Method for preparing high-purity sulfur-containing products in a short process of molybdenum concentrate

A molybdenum concentrate, short-process technology, applied in the preparation/purification of sulfur, sulfur compounds, chemical instruments and methods, etc., can solve the prominent contradiction between the seasonal consumption of sulfuric acid and the stable and balanced production, the heavy environmental protection burden of molybdenum metallurgy enterprises, Poor sales affect production stability and other issues, and achieve good application prospects, improve application value, and achieve considerable economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

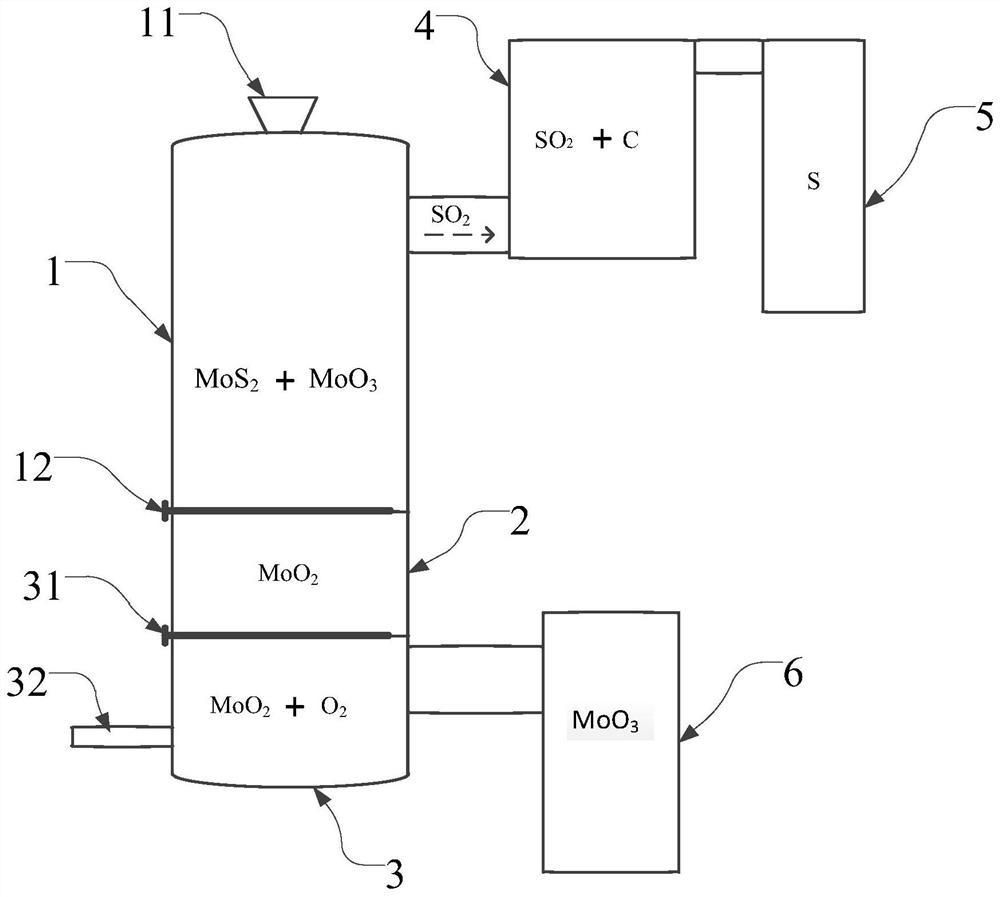

[0051] figure 1 Schematic diagram of the device for preparing high-purity sulfur in the short process flow of molybdenum concentrate disclosed in Example 1.

[0052] The device for preparing high-purity sulfur in a short process of molybdenum concentrate disclosed in Example 1 includes a reactor 1 for setting molybdenum concentrate raw materials and molybdenum trioxide raw materials. Above the reactor 1, a material feeding port 11 is provided, and a material feeding port 11 is provided. A sealable cover is provided to seal it, and the reaction materials molybdenum concentrate and molybdenum trioxide can enter the reactor 1 from the material feeding port 11 for reaction; the upper side of the reactor 1 is provided with a sulfur dioxide gas outlet, which is connected to The pipe is communicated with the replacement furnace 4, and the carbonaceous reducing agent is used in the replacement furnace 4, and the produced sulfur dioxide gas enters the replacement furnace 4 to react wit...

Embodiment 2

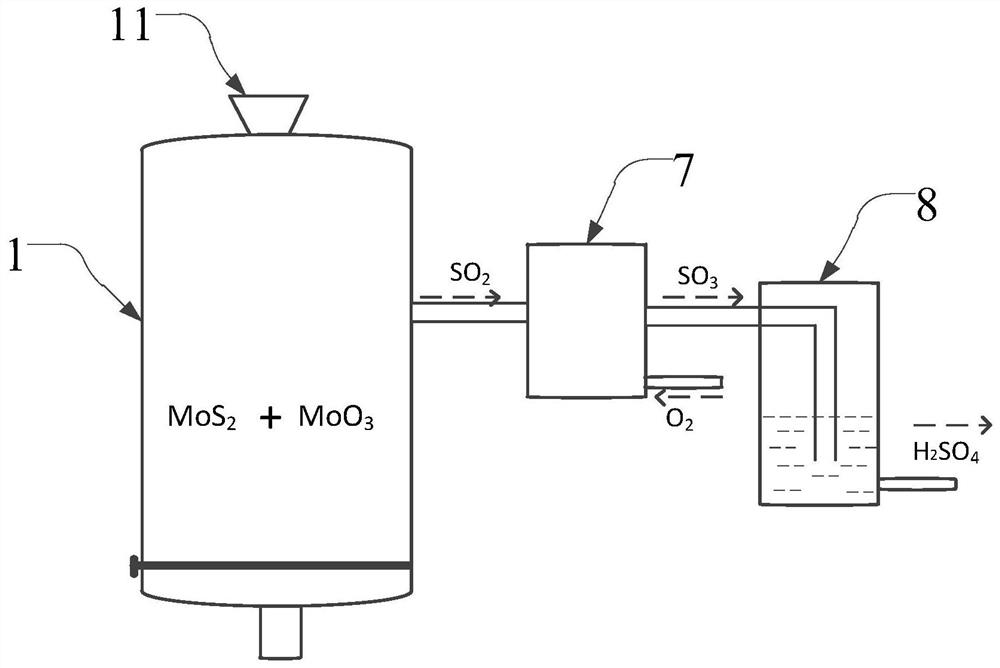

[0057] figure 2 Schematic diagram of the device for preparing high-purity sulfuric acid in the short process of molybdenum concentrate disclosed in Example 2.

[0058] The device for preparing sulfuric acid in a short process of molybdenum concentrate disclosed in Example 2 includes a reactor 1 for setting molybdenum concentrate raw materials and molybdenum trioxide raw materials. A material feeding port 11 is provided above the reactor 1, and the material feeding port 11 is provided with The cover body can be sealed to seal it, and the reaction materials molybdenum concentrate and molybdenum trioxide can enter the reactor 1 from the material feeding port 11 for reaction; the reactor 1 is provided with a sulfur dioxide gas outlet, which is connected to the reformer through a communication pipe. 7 is connected, and oxygen is used to oxidize sulfur dioxide into sulfur trioxide in the reformer 7;

[0059] The method for preparing high-purity sulfur-containing products from moly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com