A kind of preparation method of external plaster for expelling rheumatism

A technology for expelling wind-dampness and plastering, which is applied in the field of preparation of external plaster, and can solve the problems of unsatisfactory drug effect, poor pertinence, and difficult volatilization of active ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

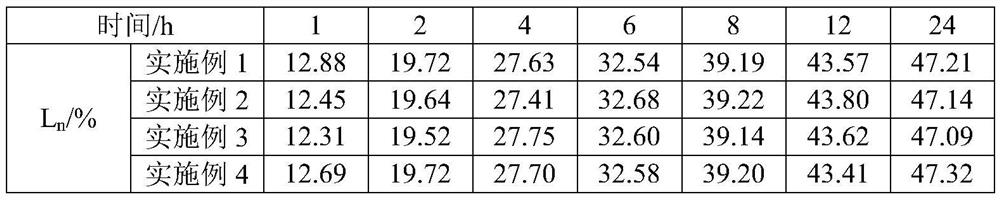

Embodiment 1

[0030] A preparation method for an external plaster for expelling rheumatism, comprising the following steps:

[0031] (1) Rubber production: Cut 181.8g of rubber into 12cm-long rubber strips after removing the film, put them in the rubber mixing machine and roll to obtain 0.4mm thick rubber flakes, and then add gasoline with 5.3 times the weight of the rubber flakes in the mixer The solvent is soaked at 10°C to fully swell and soften the rubber sheet. The soaking time is not less than 24 hours, preferably 24 hours. The gasoline solvent is preferably mixed with No. 120 gasoline and ethanol, and the volume percentage of No. 120 gasoline is 75%;

[0032] (2) Ingredients: add 10g of menthol, 20g of camphor, 15g of methyl salicylate, 10g of borneol, and 163.6g of rosin into ethanol and stir evenly, then add 23g of compound absorption enhancer, 7g of zinc oxide, and Aconitum aconiti Fluid extract 50g, belladonna fluid extract 30g, rue extract 12.5g, vaseline 27.3g stir to obtain th...

Embodiment 2

[0042] A preparation method for an external plaster for expelling rheumatism, comprising the following steps:

[0043] (1) Rubber production: Cut 227.4g of rubber into 16cm-long rubber strips after removing the film, put them in the rubber mixing machine and roll them to obtain 1.1mm thick rubber flakes, and then add gasoline with 8 times the weight of the rubber flakes in the mixer The solvent is soaked at 15°C to fully swell and soften the rubber sheet. The soaking time is not less than 24 hours, preferably 36 hours. The gasoline solvent is preferably mixed with No. 120 gasoline and ethanol, and the volume percentage of No. 120 gasoline is 90%;

[0044] (2) Ingredients: 12.5g of menthol, 25g of camphor, 19g of methyl salicylate, 12.5g of borneol, and 204.5g of rosin were added to ethanol in turn and stirred evenly, and then 34g of compound absorption-promoting agent, 9g of zinc oxide, raw Aconitum aconitum liquid extract 62.5g, belladonna liquid extract 37.5g, rue extract 15...

Embodiment 3

[0054] A preparation method for an external plaster for expelling rheumatism, comprising the following steps:

[0055] (1) Rubber production: Cut 250.8g of rubber into 18cm-long rubber strips after removing the film, put them in the rubber mixing machine and roll them to obtain 1.6mm thick rubber flakes, and then add gasoline with 9.3 times the weight of the rubber flakes in the mixer The solvent is soaked at 18°C to fully swell and soften the rubber sheet. The soaking time is not less than 24 hours, preferably 40 hours. The gasoline solvent is preferably mixed with No. 120 gasoline and ethanol, and the volume percentage of No. 120 gasoline is 90%;

[0056] (2) Ingredients: 13.8g of menthol, 27.5g of camphor, 21g of methyl salicylate, 13.8g of borneol, and 225g of rosin were added to ethanol and stirred evenly, and then 39.5g of compound absorption-promoting agent, 10g of zinc oxide, Aconitum aconitum liquid extract 68g, belladonna liquid extract 42g, rue extract 17g, vaseli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com