Antirust agent for autoclaved aerated concrete plate reinforcements and preparation method thereof

An autoclaved air-entraining and concrete technology, which is applied in the field of rust inhibitor, can solve the problems of the rust inhibitor and the unsatisfactory adhesion, and achieves low production cost, simple preparation method and process, guaranteed service life and safe use. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

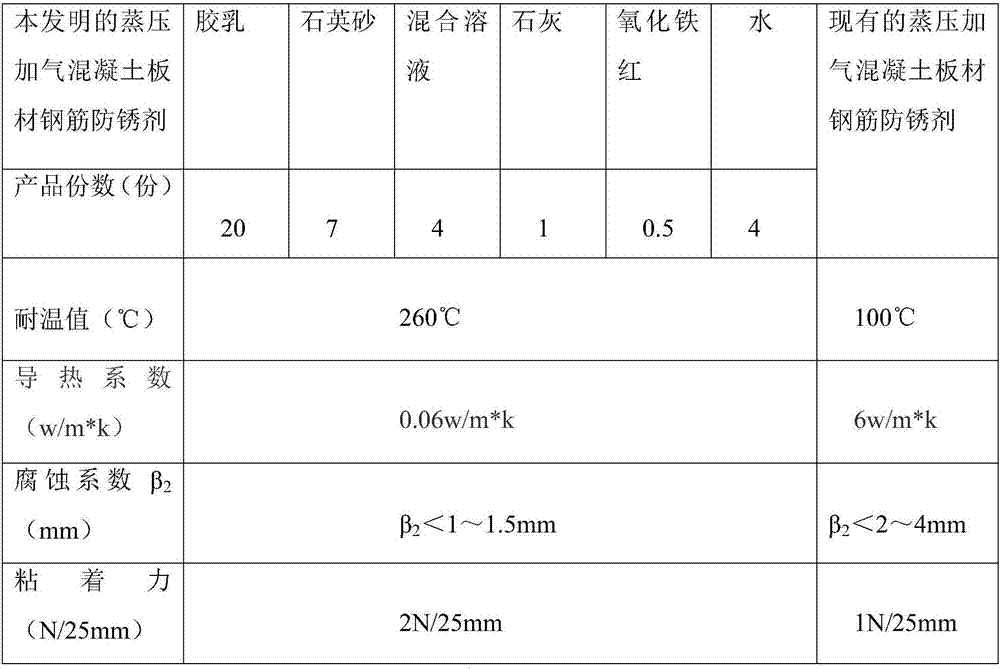

Embodiment 1

[0037] The autoclaved aerated concrete slab reinforcement rust inhibitor of the present invention comprises 20-30 parts of latex, 7-8 parts of quartz sand, 4-5 parts of mixed solution, 1-2 parts of lime, 0.5-1 part of iron oxide red, and water 2 to 3 servings. Wherein said mixed solution comprises 0.1-0.3 parts of sodium hydroxide, 0.1-0.3 parts of thickening agent and 4-5 parts of water.

[0038] When the present invention is concretely implemented, described latex preferably adopts that density is 1kg / m 3 , Viscosity of 500mpa s hydroxybutadiene latex to achieve. And described lime then preferably adopts relative density to be 2.5kg / m 3 , slaked lime with a melting point of 5320°C and a pH of 12.6. At the same time, the iron oxide red is preferably used with a relative density of 52.3kg / m 3 , Synthetic iron oxide red with a fineness of 8um and a melting point of 1650°C. The described tackifier preferably adopts an oily tackifier with a relative molecular weight of 1600 ...

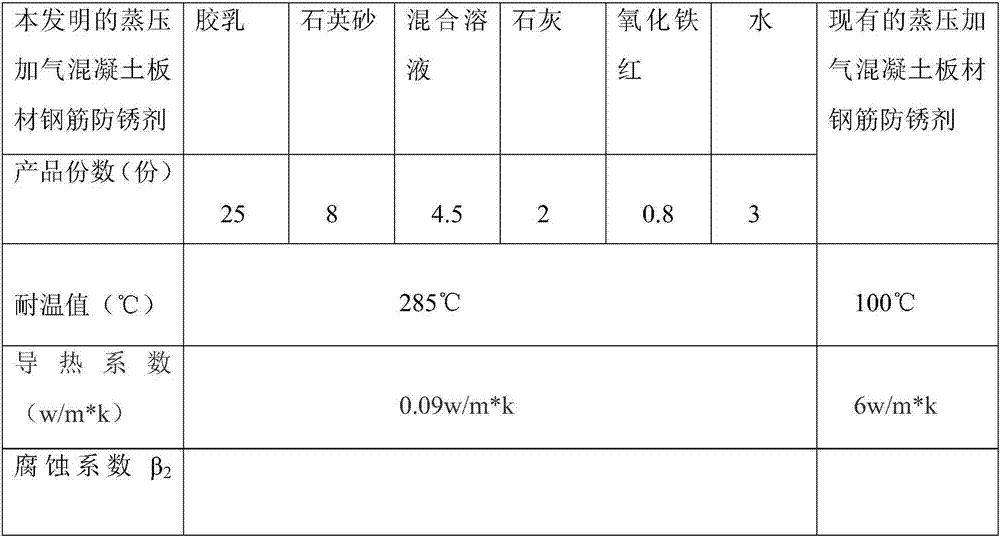

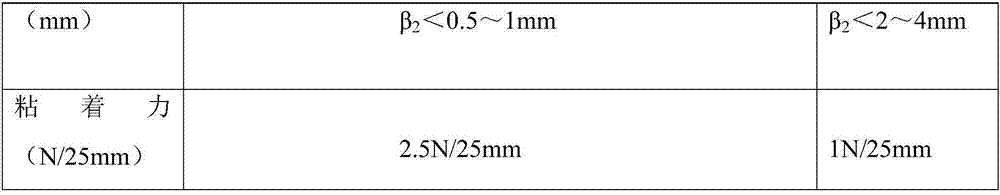

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, the difference is:

[0049] The latex in the present embodiment is 25 parts, the quartz sand is 8 parts, the mixed solution is 4.5 parts, the lime is 2 parts, the iron oxide red is 0.8 part, and the water is 3 parts. And the sodium oxide in the mixed solution is 0.1 part, the tackifier is 0.2 part, and the water is 4.5 parts.

[0050] The preparation method of the autoclaved aerated concrete slab steel bar antirust agent of the present embodiment is basically the same as the preparation method of embodiment 1, and its difference is:

[0051] When adding slaked lime to the latex after stirring in this embodiment, the mixer is controlled to stir clockwise at a speed of 1500 min for 8 min, then settle for 5 min, and then stir counterclockwise at a speed of 800 r / min for 8 min. After mixing sodium hydroxide, tackifier and water in advance, and stir with a mixer at a speed of 150r / min for 10min to obtain a mixed solutio...

Embodiment 3

[0053] This embodiment is basically the same as Embodiment 1, the difference is:

[0054] The latex in the present embodiment is 30 parts, the quartz sand is 7.5 parts, the mixed solution is 5 parts, the lime is 1.5 parts, the iron oxide red is 1 part, and the water is 2.5 parts. And the sodium oxide in the mixed solution is 0.2 parts, the tackifier is 0.1 parts, and the water is 5 parts.

[0055] The preparation method of the autoclaved aerated concrete slab steel bar antirust agent of the present embodiment is basically the same as the preparation method of embodiment 1, and its difference is:

[0056] In this embodiment, when slaked lime is added to the homogenized latex for stirring, the mixer is controlled to stir clockwise at a speed of 2000 min for 10 min, then settle for 5 min, and then stir counterclockwise at a speed of 1000 r / min for 10 min. After mixing sodium hydroxide, tackifier and water in advance, and stir with a mixer at a speed of 200r / min for 8min to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com