An intelligent cold chain logistics monitoring system and its application method

A cold chain logistics and monitoring system technology, applied in the field of logistics, can solve the problems of high material loss rate, irregular packaging, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Mainly introduce the basic composition of the intelligent cold chain logistics monitoring system of the present invention.

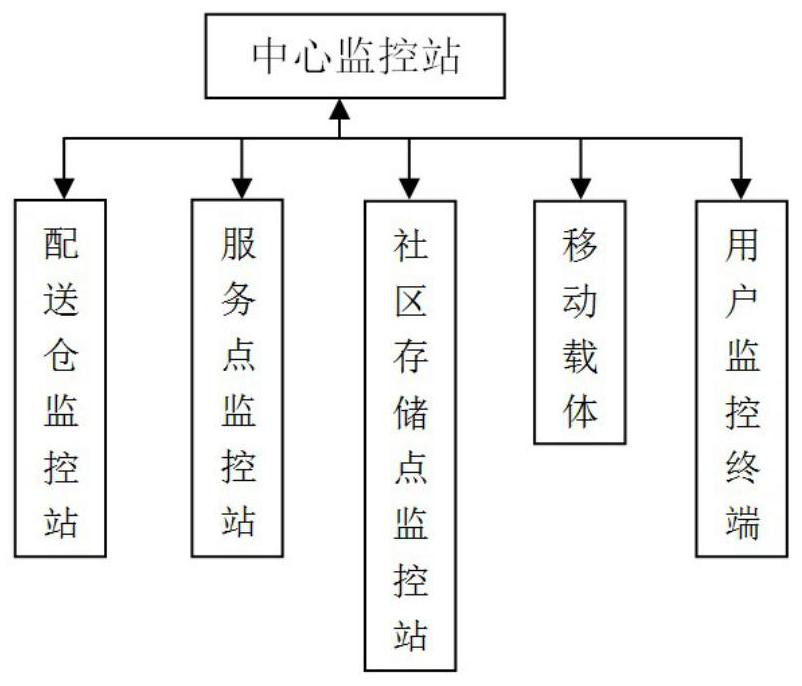

[0067] as attached figure 1 , an intelligent cold chain logistics monitoring system, which is a comprehensive monitoring system, at least including a central monitoring station, a distribution warehouse monitoring station, a service point monitoring station, a community storage point monitoring station, a mobile carrier, and a user monitoring terminal.

[0068] Each component of the monitoring system establishes communication through the Internet or a local area network.

[0069] The central monitoring station is responsible for the management and control of the entire cold chain logistics, and has a central server, a display, a processor, a communication module, an alarm, and a cloud storage. The memory includes pre-stored data, as well as real-time uploaded and exchanged data. The processor may be embedded in the central server.

[0070] The ...

Embodiment 2

[0080] This embodiment is carried out on the basis of the foregoing embodiment 1, and mainly introduces the basic usage method of the intelligent cold chain logistics monitoring system of the present invention.

[0081] The usage method of the monitoring system is as follows:

[0082] 1. The distribution warehouse monitoring station receives the instructions from the central monitoring station, extracts the order information, and the staff prepares the corresponding products for the order; each product or package has a unique identification code, and the identification code contains at least the following information: product number, user information , distribution warehouse information, product category information.

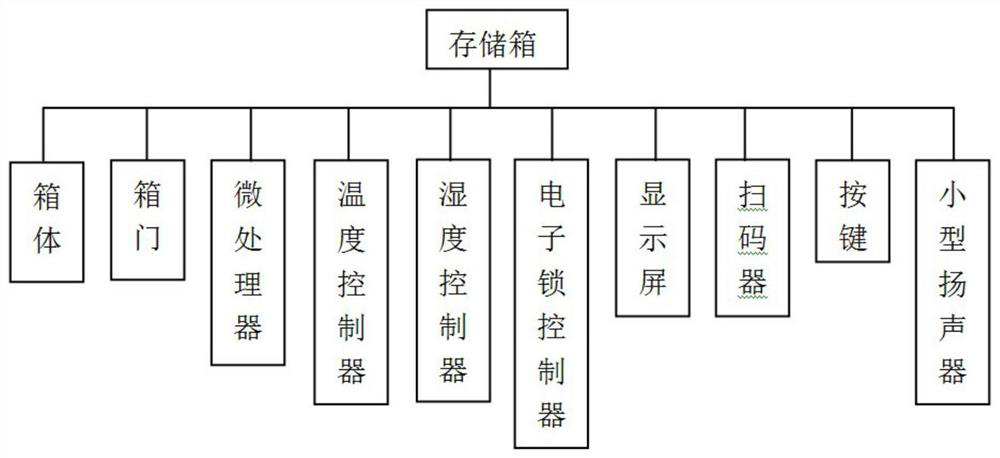

[0083] 2. When the product or package with the identification code is entered into the mobile carrier and stored in the storage device, the identification code is scanned, and the information of the identification code is extracted by the storage device and disp...

Embodiment 3

[0094] This embodiment is carried out on the basis of the foregoing embodiment 1 or 2, and mainly introduces the data collection method of the mobile carrier of the present invention.

[0095] The data collection of described mobile carrier, comprises the steps as follows:

[0096] 1. Before departure, create an initial task database, including manual input data, and the above data is assigned to the identification code;

[0097] 2. After departure, the processor on the mobile carrier sends instructions to the data collector device and the locator through the communication module. The instruction information includes the collection time interval of various data collectors. After the data collector and locator collect data, they pass the data The transceiver transmits the data to the processor, and the processor feeds the data back to the central monitoring station through the communication module.

[0098] 3. The processor can compare the collected data with the storage conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com