Epitaxial equipment maintenance method

An equipment maintenance and epitaxy technology, applied in chemical instruments and methods, from chemical reactive gases, crystal growth, etc., can solve problems such as parts loss, and achieve the effect of extending maintenance cycles, improving equipment capacity utilization, and reducing production costs.

Inactive Publication Date: 2017-11-28

SHANGHAI JINGMENG SILICON CORP

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] This is because during the epitaxial growth process, in addition to growing single crystal epitaxy on the substrate single crystal silicon wafer, a polysilicon layer will also grow on the surface in other areas of the reaction chamber, and this polysilicon layer will cause particles in the reaction chamber, Abnormal temperature changes, hydrogen chloride can etch away the polysilicon layer covering the inner surface of the reaction chamber, but it also causes the loss of main parts in the chamber

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 Embodiment 3

[0034] The data of each part of Embodiment 1 to Embodiment 3 are shown in Table 1.

[0035] Table 1:

[0036]

[0037] Wherein, in the third embodiment, since the etching time is less than 20 seconds, the minimum value of 20 seconds is used for calculation.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

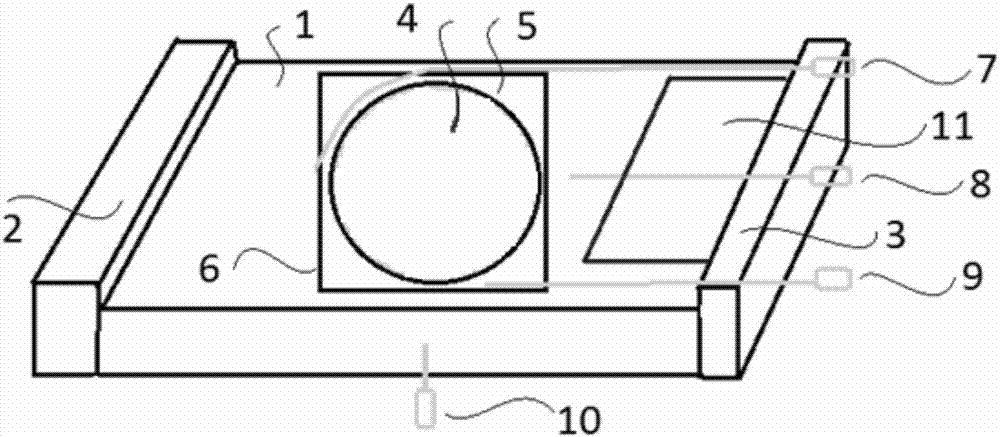

The invention provides an epitaxial equipment maintenance method. The epitaxial equipment comprises a reaction cavity, wherein the reaction cavity is provided with an air inlet and an air outlet; a base is arranged in the reaction cavity and is used for carrying a silicon chip; a heat absorption device is also arranged in the reaction cavity, is positioned between the base and the air outlet, and is positioned at the upper half part of the reaction cavity. The epitaxial equipment maintenance method comprises an etching step for removing a polycrystalline silicon layer deposited in the reaction cavity; etching gas of hydrogen chloride and carrier gas of hydrogen gas need to be introduced into the reaction cavity, wherein the etching temperature is 1165 to 1175 DEG C. Compared with the prior art, the epitaxial equipment maintenance method provided by the invention has the advantages that the equipment maintenance period can be effectively prolonged; the maintenance period is improved to a value greater than 60000 micrometers / time; the equipment capacity utilization rate is improved; the production cost is reduced.

Description

technical field [0001] The invention relates to a method for maintaining epitaxy equipment. Background technique [0002] The epitaxy equipment uses the reduction reaction of trichloromonohydrogen silicon or dichloro dihydrogen silicon with hydrogen to grow single crystal epitaxy on a single crystal substrate silicon wafer. With the increase in the number of epitaxial wafers produced, the reaction chamber of the equipment needs to be shut down Clean and maintain, and replace the main parts in the reaction chamber that are lost due to the regular etching of hydrogen chloride, such as the base (including the base ring), thermocouples, etc. [0003] This is because during the epitaxial growth process, in addition to growing single crystal epitaxy on the substrate single crystal silicon wafer, a polysilicon layer will also grow on the surface in other areas of the reaction chamber, and this polysilicon layer will cause particles in the reaction chamber, Abnormal temperature cha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C30B25/08C30B25/12C30B25/10C30B29/06

CPCC30B25/08C30B25/10C30B25/12C30B29/06

Inventor 陈海波

Owner SHANGHAI JINGMENG SILICON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com