A cold shock reactor

A reactor, cold-shock technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc. Problems such as large pressure drop, to achieve the effect of uniform bed temperature, lower bed temperature, and lower bed lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

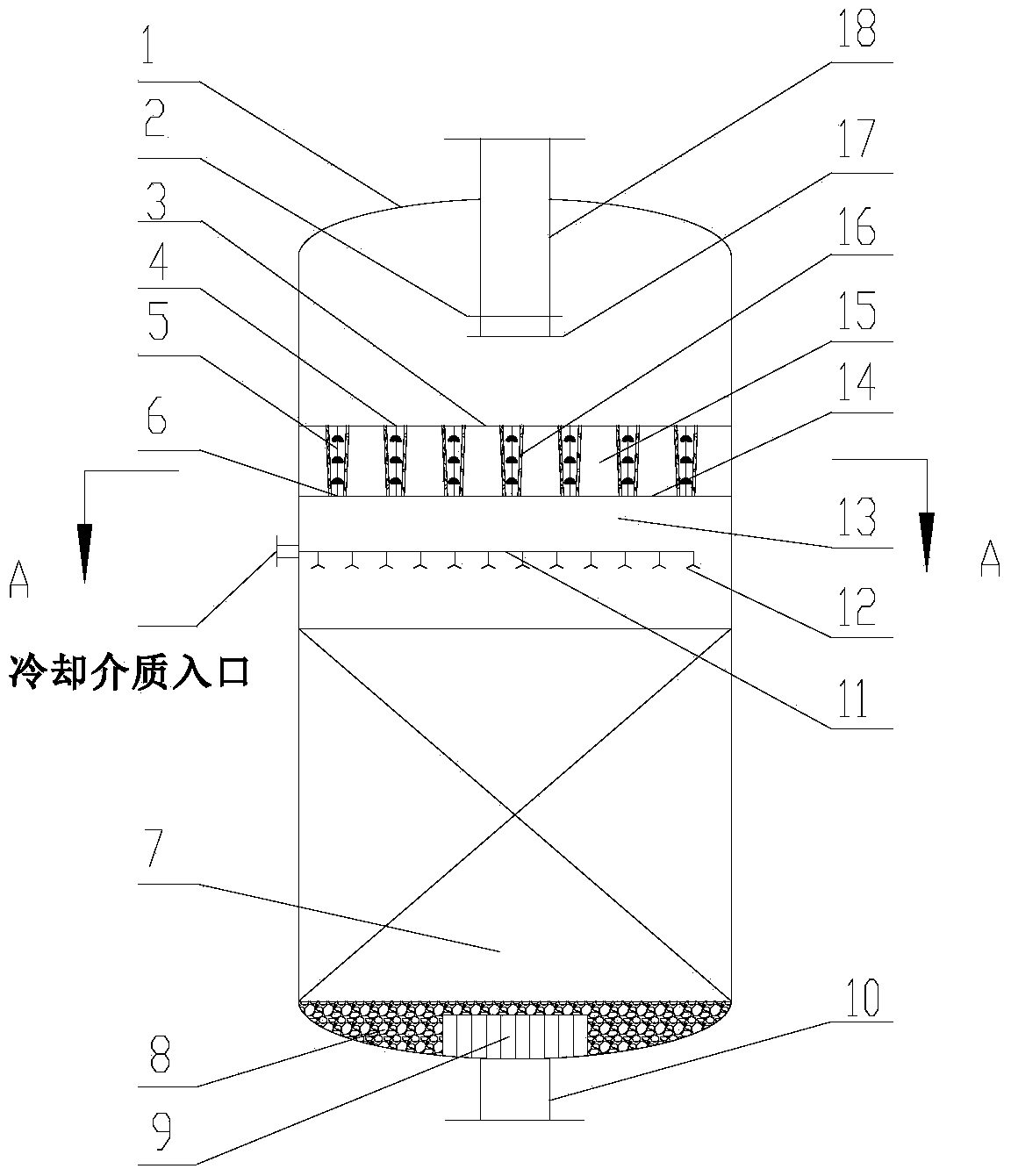

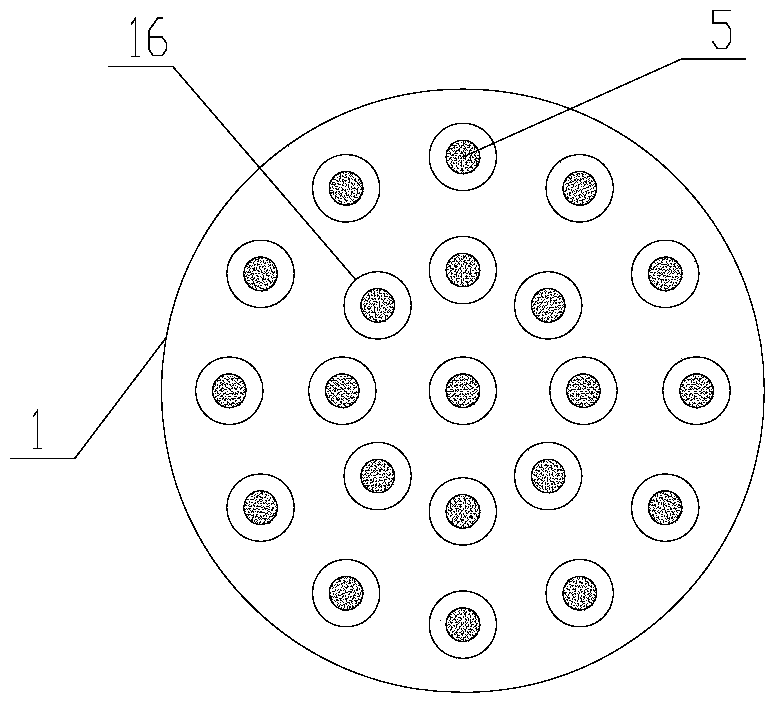

[0068] Such as figure 1As shown, the chilled shock reactor adopted in this embodiment includes a pressure-bearing shell 1 with an inlet pipe 18 at the upper end and an outlet pipe 10 at the lower end. The first gas distributor 2 is provided at the bottom of the inlet pipe 18, and A second gas distributor 17 is arranged below the first gas distributor 2 . The bottom of the inlet pipe 18 has an axial microchannel reaction zone 21 and an axial catalytic reaction zone 7, and the axial microchannel reaction zone 21 is positioned directly above the axial catalytic reaction zone 7, and the axial microchannel reaction zone 21 includes an axial Microchannel reaction unit 15. Axial micro-channel reaction unit 15 is a container that can accommodate micro-reaction channels 16 coaxial with cylindrical housing 1, and includes bottom sealing plate 14, top sealing plate 3 and side walls, and its side walls are in line with the sides of housing 1. The walls are sealed and connected, and the ...

Embodiment 2

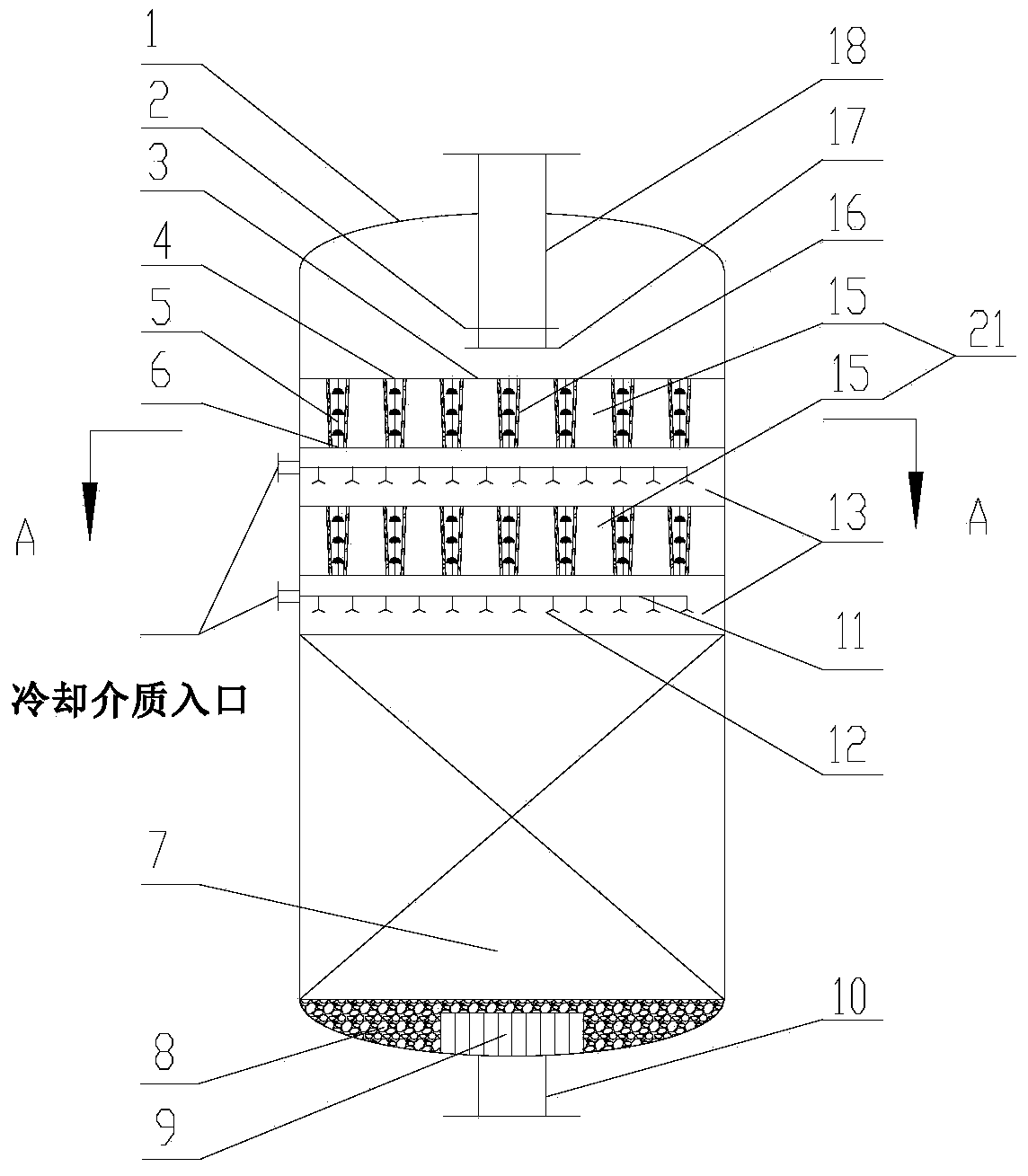

[0075] Such as figure 2 , image 3 As shown, the reactor in this embodiment has the same structure parameters as the reactor in embodiment 1, such as the inner diameter of the shell, the height of the axial catalytic reaction zone and the height of the axial microchannel reaction unit. The difference from Embodiment 1 is that there are two axial microchannel reaction units 15 in this embodiment, and a cooling medium distributor 11 is also arranged in the gap between the two axial microchannel reaction units 15 .

[0076] The reactor proposed by the present invention is applied to the methanation reaction of syngas, and the amount of active metal Ni loaded in the conical tube is 21.6g / m 2 . The synthesis gas enters the reactor from the inlet pipe, and after axially passing through the two columns, the methanation reaction continues in the axial catalytic reaction zone, and the reaction product leaves the reactor through the outlet pipe at the bottom of the reactor.

[0077]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com