Polyamic Acid Composition, Polyamideimide Film Thereof and Method for Preparing Polyamideimide Film

A technology of polyamide-imide film and polyamic acid is applied in the field of preparing the polyamide-imide film, and can solve the problems of reduced transmittance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation of oligomeric amic acid solution in the step (a) is to add organic solvent in the reactor, and 2,2'-bis (trifluoromethyl) benzidine is dissolved in the reactor, subsequently with cycloaliphatic di The step of anhydride reaction, wherein it is preferable to add the monomer to the organic solvent in a stepwise manner, rather than adding the monomer to the organic solvent at one time, because the reactivity can be improved. Moreover, first, it is more preferable to fully dissolve 2,2'-bis(trifluoromethyl)benzidine in an organic solvent.

[0055] The organic solvent is the same as above, and is preferably dimethylacetamide or N-methyl-2-pyrrolidone. In addition, there is no great limitation on the content of the organic solvent, which may be appropriately selected in consideration of the molecular weight of the polyamideimide resin obtained by copolymerization, and may be 70-95% by weight of the total composition. Preferably, the content of the organic solv...

Embodiment 1

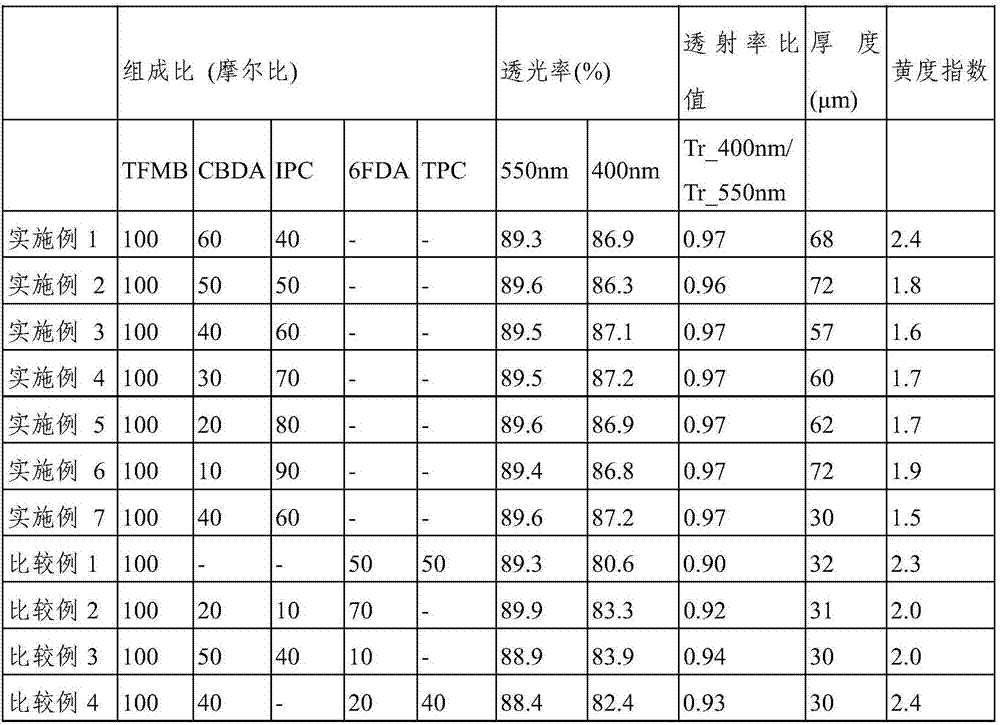

[0096] Embodiment 1[TFMB:CBDA:The molar ratio of IPC=100:60:40]

[0097] Under a nitrogen atmosphere, N,N-dimethylacetamide (DMAc) and 2,2'-bis(trifluoromethyl)benzidine (TFMB) were added to the reactor, and the mixture was stirred well. Then, cyclobutanetetracarboxylic dianhydride (CBDA) was added thereto, and stirred sufficiently until dissolved. Then, isophthaloyl chloride (IPC) was added thereto, and stirred for 6 hours, and then dissolved and reacted, thereby preparing a polyamic acid composition. Here, the content of each monomer was the same as the composition ratio in Table 1 below, and the temperature of the reactor was kept at 30°C. The viscosity of the prepared polyamic acid composition was 90,000 cps. Next, pyridine and acetic anhydride were added to the solution at a content of 2.5 times the content of cyclobutanetetracarboxylic dianhydride (CBDA), and stirred at 60° C. for 1 hour.

[0098] Then, the solution was precipitated with excess methanol, and the resul...

Embodiment 2

[0100] Embodiment 2[TFMB:CBDA:The molar ratio of IPC=100:50:50]

[0101] Under a nitrogen atmosphere, N,N-dimethylacetamide (DMAc) and 2,2'-bis(trifluoromethyl)benzidine (TFMB) were added to the reactor, and the mixture was stirred well. Then, cyclobutanetetracarboxylic dianhydride (CBDA) was added thereto, and stirred sufficiently until dissolved. Then, isophthaloyl chloride (IPC) was added thereto, and stirred for 6 hours, and then dissolved and reacted, thereby preparing a polyamic acid composition. Here, the content of each monomer was the same as the composition ratio in Table 1 below, and the temperature of the reactor was kept at 30°C. The viscosity of the prepared polyamic acid composition was 77,000 cps. Next, pyridine and acetic anhydride were added to the solution at a content of 2.5 times the content of cyclobutanetetracarboxylic dianhydride (CBDA), and stirred at 60° C. for 1 hour.

[0102] Then, the solution was precipitated with excess methanol, and the resul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com