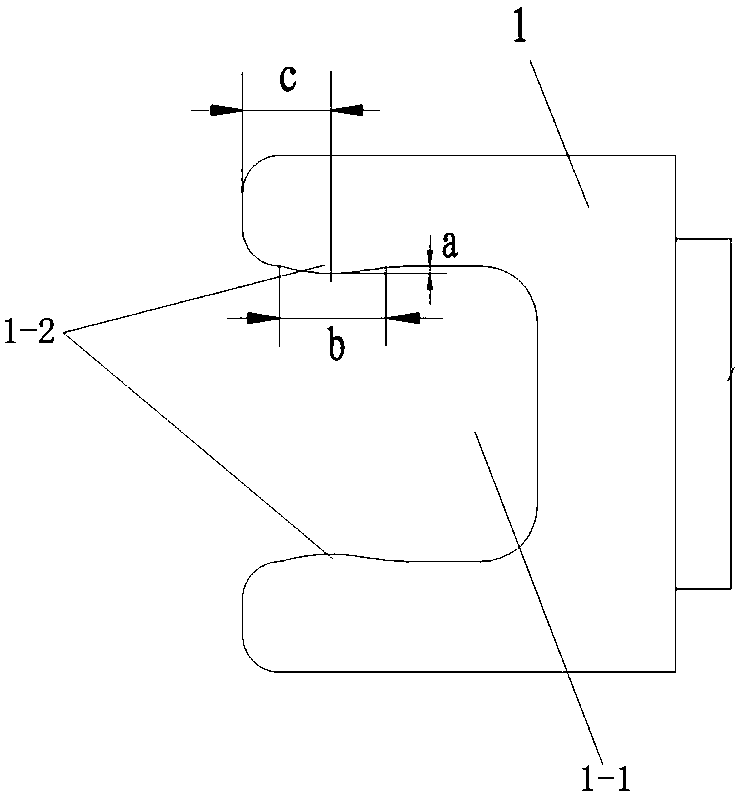

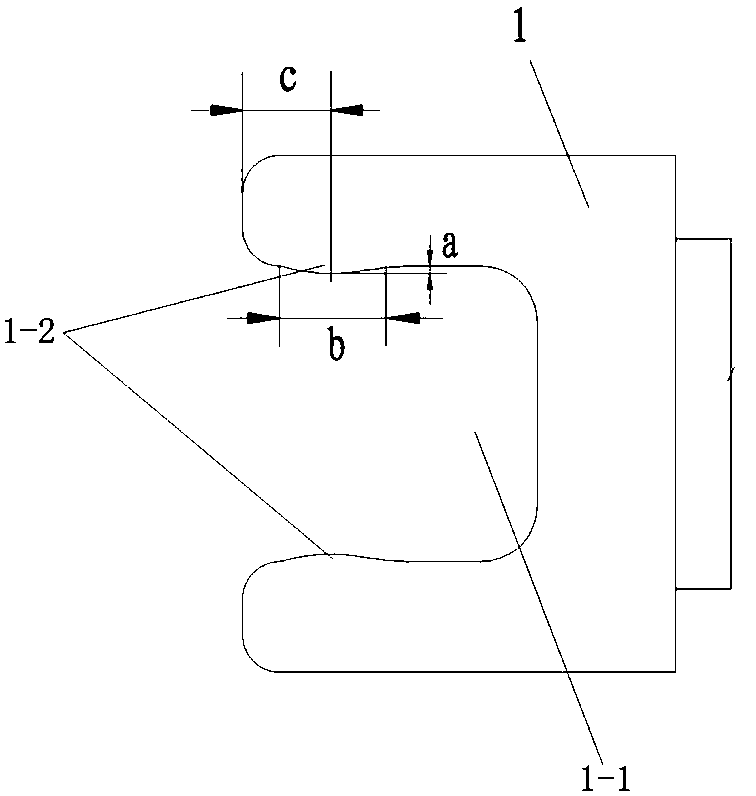

A powder metallurgy warp knitting machine needle bar retaining element and its preparation process

A technology of powder metallurgy and retaining components, which is applied in warp knitting, metal processing equipment, knitting, etc., can solve the problems of short life, poor fatigue resistance, high production cost, etc., achieve excellent toughness and strength, reduce pattern defects, The effect of high raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

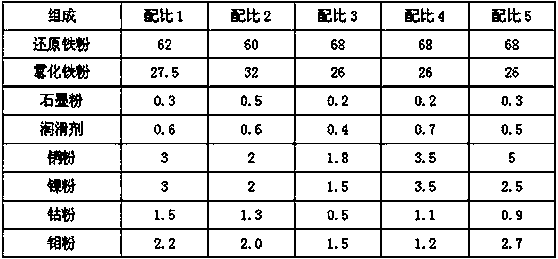

[0031]According to the ratio 1 in Table 1, the raw materials were weighed respectively, iron powder, copper powder, nickel powder, cobalt powder, molybdenum powder, graphite powder, and lubricant were added to the mixer and mixed for 50 minutes, and then left to stand for 48 hours after mixing, so that The components are sufficiently stable to prevent the segregation of alloy elements during the feeding process, and the mixed powder is obtained; the mixed powder is transported to the hopper of the press, and the mixed powder material is sent into the mold cavity through the automatic feeding mechanism of the press, and the feeding is controlled. The volume of the mixed powder in the mold cavity is 2.2 times the volume of the finished product, and it is pressed for 2 seconds under a pressure of 580 MPa to obtain a green compact;

[0032] Send the compact into the mesh belt sintering furnace, and pass in the protective gas. The protective gas consists of 70% nitrogen and 30% hydr...

Embodiment 2

[0037] According to the ratio 2 in Table 1, the raw materials were weighed respectively, and iron powder, copper powder, nickel powder, cobalt powder, molybdenum powder, graphite powder, and lubricant were added to the mixer and mixed for 60 minutes in turn, and then left to stand for 60 hours after mixing, so that The components are sufficiently stable to obtain mixed powder; the mixed powder is transported to the hopper of the press, and the mixed powder material is sent into the mold cavity through the automatic feeding mechanism of the press, and the volume of the mixed powder sent into the mold cavity is controlled to be the volume of the finished product 2.5 times of , press molding under 630MPa pressure for 3s to obtain a green compact;

[0038] Send the compact into the mesh belt sintering furnace, and pass in the protective gas. The protective gas consists of 70% nitrogen and 30% hydrogen, and the intake volume of nitrogen is 6m 3 / h, the inlet pressure is 0.12MPa, th...

Embodiment 3

[0042] According to the ratio 1 in Table 4, the raw materials were weighed respectively, iron powder, copper powder, nickel powder, cobalt powder, molybdenum powder, graphite powder, and lubricant were added to the mixer and mixed for 50 minutes, and then left to stand for 72 hours after mixing, so that The components are sufficiently stable to obtain mixed powder; the mixed powder is transported to the hopper of the press, and the mixed powder material is sent into the mold cavity through the automatic feeding mechanism of the press, and the volume of the mixed powder sent into the mold cavity is controlled to be the volume of the finished product 2.1 times of , press molding under 580MPa pressure for 2s to obtain compact;

[0043] Send the compact into the mesh belt sintering furnace, and pass in the protective gas. The protective gas consists of 70% nitrogen and 30% hydrogen, and the intake volume of nitrogen is 6m 3 / h, the inlet pressure is 0.12MPa, the oxygen content of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com