Test structure, test probe card, test system and test method

A test structure and test probe technology, which is applied in the field of semiconductors, can solve the problems of WAT test accuracy to be improved, and achieve the effects of reduced test cost, improved test accuracy, and improved test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

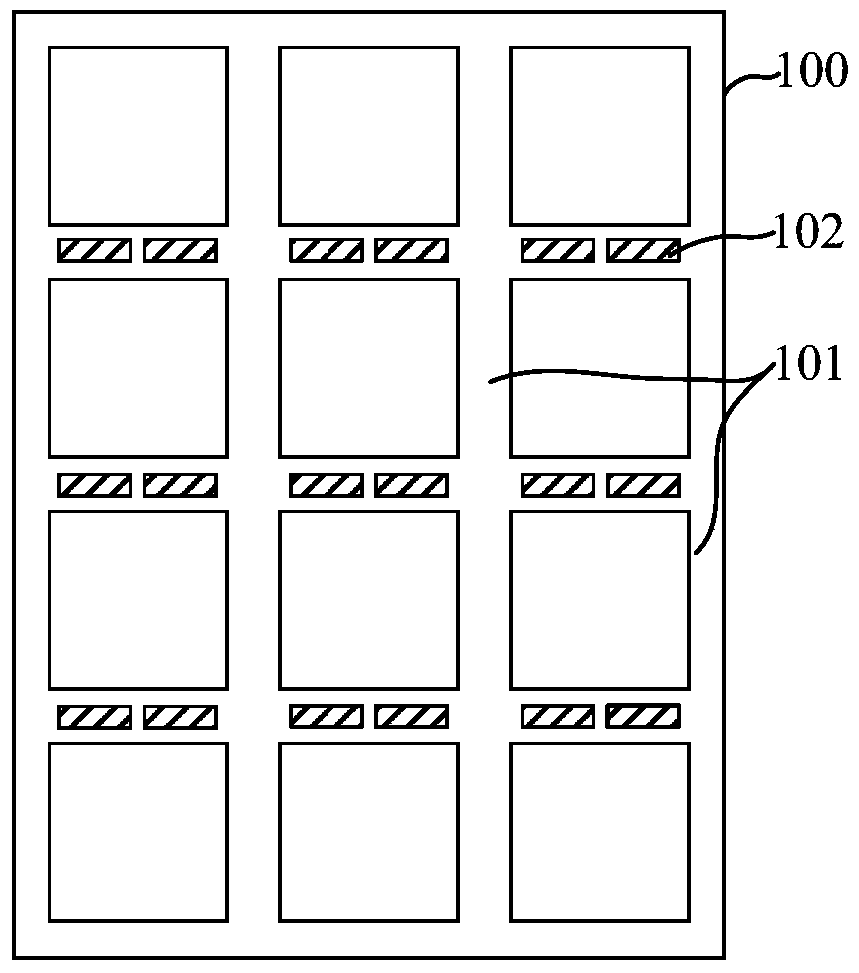

[0019] The test accuracy of the prior art is low, combined with reference figure 1 and figure 2 , shows a schematic diagram of an embodiment of the prior art testing method. Analyze the reasons for this:

[0020] Such as figure 1 As shown, several test structures 102 are located within the dicing line 101 of the wafer 100 . In the prior art, a probe card (not shown) is usually used for testing, and after the test of a test structure 102 is completed, the probe card is moved from the test structure 102 to the next structure to be tested 102 positions And continue to test until all test structures 102 are tested.

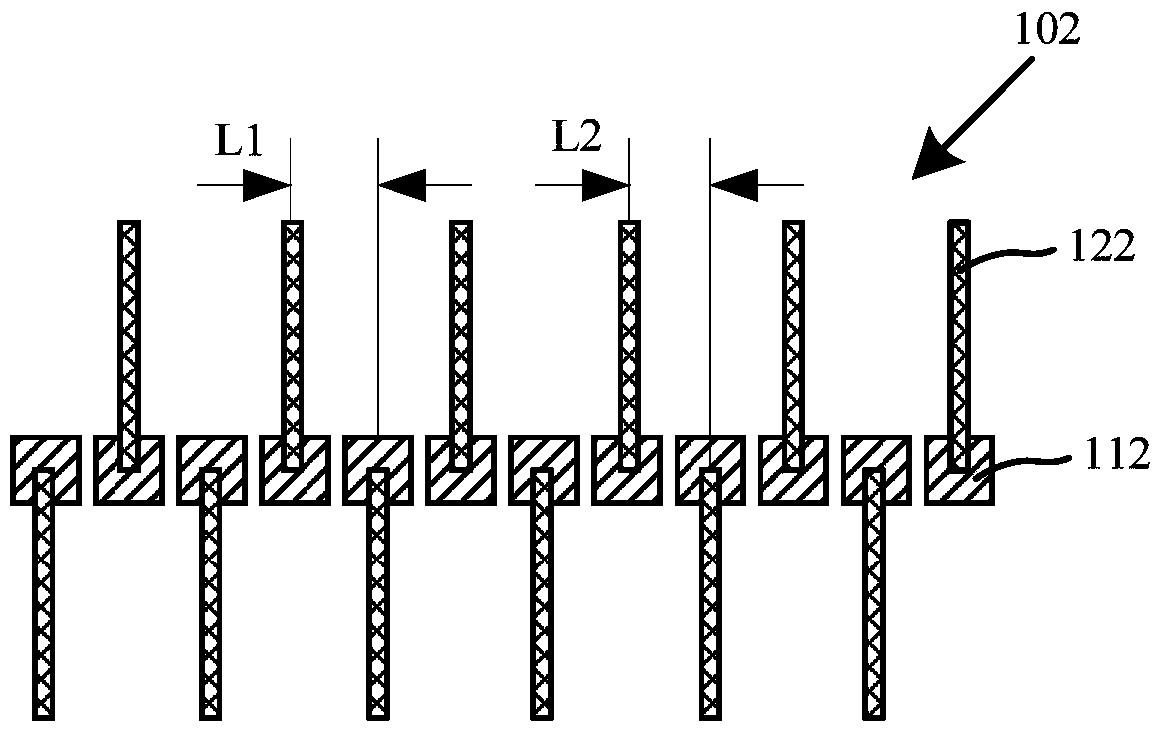

[0021] Specifically, as figure 2 As shown, the test structure 102 includes a plurality of test pads 112 , and the probe card includes a plurality of probes 122 . Wherein, the number of the test pads 112 is equal to the number of the probes 122 , and the probes 122 are in contact with the test pads 112 in a one-to-one correspondence. At present, the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com