Super-hydrophobic coating, preparation method and application of super-hydrophobic coating

A technology of super-hydrophobic coating and application method, applied in the field of super-hydrophobic coating and the preparation of the above-mentioned super-hydrophobic coating, can solve problems such as poor durability, and achieve the effects of good durability, stable hydrophobic performance and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

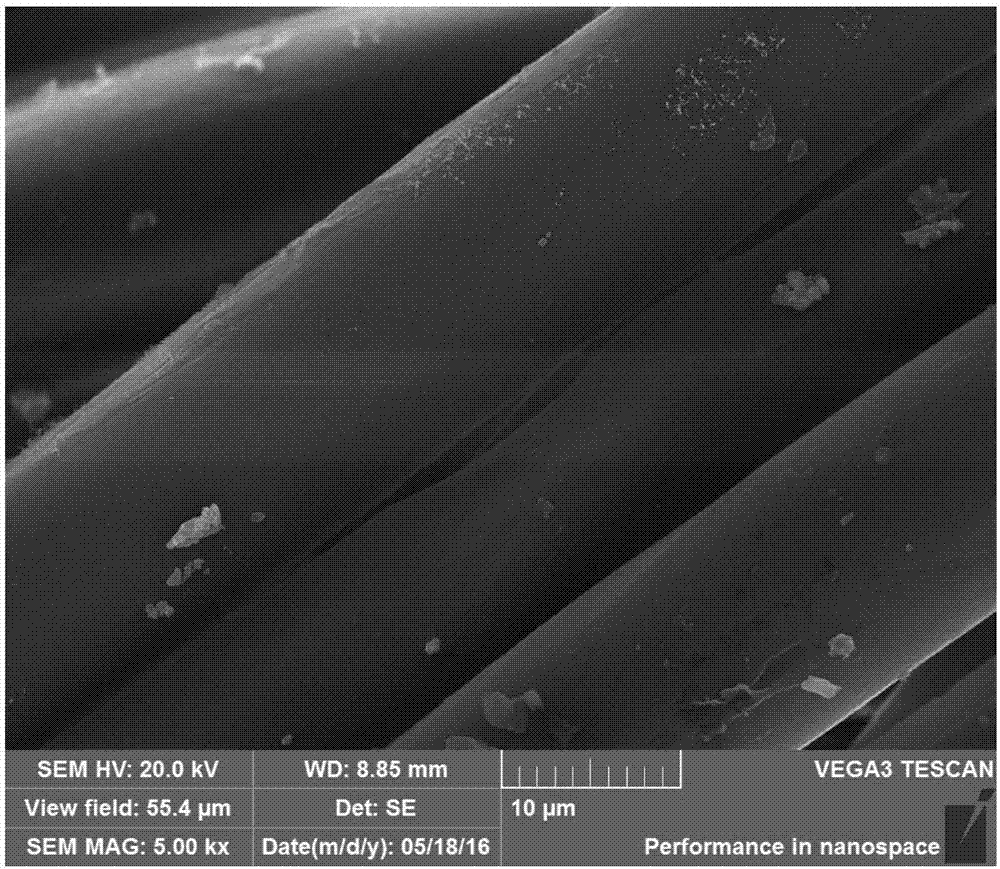

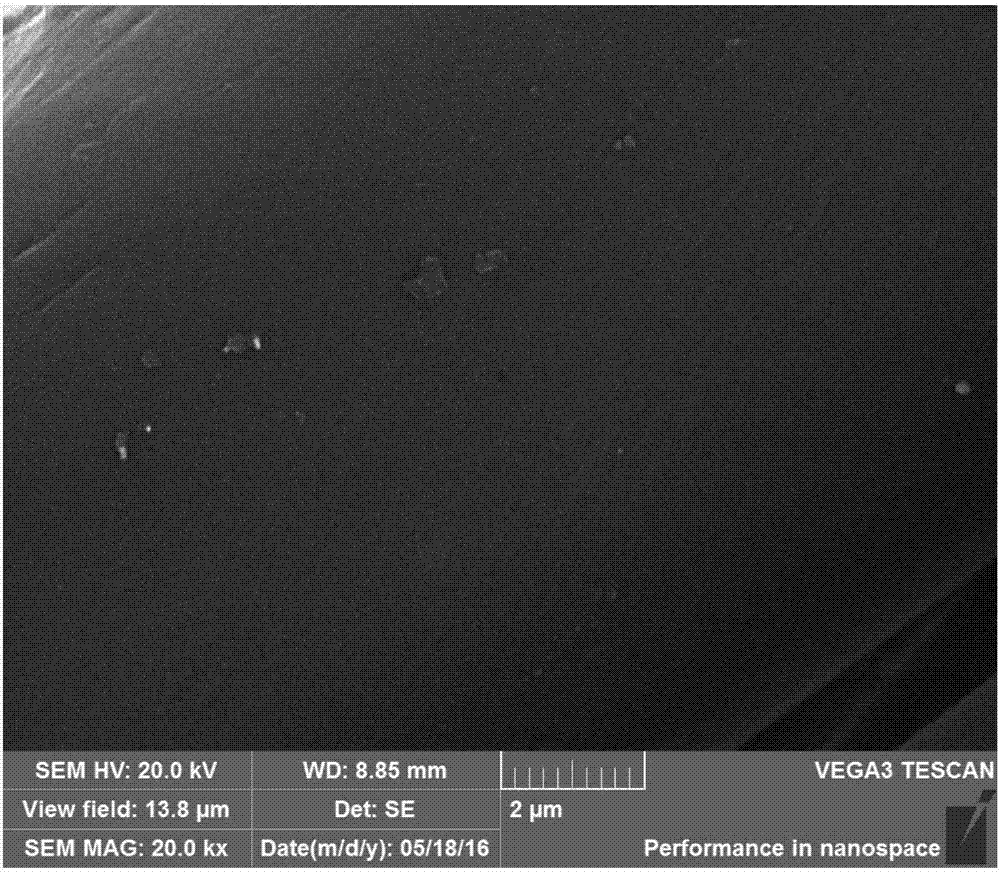

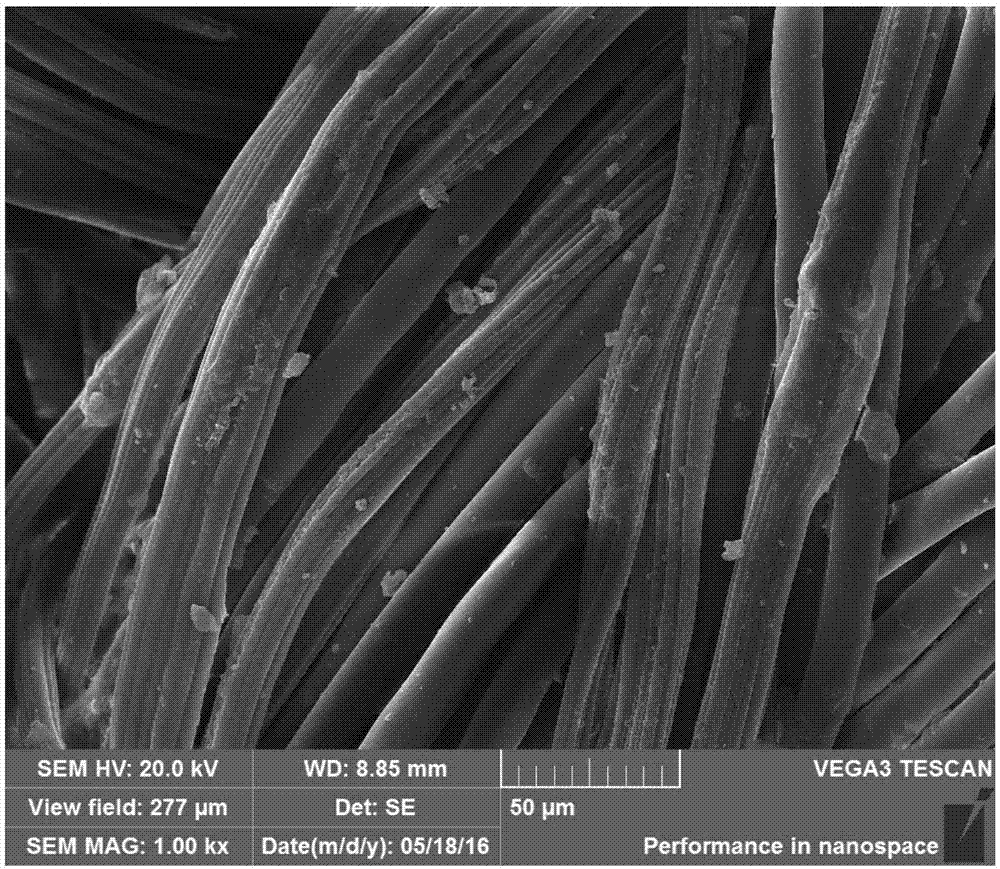

Image

Examples

preparation example Construction

[0047] A kind of preparation method of superhydrophobic coating of the present invention, specifically implement according to the following steps:

[0048] Step 1. Take glycidyl methacrylate (GMA), and filter the glycidyl methacrylate (GMA) with an alumina chromatography column to remove the polymerization inhibitor.

[0049] Step 2. Weighing dodecafluoroheptyl methacrylate (DFMA), glycidyl methacrylate (GMA) treated in step 1 and Azobisisobutyronitrile and sodium bisulfite;

[0050] Among them, dodecafluoroheptyl methacrylate (DFMA) and glycidyl methacrylate (GMA) are used as raw materials, and azobisisobutyronitrile and sodium bisulfite are used as initiators.

[0051] Step 3. Add all the materials weighed in step 2 into the container together, then add tetrahydrofuran into the container, seal the container and pass nitrogen gas for 45min to 55min, the purpose is to discharge the oxygen in the container;

[0052] Wherein, tetrahydrofuran is a solvent, nitrogen is a protectiv...

Embodiment 1

[0072] Preparation method of superhydrophobic coating:

[0073] Take glycidyl methacrylate (GMA), and filter the glycidyl methacrylate (GMA) with an alumina chromatography column to remove the polymerization inhibitor; weigh 10% methacrylic acid respectively according to the molar ratio of 9:1:0.06:0.1 Difluoroheptyl ester (DFMA), treated glycidyl methacrylate (GMA), and azobisisobutyronitrile and sodium bisulfite; add all weighed materials together to a round-bottomed flask, and add to the round-bottomed flask Add tetrahydrofuran to the flask, seal the round-bottomed flask and ventilate nitrogen for 45 minutes to discharge the oxygen in the round-bottomed flask; place the whole round-bottomed flask in an oil bath constant temperature pot with a temperature of 65°C and heat it under the protection of nitrogen Turn on the magnetic stirring for 35 minutes to fully react the dodecafluoroheptyl methacrylate (DFMA), glycidyl methacrylate (GMA), azobisisobutyronitrile and sodium bis...

Embodiment 2

[0080] Preparation method of superhydrophobic coating:

[0081] Take glycidyl methacrylate (GMA), and filter the glycidyl methacrylate (GMA) with an alumina chromatography column to remove the polymerization inhibitor; weigh 10% methacrylic acid according to the molar ratio of 8:1:0.05:0.15. Difluoroheptyl ester (DFMA), treated glycidyl methacrylate (GMA), and azobisisobutyronitrile and sodium bisulfite; add all weighed materials together to a round-bottomed flask, and add to the round-bottomed flask Add tetrahydrofuran to the flask, seal the round-bottom flask and pass nitrogen gas for 55 minutes, and discharge the oxygen in the round-bottom flask; place the whole round-bottom flask in an oil bath constant temperature pot with a temperature of 75°C and heat it under the protection of nitrogen. Turn on the magnetic stirring for 45 minutes to fully react the dodecafluoroheptyl methacrylate (DFMA), glycidyl methacrylate (GMA), azobisisobutyronitrile and sodium bisulfite in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com