Preparation method of lutein microcapsules and lutein microcapsule instant beverage

A technology of lutein and microcapsules is applied in the food field to achieve the effects of enhancing intestinal peristalsis, high safety and preventing age-related macular degeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

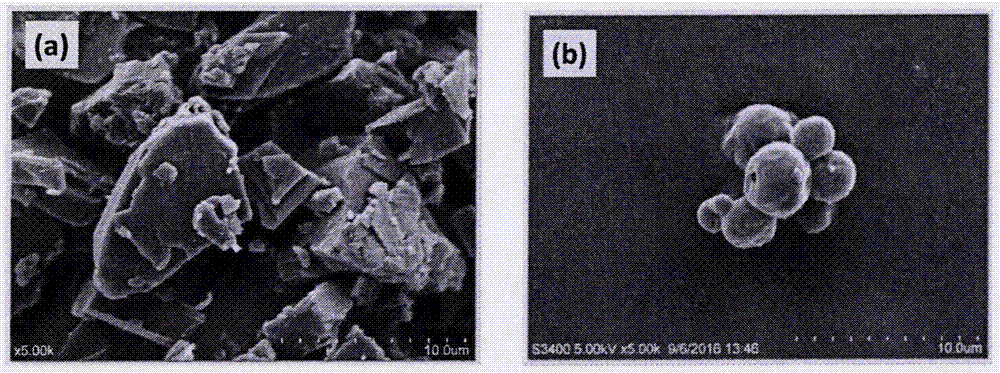

[0044] (1) Preparation of lutein core-wall material mixture: 4 g of natural lutein (core material) and 32 g of sodium caseinate (wall material) were weighed and dissolved in 200 mL and 600 mL of 40% edible alcohol respectively. Heat the completely dissolved sodium caseinate alcohol solution at 60°C for 5 minutes, then add the lutein alcohol solution dropwise to the sodium caseinate alcohol solution on a magnetic stirrer, and keep stirring for 10 minutes to obtain the lutein core-wall material mixture. Filter the obtained lutein core-wall material mixture with a 100-mesh sieve to remove large insoluble particles.

[0045] (2) High-speed dispersion: the filtered mixed solution was dispersed at a high speed of 10,000 rpm for 4 minutes, rested for 15 seconds every 30 seconds, and dispersed 8 times to obtain a lutein-sodium caseinate microemulsion with uniform texture;

[0046] (3) Spray drying: The obtained lutein-sodium caseinate microemulsion was spray-dried at an inlet tempera...

Embodiment 2

[0048] (1) Preparation of lutein core-wall material mixture: 4g of natural lutein and 48g of sodium caseinate were weighed and dissolved in 200mL and 600mL of 40% edible alcohol respectively. Heat the completely dissolved sodium caseinate alcohol solution at 60°C for 5 minutes, then add the lutein alcohol solution dropwise to the sodium caseinate alcohol solution on a magnetic stirrer, and keep stirring for 140 minutes to obtain the lutein core-wall material mixture. Filter the obtained lutein core-wall material mixture with a 100-mesh sieve to remove large insoluble particles.

[0049] Step (2) is the same as in Example 1.

[0050] (3) Spray drying: The obtained lutein-sodium caseinate microemulsion is spray-dried at an inlet temperature of 200° C. and an outlet temperature of 90° C. to obtain dry lutein microcapsules.

Embodiment 3

[0052] (1) Preparation of lutein core-wall material mixture: 4 g of natural lutein and 4 g of sodium caseinate were weighed and dissolved in 200 mL and 600 mL of 40% edible alcohol respectively. Heat the completely dissolved sodium caseinate alcohol solution at 60°C for 5 minutes, then add the lutein alcohol solution dropwise to the sodium caseinate alcohol solution on a magnetic stirrer, and keep stirring for 125 minutes to obtain the lutein core-wall material mixture. Filter the obtained lutein core-wall material mixture with a 100-mesh sieve to remove large insoluble particles.

[0053] Step (2) is the same as in Example 1.

[0054] (3) Spray drying: The obtained lutein-sodium caseinate microemulsion was spray-dried at an inlet temperature of 185° C. and an outlet temperature of 90° C. to obtain dry lutein microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com