Microwave heating and atomizing cleaner

An atomization cleaning and microwave technology, which is applied in the field of cleaners, can solve the problems of cleaning residues of trace elements and impurities, and achieve the effects of short cleaning time, environmental protection in the cleaning process, and reduction in the amount of acid used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

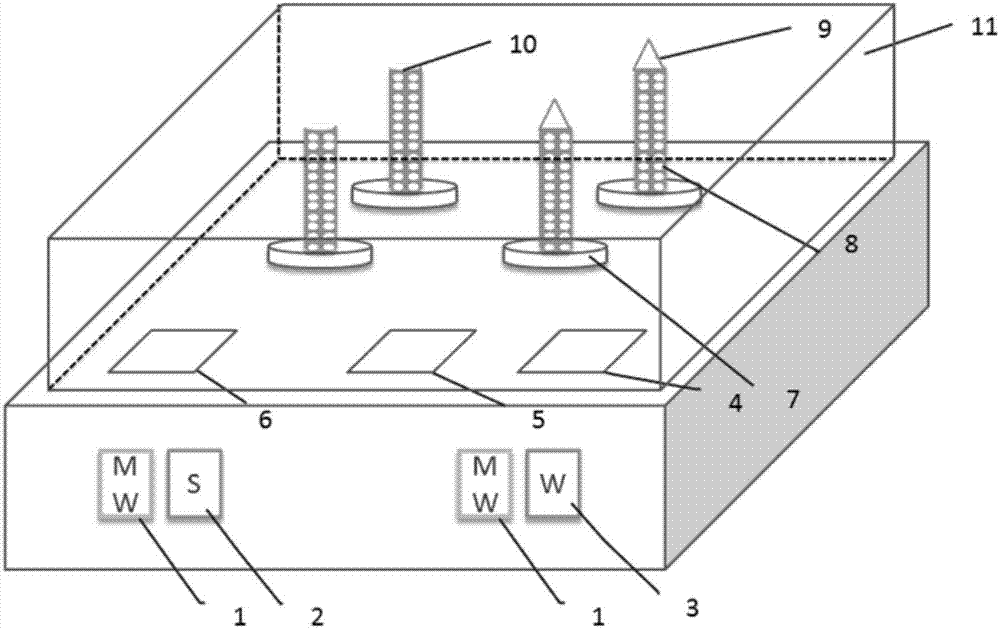

Embodiment 1

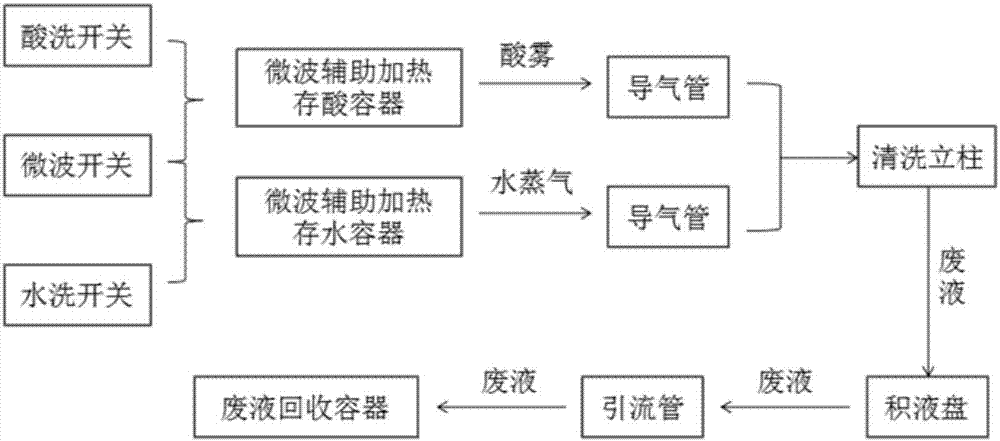

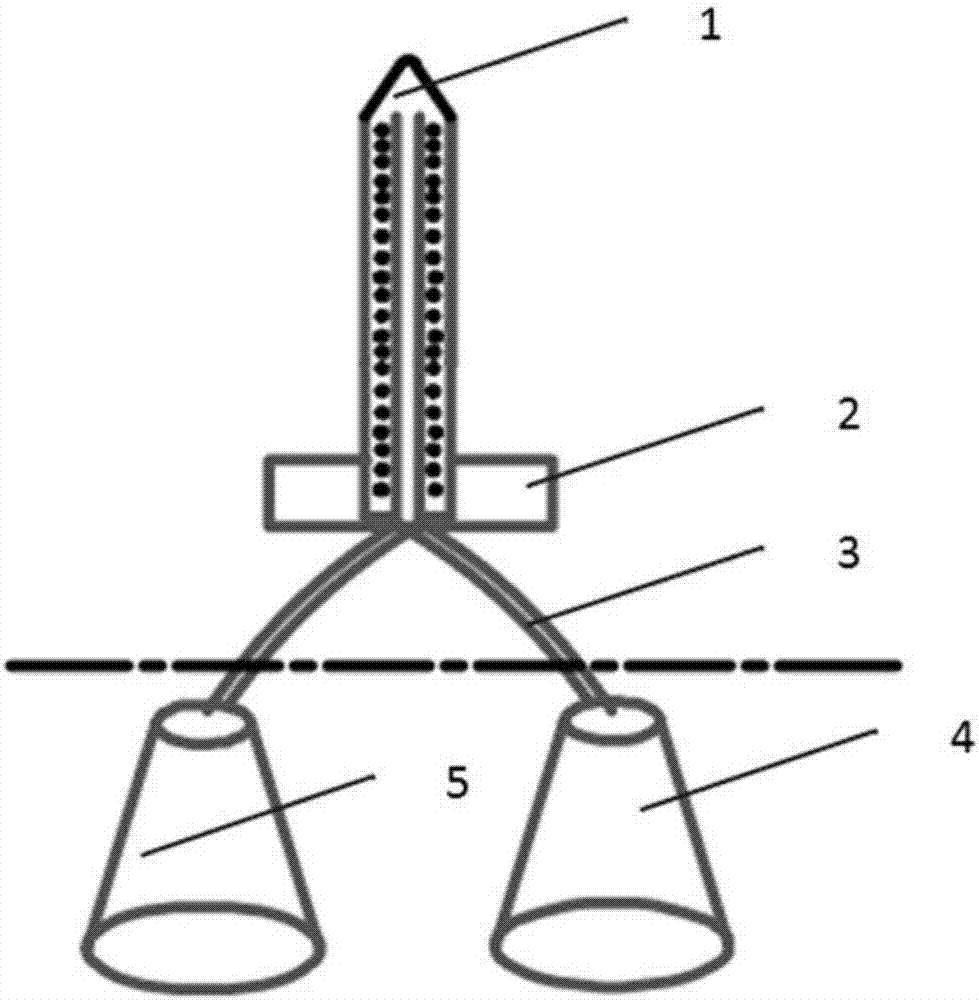

[0032] Put away the ready-to-wash utensils, cover the sealed cover, fill the container for storing nitric acid and the container for storing distilled water with concentrated nitric acid and distilled water respectively, turn on the pickling switch and the microwave generator switch next to it, and put the container containing nitric acid in the microwave-assisted Next, heat it with a graphite heating plate to boil and gasify the nitric acid. The nitric acid gas flow is sprayed out through the high-temperature acid-resistant and corrosion-resistant air duct. The inner wall of the container flows down to become waste acid, and the waste acid brings down the impurities together, and finally flows into the effusion tray, and the cleaning time is 2 minutes. Turn off the pickling switch, turn on the water washing switch and the microwave generator switch next to it, and clean it again with distilled water. The distilled water is heated with the aid of microwaves, boiled and gasified...

Embodiment 2

[0034] Put away the ready-to-wash utensils, cover the sealed cover, fill the container for storing nitric acid and the container for storing distilled water with concentrated nitric acid and distilled water respectively, turn on the pickling switch and the microwave generator switch next to it, and put the container containing nitric acid in the microwave-assisted Use a glass heating plate to heat the nitric acid to boil and gasify. The nitric acid flow is sprayed out through the high-temperature acid-resistant and corrosion-resistant air duct. The inner wall of the container flows down to become waste acid, and the waste acid brings down the impurities together, and finally flows into the effusion tray, and the cleaning time is 3 minutes. Turn off the pickling switch, turn on the water washing switch and the microwave generator switch next to it, and clean it again with distilled water. The distilled water is heated with the aid of microwaves, boiled and gasified, and the dist...

Embodiment 3

[0036] Put away the ready-to-wash utensils, cover the sealed cover, fill the container for storing nitric acid and the container for storing distilled water with concentrated nitric acid and distilled water respectively, turn on the pickling switch and the microwave generator switch next to it, and put the container containing nitric acid in the microwave-assisted Heat it with a metal heating plate to make the nitric acid boil and gasify. The nitric acid gas flow is sprayed out through the high-temperature acid-resistant and corrosion-resistant air duct. The inner wall of the container flows down to become waste acid, and the waste acid brings down the impurities together, and finally flows into the effusion tray, and the cleaning time is 5 minutes. Turn off the pickling switch, turn on the water washing switch and the microwave generator switch next to it, and clean it again with distilled water. The distilled water is heated with the aid of microwaves, boiled and gasified, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com