Fattening method for drylot-feeding goats

A technology for goat and barn feeding, applied in the field of animal husbandry, can solve the problems of high feeding cost, increase in daily increment of goats, and long fattening time for sheep, and achieve the effects of reducing disease incidence, reducing feed waste and improving fattening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

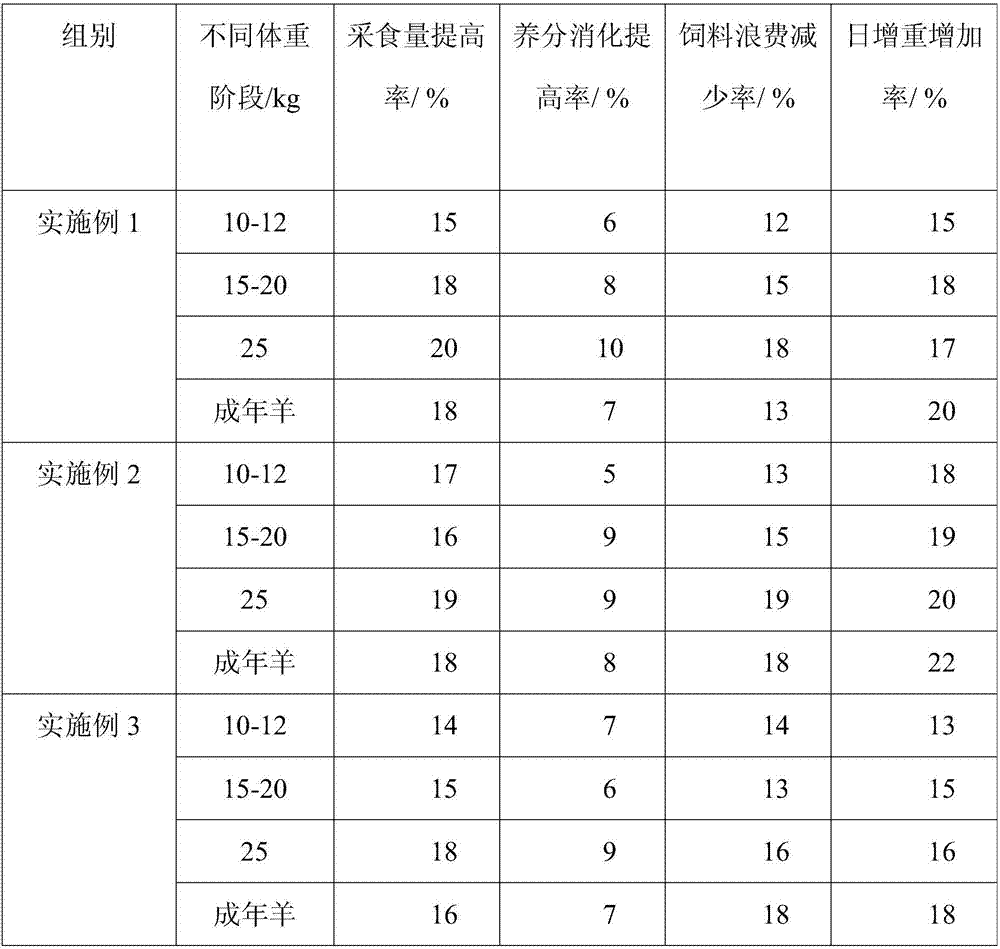

Examples

Embodiment 1

[0037] (1) Composition and ingredients of the total mixed ration:

[0038] In weight percentage, the fattening concentrate includes the following components: 45% corn, 14% wheat bran, 12% rapeseed meal, 5% rice bran, 20% silkworm excrement and 4% premix.

[0039] In percent by weight, the coarse material includes the following components: 75% of silage corn stalks, 10% of soybean stalks, and 15% of alfalfa grass.

[0040] (2) The preparation method of full mixed ration, its step is:

[0041] (1) Prepare various raw materials according to the formula of fattening concentrate;

[0042] (2) Determination of the moisture content of silage corn stalks in order to determine the formulation of the total mixed diet and moisture control;

[0043] (3) Knead soybean stalks and alfalfa grass to a grass section of 5-8 cm with a coarse material rubbing machine;

[0044] (4) According to the formula ratio, the prepared silage corn stalks, soybean straw sections, alfalfa grass sections, an...

Embodiment 2

[0054] In terms of weight percentage, the fattening concentrate includes the following components: 44% corn, 15% wheat bran, 12% rapeseed meal, 5% rice bran, 20% wine tank powder, and 4% premix.

[0055] In percent by weight, the coarse material includes the following components: 75% ryegrass, 10% soybean straw, and 15% alfalfa grass.

[0056] (2) The preparation method of the fully mixed diet of different concentrate and roughage ratios, the steps are:

[0057] (1) Prepare various raw materials according to the formula of fattening concentrate;

[0058] (2) Determining the moisture content of ryegrass in order to determine the formulation and moisture control of the total mixed diet;

[0059] (3) Knead the soybean stalks and alfalfa grass to a grass section of 5-8cm with a coarse material rubbing machine;

[0060] (4) According to the formula ratio, the prepared ryegrass, soybean straw section, alfalfa grass section, and concentrate are sequentially transported to the raw m...

Embodiment 3

[0070] In weight percentage, the fattening concentrate includes the following components: 50% corn, 16% wheat bran, 10% soybean meal, 15% rapeseed meal, 5% rice bran and 4% premix.

[0071] In weight percentage, the coarse material includes the following components: 55% of silage red sweet potato vines, 20% of mixed weeds, 10% of peanut vines, and 15% of alfalfa grass.

[0072] (2) The preparation method of the fully mixed diet of different concentrate and roughage ratios, the steps are:

[0073] (1) Prepare various raw materials according to the formula of fattening concentrate;

[0074] (2) Determination of the moisture content of silage red sweet potato vines and mixed weeds, so as to determine the formula and moisture control of the total mixed diet;

[0075] (3) Knead the peanut vine and alfalfa grass to a grass section of 5-8cm with a coarse material rubbing machine;

[0076] (4) According to the formula ratio, the prepared silage red sweet potato vine and mixed weeds,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com