A process for microwave pyrolysis of waste tires to keep the cavity clean

A technology for maintaining cavities and waste tires, applied in chemical/physical/physicochemical processes of applied energy, petroleum industry, preparation of liquid hydrocarbon mixtures, etc., can solve problems such as interruption of operation, damage to microwave devices, breakdown, etc., and achieve reduction Pollution, guaranteed clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

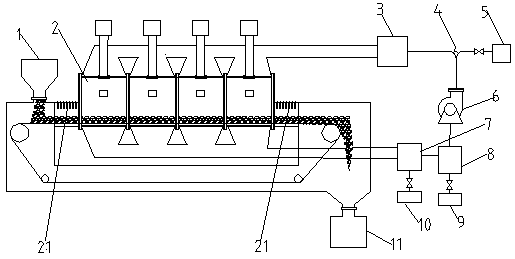

[0040] 1. A process for maintaining clean operation in the chamber for microwave pyrolysis of waste tires, comprising the following steps

[0041] A. Preparation before operation: Before starting operation, pass in the medium gas to discharge the oxygen in the system, and make the system pressure to normal pressure;

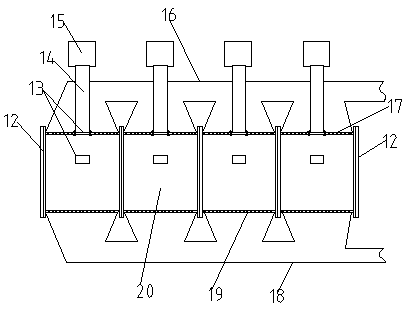

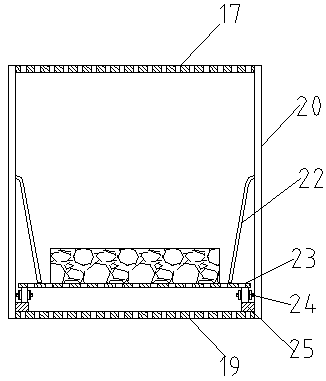

[0042] B. Microwave cracking: After starting to operate, the material is input into the microwave cracking chamber from the horizontal direction through the material conveying device and the material is located in the lower part of the microwave cracking chamber for microwave cracking. At the same time, the air inlet channel opened from the upper part of the microwave cracking chamber passes Entering the medium gas makes the medium gas move to the lower part of the cracking chamber, and drives the cracking mixed gas generated by cracking to pass through the material and exit the cracking chamber from the gas outlet opened at the bottom of the cracking chamber.

...

Embodiment 2

[0046] This embodiment is carried out with reference to Example 1, the difference is that the medium gas of this embodiment can be a single N 2 , hydrocarbon gas, CO, CO 2 、H 2 , It is also possible to use a mixture of two or more of the above-mentioned gases.

[0047] In this embodiment, the temperature of the medium gas is further limited, and the temperature of the medium gas is 350°C.

[0048] In this embodiment, in step B, the relationship between the medium gas and the cracked mixed gas generated by the cracking is defined. In this embodiment, the amount of the medium gas that passes into the cracking chamber per unit time is the cracked mixed gas produced. 1 times of that, the speed of the medium gas passing through the material in the modular cracking chamber is 0.1m / s.

Embodiment 3

[0050] The difference between this embodiment and embodiment 2 is that: the temperature of the medium gas is 700°C, the amount of the medium gas per unit time passed into the cracking chamber is 50 times the amount of the cracking mixed gas produced, and the medium gas is in the modular cracking chamber The speed of the material passing through the medium is 5m / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com