspergillus terreus, Aspergillus flavus, Aspergillus versicolor, Paecilomyces variegae, Cladophyllum brevis, Penicillium fungus, Penicillium ochrevi, Trichoderma globosa, Trichoderma viride, etc. Potato agar plate, potato slant, potato agar eggplant bottle, bran flat plate, bran flat triangular flask culture, culture at 28°C. Observe the growth and growth speed, compare the sporulation yield when the spores are mature, and the difficulty of elution and separation, so as to choose the best culture method.

[0026] The growth rate of the mold is shown in Table 1.

[0027] The growth situation of each strain in table 1 in different media

[0028]

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com