Vacuum cleaner motor and vacuum cleaner

A vacuum cleaner, motor control technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as the inability to increase the speed, and achieve the effect of overcoming the inability to increase the speed, prolonging the service life, and operating reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

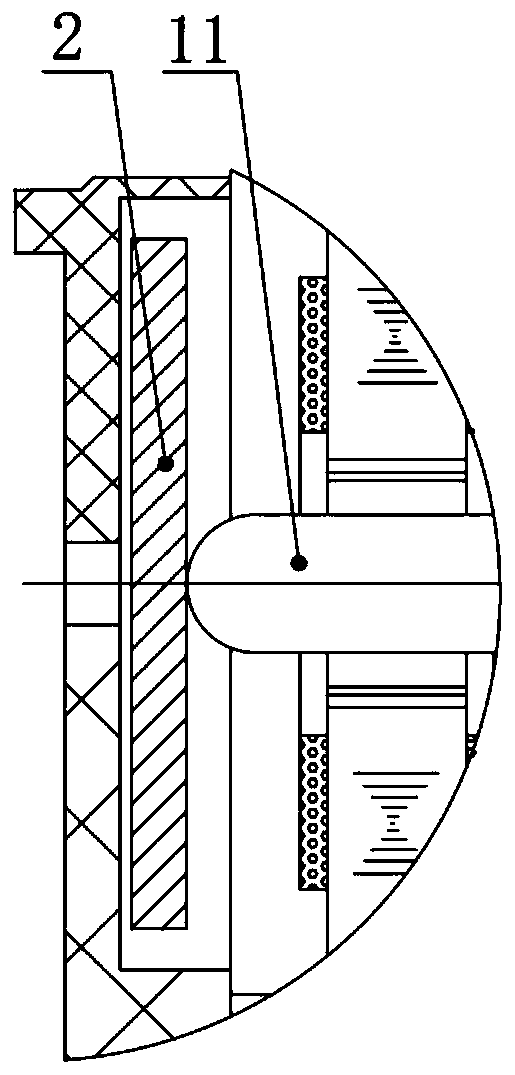

[0031] In other embodiments, the axial fixing plate 2 can be connected to the motor control board 1 and integrated with the motor control board 1 .

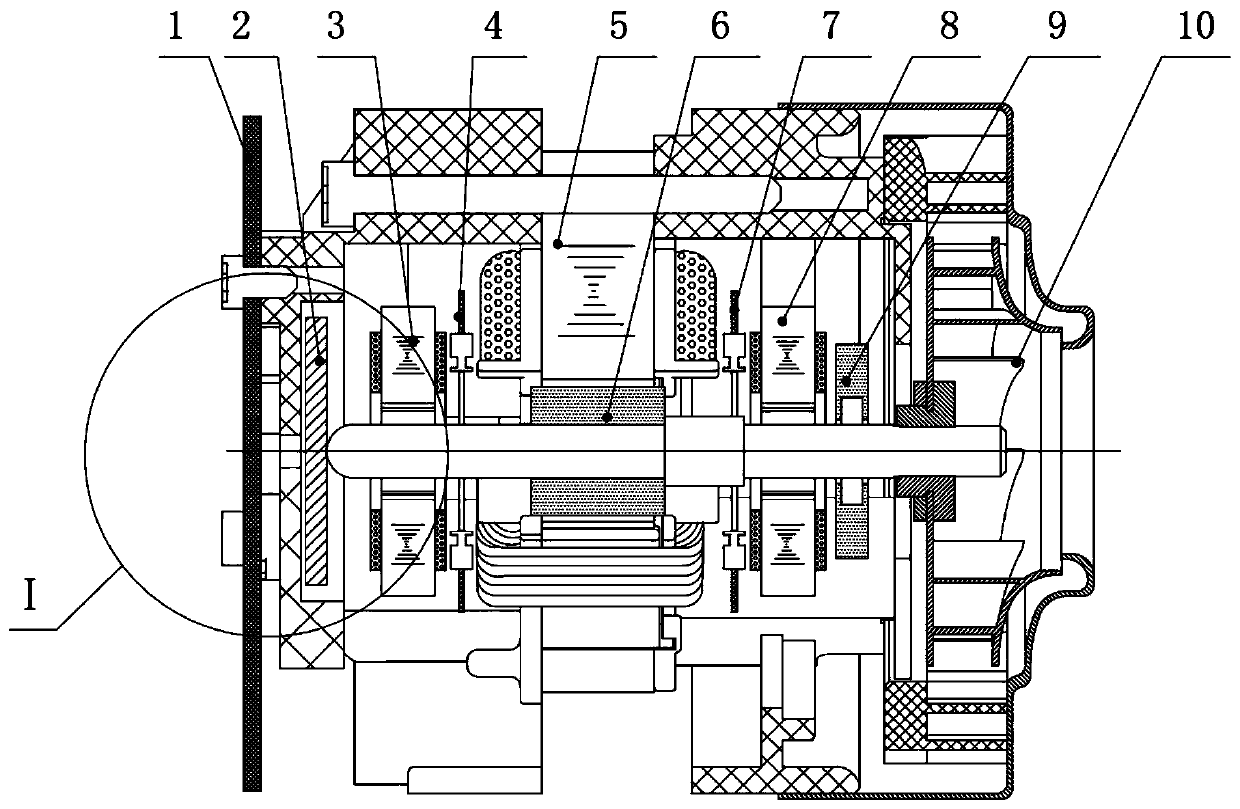

[0032] The magnetic suspension bearings of the vacuum cleaner motor are all controlled by the motor control board. When the motor starts, it first detects the position of the rotor shaft through the radial position sensor and the axial position sensor, and transmits the deviation signal of the rotating shaft to the motor control board. The controller, the controller performs a moderate calculation on the position deviation signals detected by the radial position sensor and the axial position sensor, and converts the calculated control signal into a control current after passing through the motor power amplifier, and the control current generates a magnetic force in the magnetic suspension bearing , so as to drive the rotor shaft to correct the position. Therefore, the rotor shaft can quickly return to the reference position. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com