Preparation technology and application of special salt for raw-marinated vegetables

A preparation process and vegetable technology, which is applied in the field of special raw brine vegetable salt preparation industry, can solve the problems of reducing the brittleness of brine vegetables, and achieve the effects of pure brine, convenient use and short processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

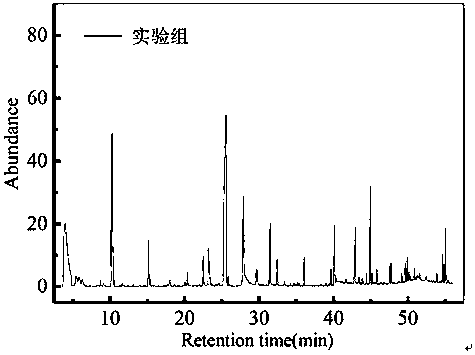

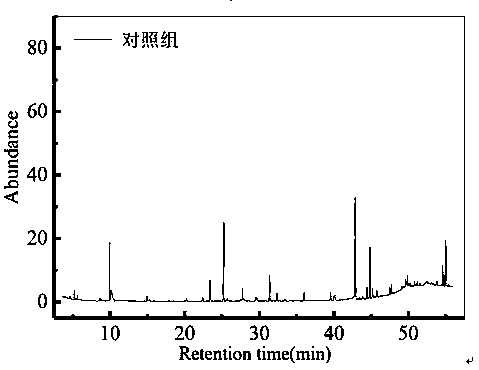

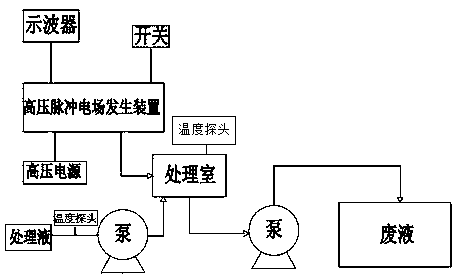

Image

Examples

Embodiment 1

[0043] The preparation process of special raw marinated vegetable salt comprises the following steps:

[0044] 1. Preparation of raw materials

[0045] (1) 1500g of fresh chicken skeleton, 350g of beef bone and 550g of pig bone are pulverized into bone paste by a pulverizer for subsequent use;

[0046] (2) Mix and chop fresh shiitake mushrooms, fresh mushrooms, and fresh oyster mushrooms with a mass ratio of 1:1:1, then mix them with distilled water at a mass ratio of 1:6.5, and use a beater to make a mushroom homogenate for later use;

[0047] (3) Chicken fat, butter and lard are boiled separately and cooled for later use;

[0048] (4) Weigh the auxiliary materials in proportion: 22g dried chili, 14.6g red pepper, 15.5g star anise, 35.2g green pepper, 1.8g fragrant leaves, 1.1g cloves, 4.7g tangerine peel, 2.1g cinnamon, 2.8g dill seeds, 12g of Angelica dahurica, 2.1g of three Nye, 18.4g of cinnamon, 1g of white pepper, 15.5g of rock sugar, and 11g of white sugar, respectiv...

Embodiment 2

[0053] The preparation process of special raw marinated vegetable salt comprises the following steps:

[0054] 1. Preparation of raw materials

[0055] (1) 1200g of fresh chicken skeleton, 450g of beef bone and 750g of pig bone are pulverized into bone paste by a pulverizer for subsequent use;

[0056] (2) Mix and chop fresh shiitake mushrooms, fresh mushrooms, and fresh oyster mushrooms with a mass ratio of 0.8:1.2:1, then mix them with distilled water at a mass ratio of 1:7.2, and use a beater to make a mushroom homogenate for later use;

[0057] (3) Chicken fat, butter and lard are boiled separately and cooled for later use;

[0058] (4) According to the weight of the auxiliary materials: 23.5g dried chili, 11.6g red pepper, 12.6g star anise, 33.5g green pepper, 1.6g fragrant leaves, 1.0g clove, 3.9g tangerine peel, 2.1g cinnamon, 2.3g dill seeds, 9.6g of Angelica dahurica, 1.8g of three Nye, 22g of cinnamon, 0.8g of white pepper, 12.5g of rock sugar, and 10g of white sug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com