Construction method capable of reducing roof cutting depth of gob-side entry retaining

A technology of retaining an empty entry and depth, which is applied in earthwork drilling, discharge machinery, ground mining, etc. It can solve the problems of weakening blasting effect and achieve the effect of improving maintenance effect, reducing construction cost and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

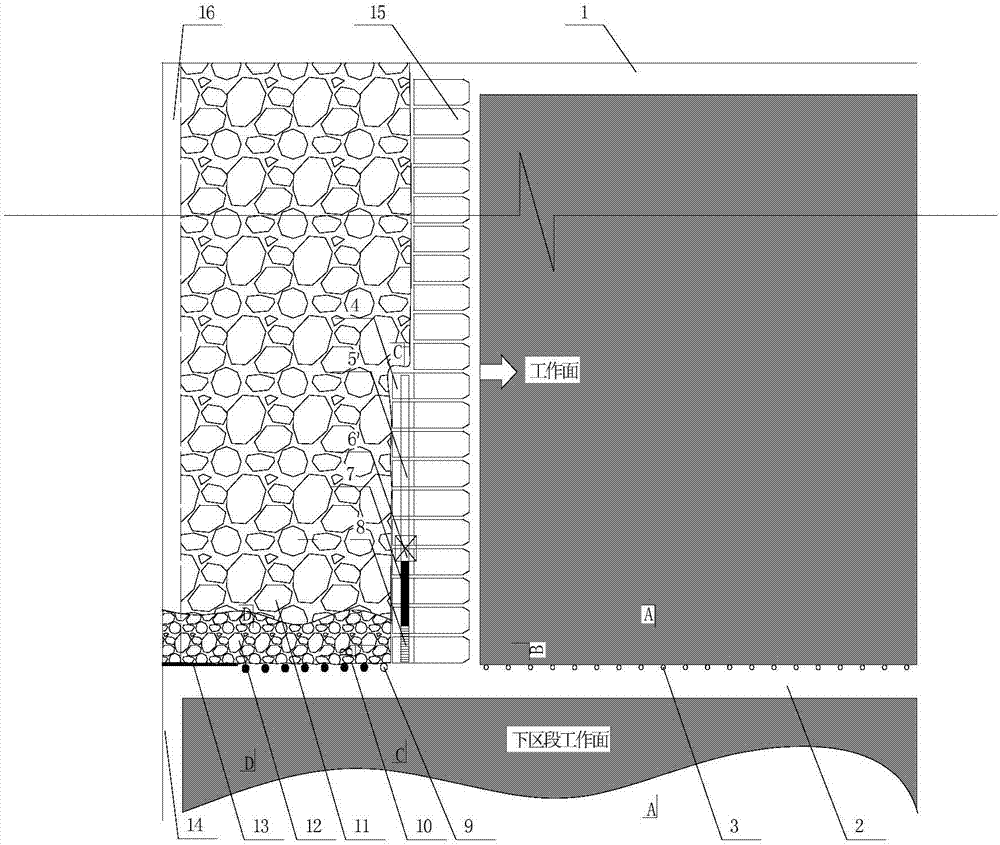

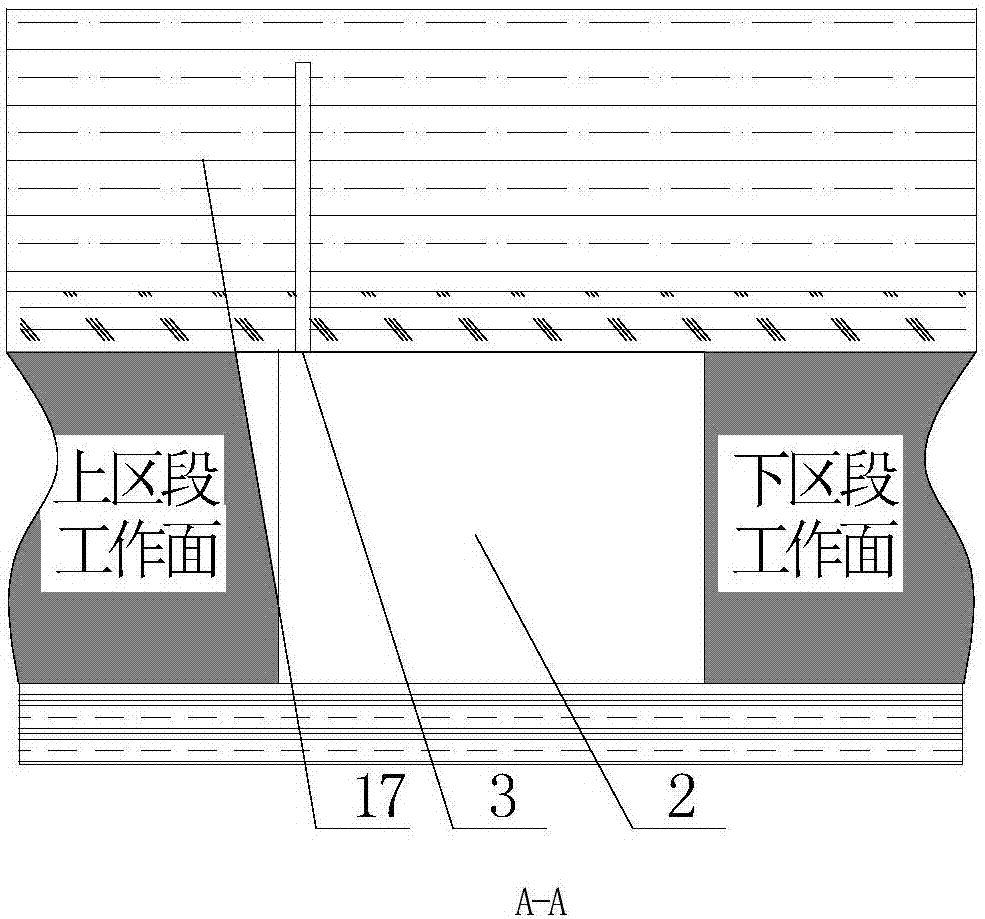

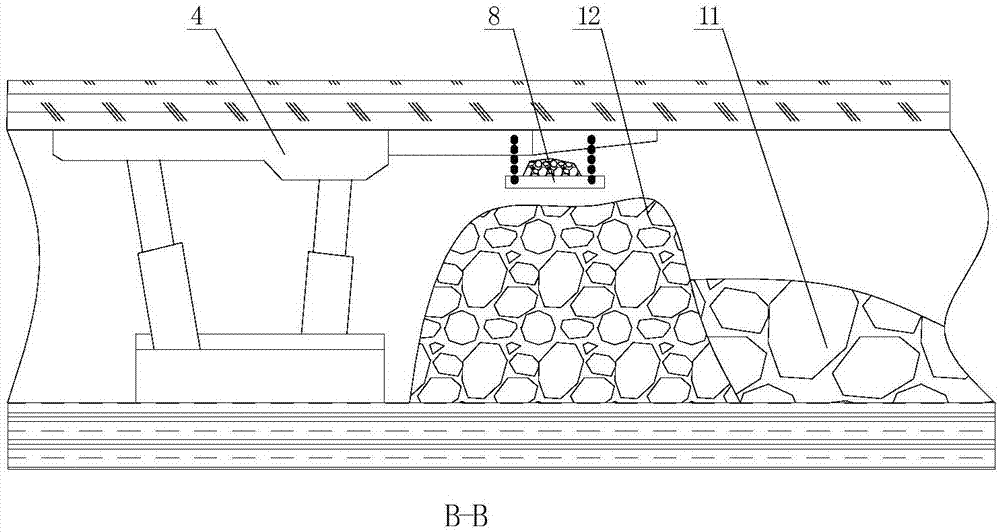

[0028] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0029] The method for reducing the depth of roof cutting in gob-side entry retention in medium-thick coal seams of the present invention comprises the following steps:

[0030] a. Excavate the main air inlet lane 1, the auxiliary air inlet lane 2, the cut hole 16 and the air return lane 14 of the working face to form a working face recovery system;

[0031] b. Auxiliary air inlet lane 2 in front of the working face is adjacent to the top-cutting blast hole in the roof construction of the mining side. Directional energy-gathering ring blasting is adopted. The depth of the blast hole 3 is determined according to the equivalent mining height and the gob gangue compaction rate. Orientate the pre-splitting roof along the direction of the auxiliary air inlet 2, and adopt the existing longwall working face mining method without coal pillars; the diameter of the bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com