Virtual die matching method based on measurement

A technology of mold matching and measuring points, which is applied in the field of virtual mold matching based on measurement, can solve the problems of mold matching in measurement technology, and achieve the effects of improving mold matching efficiency, quantifying out-of-tolerance, and reducing manual steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

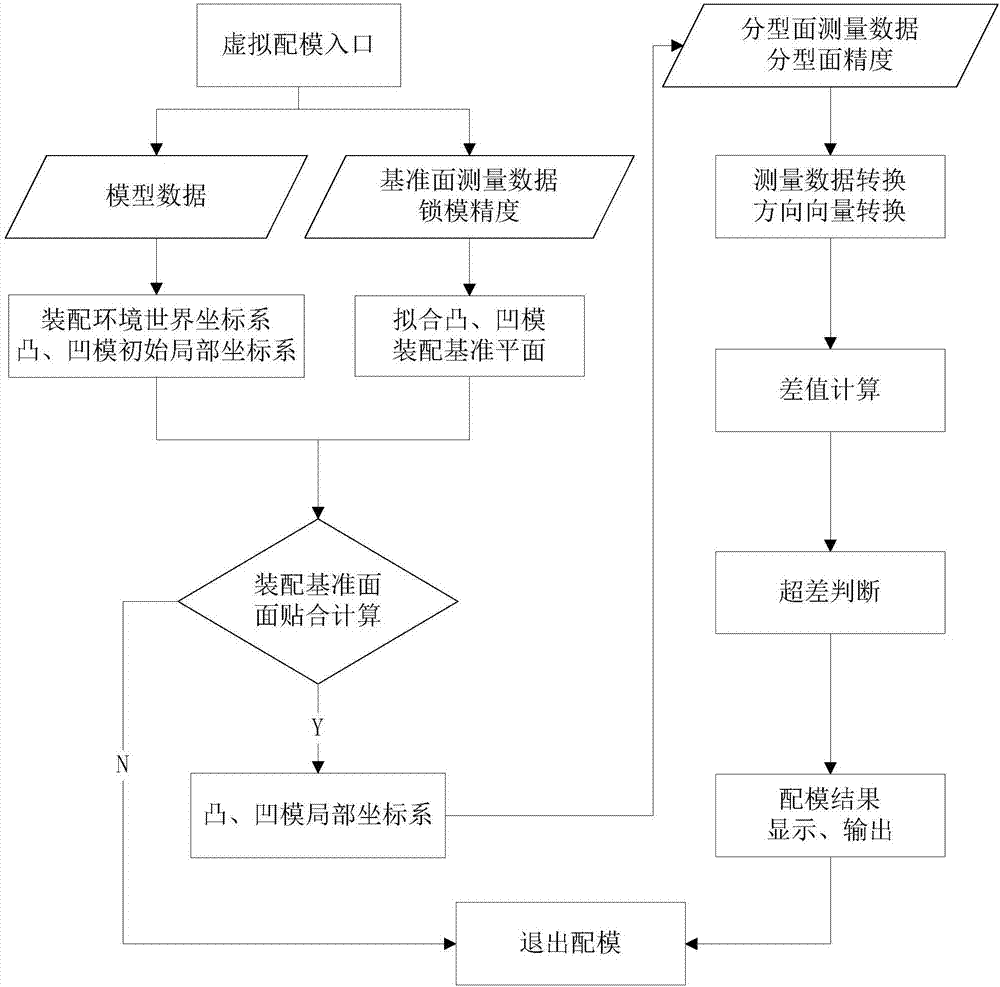

[0028] see figure 1 , the present invention is based on the virtual model matching method of measurement comprising the following steps:

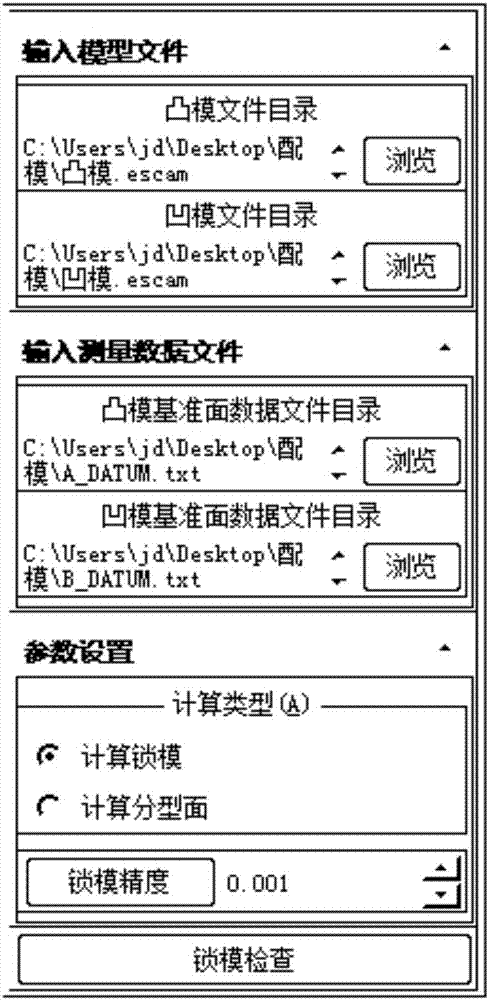

[0029] 1) see figure 2 , read in and analyze the model file, datum plane measurement data, and fit the assembly datum plane;

[0030] 1.1) Read in the model files of the punch and die, and obtain the world coordinate system LW and the initial local coordinate system LA of the punch in the assembly environment 0 , Die initial local coordinate system LB 0 ;

[0031] 1.2) Read in the reference plane measurement data file and the clamping accuracy Tol O , to check the correctness of the data;

[0032] 1.3) Fit the assembly datum plane according to the datum plane measurement data file.

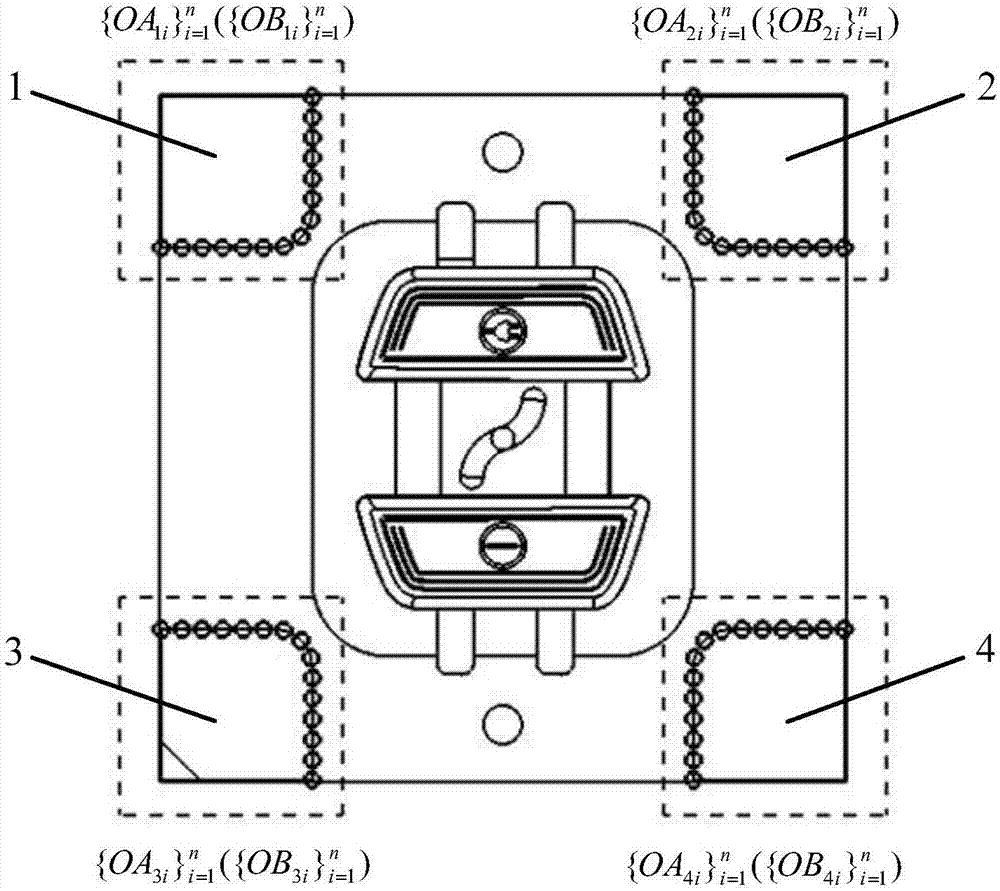

[0033] 1.3.1) see image 3 , record the measurement point set of the base plane of the punch as The measurement point set of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com