Sectional sludge drying system

A sludge drying and segmented technology, applied in sludge treatment, pyrolysis sludge, water/sludge/sewage treatment, etc., can solve the problems of low drying efficiency, poor economy, secondary pollution, etc. , to achieve the effect of recycling, increasing the total surface area, and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

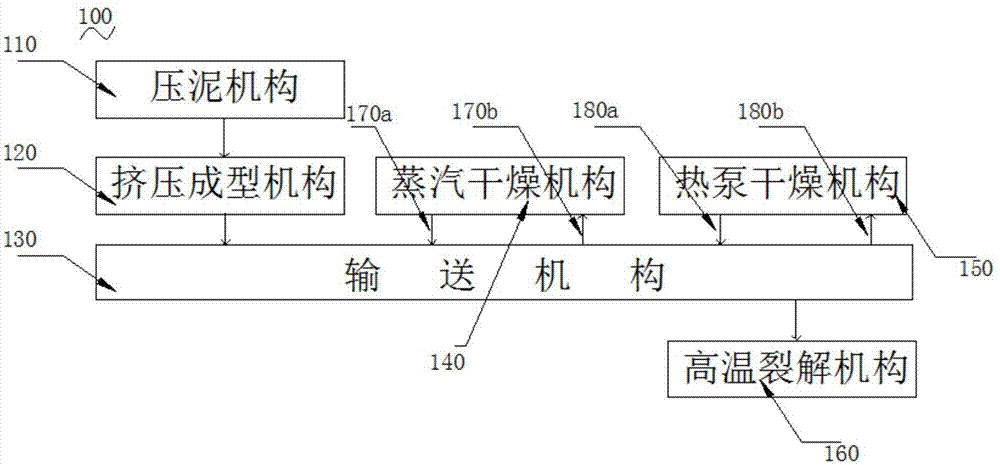

[0034] like figure 1 Shown is the structural principle diagram of the present invention.

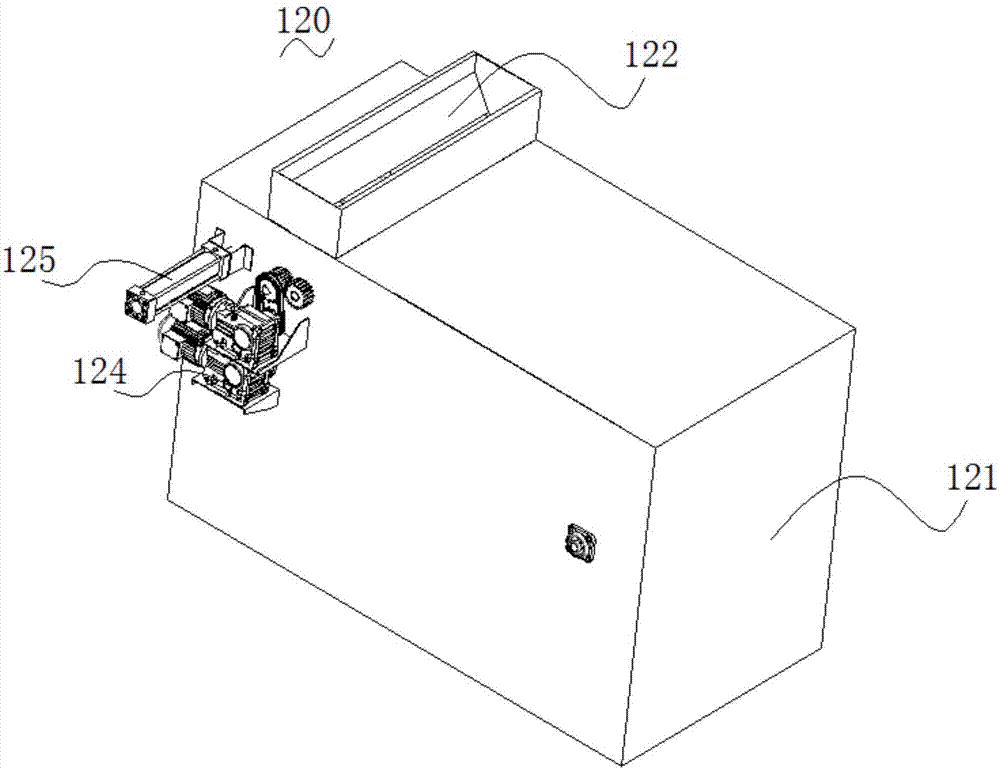

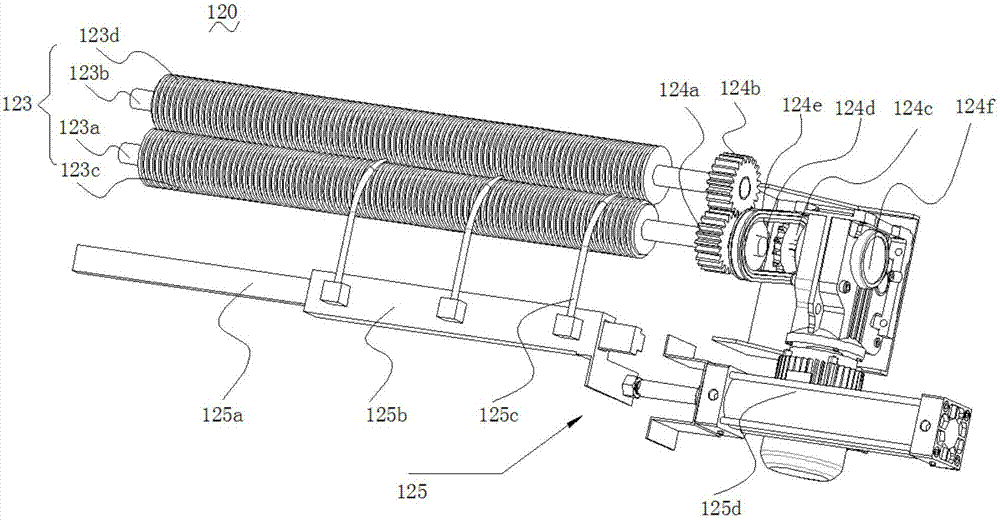

[0035] The segmented sludge drying system 100 includes a mud pressing mechanism 110 for dewatering the sludge, and an extrusion molding machine for extruding the dehydrated block or powder or sludge sludge into strip sludge. Mechanism 120, conveying mechanism 130 for transporting sludge, steam drying mechanism 140 for primary drying of sludge, heat pump drying mechanism 150 for secondary drying of sludge, high temperature pyrolysis of sludge The pyrolysis mechanism 160. The extrusion forming mechanism 120 is located below the mud pressing mechanism 110, the conveying mechanism 130 is located below the extruding forming mechanism 120, the steam drying mechanism 140 and the heat pump drying mechanism 150, and the conveying mechanism 130 passes through the first air inlet pipe 170...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com