A microwave sintering method of industrial waste slag light ceramsite

A technology of microwave sintering and lightweight ceramsite, applied in the field of building materials, can solve the problems of long sintering time of waste incineration ash ceramsite, poor uniformity of sintered products, high energy consumption, etc. The effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 25% of garbage incineration ash, 25% of sludge, 5% of chromium residue, 35% of clay and 10% of carbon black by weight, mix them; put them into a ball mill and grind them to less than 100 microns; then put them into a drum granulator, Atomize and spray water accounting for 14% to 25% of the weight of the powder, and prepare the material into spherical balls of 5 to 20 mm by stirring and rolling granulation; place the prepared balls in a drying box, Dry at 105°C for 12 hours.

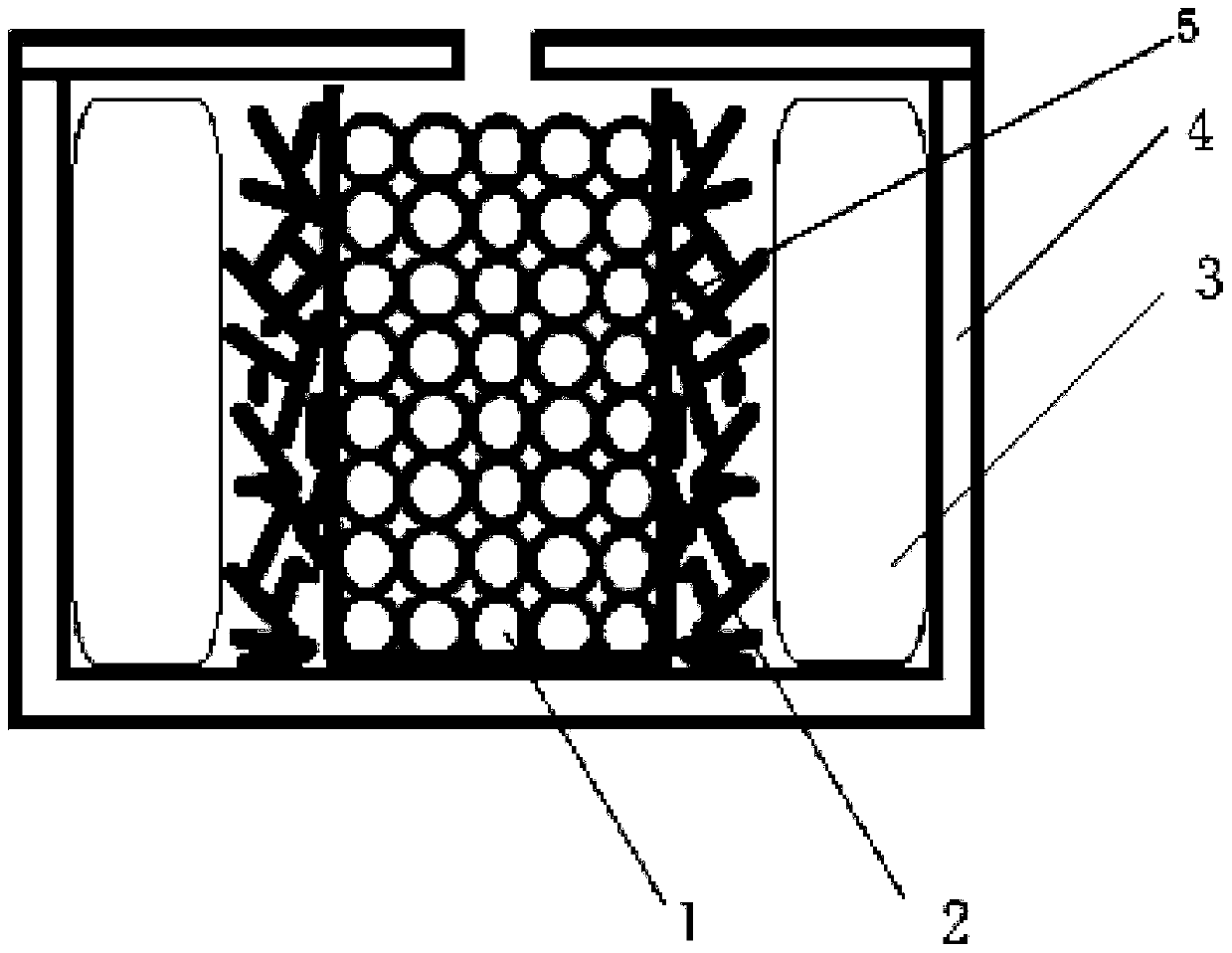

[0022] Put the dried pellets into the crucible with sintered insulation structure, such as figure 1 As shown, then put the sintered heat preservation structure into the heating chamber of the microwave sintering furnace for sintering; the microwave frequency of the microwave sintering furnace is 2.45GHZ, when the temperature rises to 1100°C, keep it warm for 10 minutes; after the heat preservation is over, wait for the material to cool naturally Remove from room temperature.

[0023] The app...

Embodiment 2

[0025] Get garbage incineration ash 25%, sludge 40%, chrome slag 5%, clay 20% and carbon black 10% by weight; Microwave sintering temperature is 1200 ℃, holding time 10 minutes; All the other are the same as embodiment 1, get light pottery grain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com