Corrosion-resistant cut-off valve

A cut-off valve and corrosion-resistant technology, applied in the field of invention, can solve problems such as casualties, property loss, and reduced sealing effect, and achieve the effects of improved sealing and aging resistance, accurate and safe data, and good diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

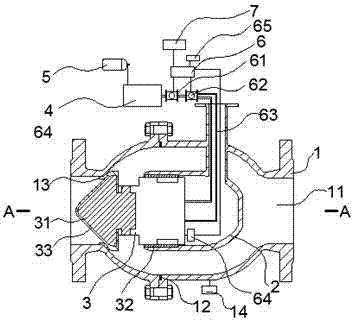

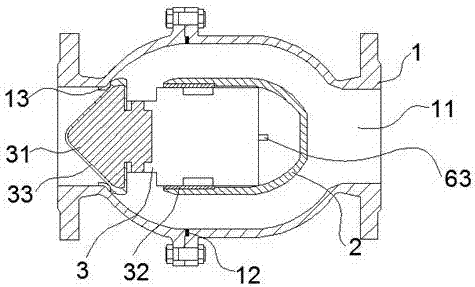

[0021] like Figure 1~6 As shown, the corrosion-resistant cut-off valve includes a valve body 1. The valve body 1 is formed by connecting upper and lower parts. A sealing ring 12 is provided at the joint. An annular block 12a is provided in the middle of the sealing ring 12. An elastic Bending plate, the valve core 2 placed in the center of the valve body 1, the volume ratio of the valve core 2 to the volume of the valve cavity 11 is preferably 0.48:1, the valve body 1 is connected to the upper part of the tail end of the valve core 2 through a connecting pipe, and the valve core 2. The cross section is "U" shape. The inner side of the top of the valve core 2 is connected with the hydraulic cylinder 3 through the seal sleeve 32. The front of the hydraulic cylinder 3 is connected with the piston 31. The valve body 1 is equipped with an arc-shaped plug that cooperates with the piston 31. Block 13, hydraulic cylinder 3 is connected with flow control valve 62 and proportional ampl...

Embodiment 2

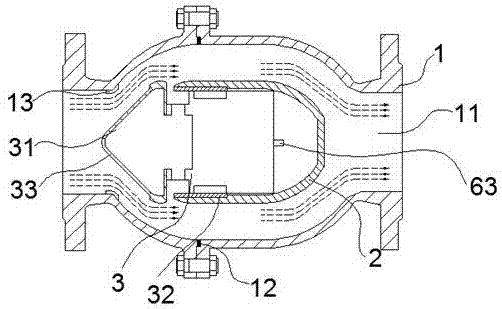

[0025] like Figure 1~6As shown, when the cut-off valve of the present invention transmits medium, the center of the valve core 2 coincides with the center of the valve body 1, and the medium flows in the valve cavity 11. When the medium passes through the piston 31, the single-piston rod hydraulic cylinder 3 is used to realize the reciprocating motion. The deceleration device can be eliminated, there is no transmission gap, and the movement is stable. Since the piston 31 and the sealing surface 33 are conical, it can play a role in diverting the medium, and the surface of the piston 31 is covered with the sealing surface 33, which is resistant to Good abrasion resistance, good sealing performance, good resistance to corrosion, oxidation and wear during the transportation of medium, can reduce flow resistance, the medium passes through the valve chamber 11 in a ring shape, so that the split flow should be smooth and there will be no turbulent flow and vibration and the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com