Critical medium injection oil shale single-well huff and puff transformation process

A medium oil and oil shale technology is applied in the field of single well huff and puff conversion process of critical medium oil shale. , the effect of accelerated aging and extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

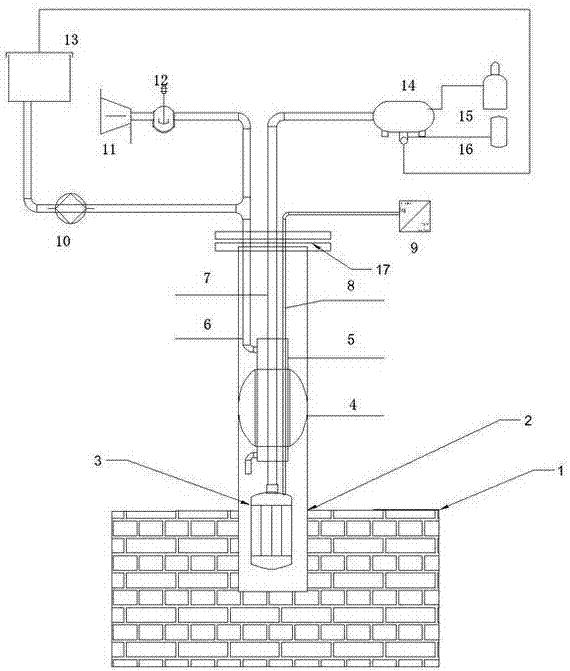

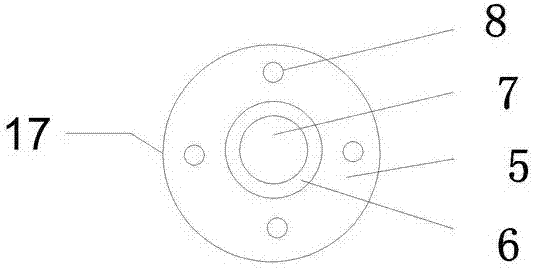

[0021] Example 1: if figure 1 As shown, the specific steps of this embodiment are as follows:

[0022] The buried depth of oil shale in a certain place is 410-420m, the thickness of oil shale in the target layer is 9m, the oil content is 5.73%, the ash content is 83%, the volatile matter content is 18.26%, and the calorific value is 3998.31J / g.

[0023] (1) Drilling and completion:

[0024] a. Determine the position of the working well according to the direction and horizon of the oil shale;

[0025] b. Drill a working well on the ground with a diameter of 346mm, and run a casing of 244.5mm at 0-422m. The end of the casing is run into floating hoops and floating shoes, and elastic centralizers are fixed every 20m outside the casing; casing and well Cementing with cement slurry between the walls;

[0026] c. Perform perforation at a hole depth of 409-422m to improve the permeability of oil shale around the working well;

[0027] (2) Equipment installation and preliminary wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com