Preparation method for Ti3+/TiO2 photo-catalyst with hollow structure

A photocatalyst and hollow structure technology, applied in the field of environmental management, can solve problems such as reducing photocatalytic performance, achieve good recyclability, improve absorption and response, and reduce time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

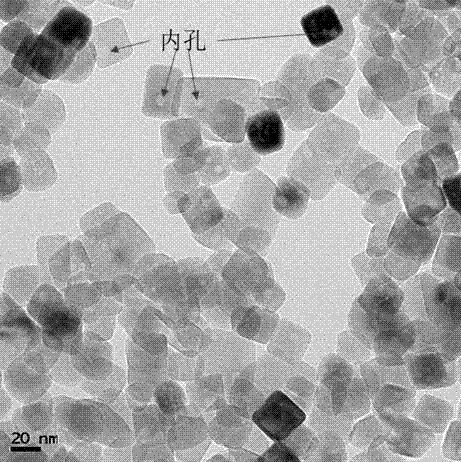

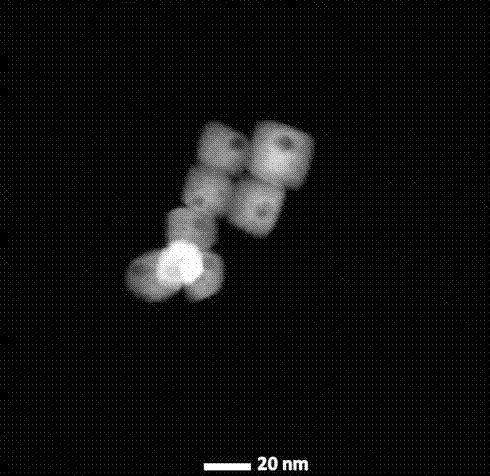

[0025] Mix 3.54 mL of glacial acetic acid, 0.35 mL of deionized water, and 4.372 mL of ionic liquid [Bmim][BF 4 ] mixed together. On this basis, 2 mL of tetrabutyl titanate was added dropwise to the previous mixed solution at a rate of 0.1 mL / s, and stirred during the whole process until the precursor solution became clear and transparent. The homogeneous solution was transferred to a 70 mL polytetrafluoroethylene reaction tank, and was heated in a microwave reactor (MDS-6, Shanghai Xinyi) at 150 o C was taken out after reacting for 1 hour, and the collected powder was cleaned three times with deionized water and absolute ethanol respectively, and placed in an oven for 60 o C drying, and finally placed in a vacuum oven at 200 o C heat treatment for 6 hours.

[0026] According to the XRD test of the synthesized catalyst, all the samples of microwave-assisted solvothermal synthesis have good crystallinity. The way of conduction to reactant molecules, the particularity of mic...

Embodiment 2

[0028] Mix 3.54 mL of glacial acetic acid, 0.35 mL of deionized water, and 4.372 mL of ionic liquid [Bmim][BF 4 ] mixed together. On this basis, 2 mL of tetrabutyl titanate was added dropwise to the previous mixed solution at a rate of 0.1 mL / s, and stirred during the whole process until the precursor solution became clear and transparent. The homogeneous solution was transferred to a 70 mL polytetrafluoroethylene reaction tank, and was heated in a microwave reactor (MDS-6, Shanghai Xinyi) at 150 o C was taken out after reacting for 1 hour, and the collected powder was cleaned three times with deionized water and absolute ethanol respectively, and placed in an oven for 60 o C drying, synthesis of TiO with a hollow structure 2 . The sample had a degradation rate of 72% for methylene blue under visible light with a wavelength greater than 400 nm within 120 minutes.

Embodiment 3

[0030] Mix 3.54 mL of glacial acetic acid, 0.35 mL of deionized water, and 4.372 mL of ionic liquid [Bmim]Cl. On this basis, 2 mL of tetrabutyl titanate was added dropwise to the previous mixed solution at a rate of 0.1 mL / s, and stirred during the whole process until the precursor solution became clear and transparent. The homogeneous solution was transferred to a 70 mL polytetrafluoroethylene reaction tank, and was heated in a microwave reactor (MDS-6, Shanghai Xinyi) at 150 o C was taken out after reacting for 1 hour, and the collected powder was cleaned three times with deionized water and absolute ethanol respectively, and placed in an oven for 60 o C drying, and finally placed in a vacuum oven at 200 o C heat treatment for 6 hours. The sample had a degradation rate of 44% for methylene blue under visible light with a wavelength greater than 400 nm within 120 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com