Method for separation, analysis and identification of reductively released glycoprotein n-glycan and its derivatives

A technology for glycoproteins and derivatives, applied in the field of glycobiology, can solve problems such as easy decomposition, unstable N-glycan chains, unfavorable analysis, etc., and achieve the effects of less side reactions, improved detection sensitivity, and strong versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

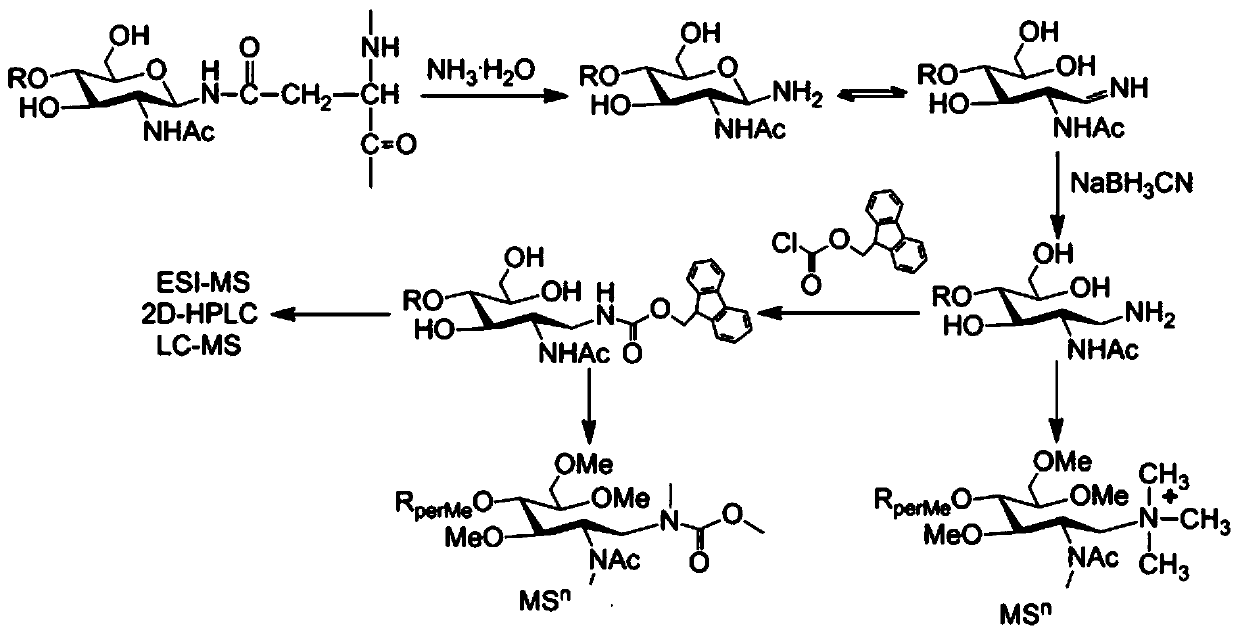

Method used

Image

Examples

Embodiment 1

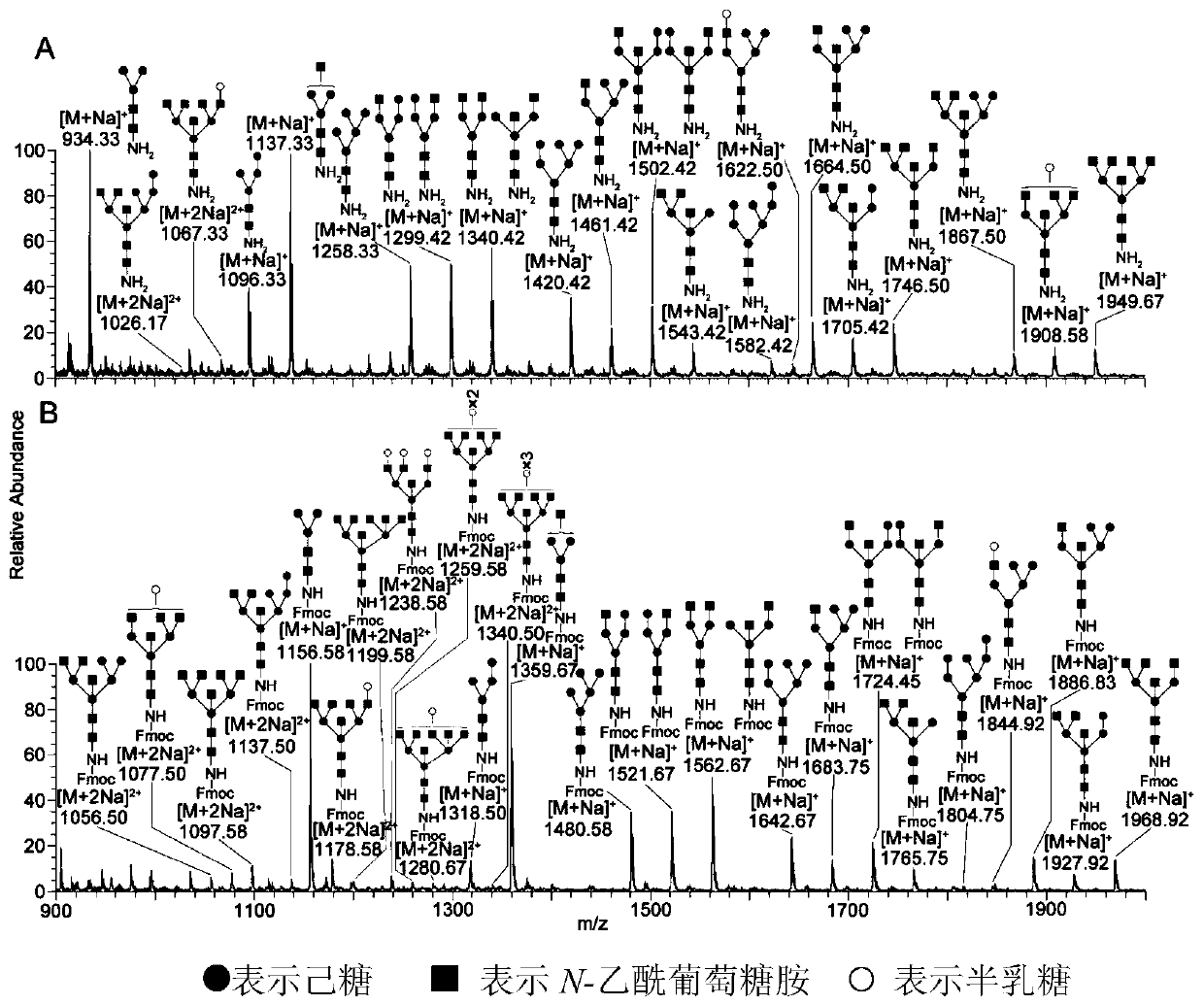

[0123] Example 1: Release and purification of egg albumin N-sugar chains by reducing chemical method

[0124] Chemical release:

[0125] Weigh 10 mg of egg albumin, which is a neutral N-sugar chain, dissolve it in concentrated ammonia water (1 mL, concentration 26% to 28%); add NaOH solid to the reaction system until the concentration of NaOH in the reaction system is 0.3mol / L, add NaBH to the reaction system 3 CN solid to NaBH in the reaction system 3 The concentration of CN was 1mol / L; the obtained reaction mixture was reacted at 40°C for 16 hours. After the reaction, the reaction system was concentrated under reduced pressure with a rotary evaporator, and after redissolving with 1 mL of double distilled water, the pH was adjusted to neutral (pH 7 or so), again use a rotary evaporator to concentrate under reduced pressure to remove the solvent, and obtain the crude N-sugar chain of egg albumin. For neutral N-sugar chains, adding sodium hydroxide in the reaction system c...

Embodiment 2

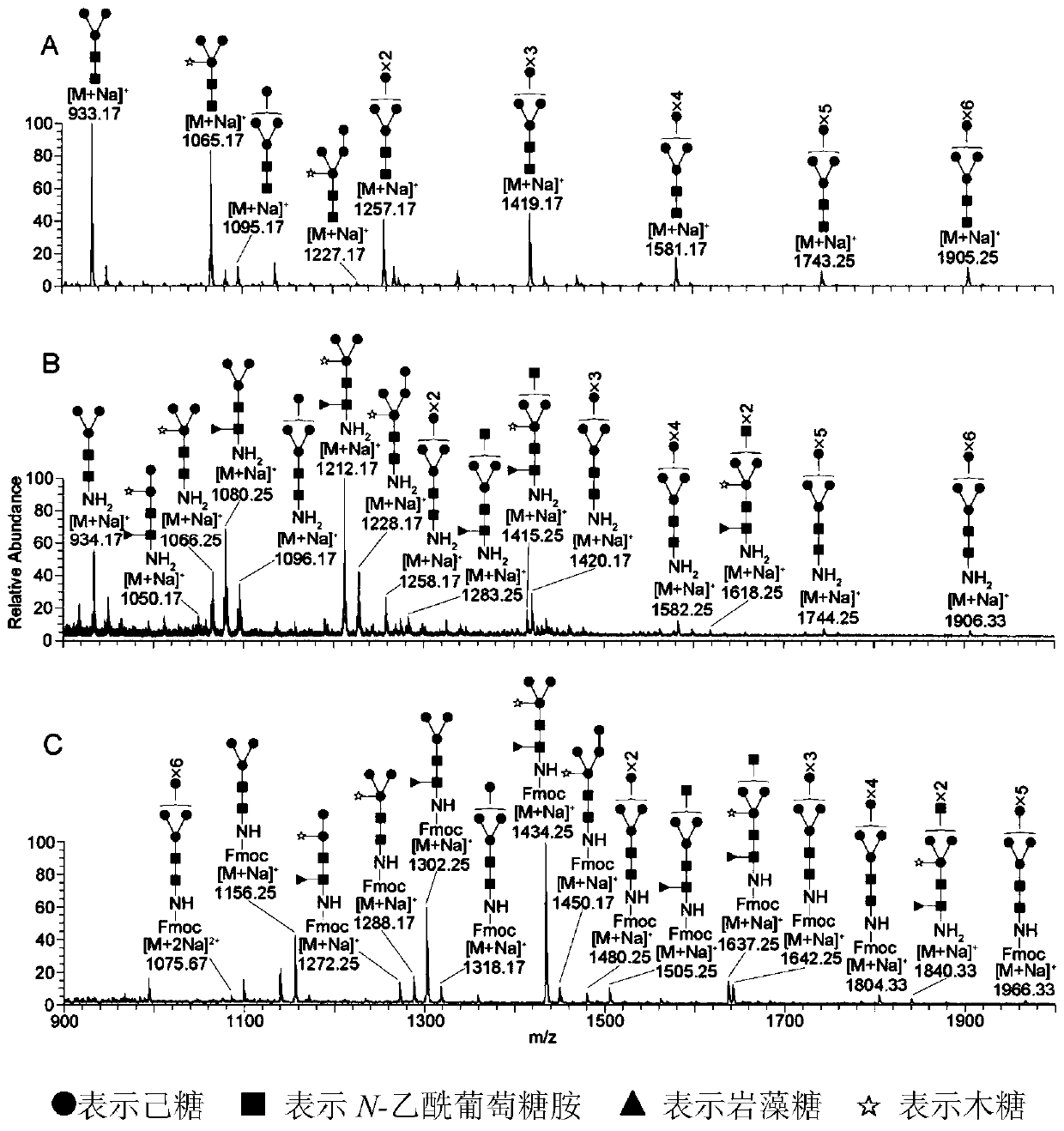

[0140] Example 2: Release and purification of buckwheat pollen total protein N-glycans by reducing chemical method

[0141] Chemical release:

[0142] Weigh 10 mg of buckwheat pollen total protein, which is a neutral N-sugar chain, dissolve it in concentrated ammonia water (1 mL, mass concentration 26% to 28%); add NaOH solid to the reaction system The concentration of NaOH in the medium is 0.3mol / L, add NaBH to the reaction system 3 CN solid to NaBH in the reaction system 3 The concentration of CN is 1mol / L. The obtained reaction mixture was reacted at 40°C for 16 hours. After the reaction was completed, the reaction system was concentrated under reduced pressure with a rotary evaporator, and 1 mL of double-distilled water was added to dissolve it again. Concentrate under reduced pressure with a rotary evaporator to remove the solvent to obtain the crude N-glycan chain of buckwheat pollen total protein.

[0143] The method for purifying the crude N-sugar chain of buckwh...

Embodiment 3

[0150] Example 3: Release and purification of fetal bovine serum total protein N-glycans by reducing chemical method

[0151] Chemical release:

[0152] Weigh 10 mg of fetal bovine serum total protein, the sugar chain of fetal bovine serum total protein is acidic N-sugar chain, dissolve in concentrated ammonia water (1mL, concentration 26%-28%); add NaBH to the reaction system 3 CN solid to NaBH in the reaction system 3 The concentration of CN is 1mol / L. The obtained reaction mixture was reacted at 40°C for 16 hours. After the reaction was completed, the reaction system was concentrated under reduced pressure with a rotary evaporator, and 1 mL of double-distilled water was added to dissolve it again. Concentrate under reduced pressure with a rotary evaporator to remove the solvent to obtain the crude product of N-sugar chains of fetal bovine serum total protein.

[0153] For acidic N-sugar chains, no sodium hydroxide is added to adjust the alkalinity to prevent deacetylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com