Environment-friendly separating and recovering device and method of sulfur hexafluoride/nitrogen mixed gas

A mixed gas, sulfur hexafluoride technology, applied in separation methods, perfluorocarbon/hydrofluorocarbon capture, chemical instruments and methods, etc., can solve the problem of separation and recovery effects affecting the generation and operation cost of power equipment, environmental impact , affecting the environment and other issues, to achieve good promotion prospects and use value, low installation cost, and the effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

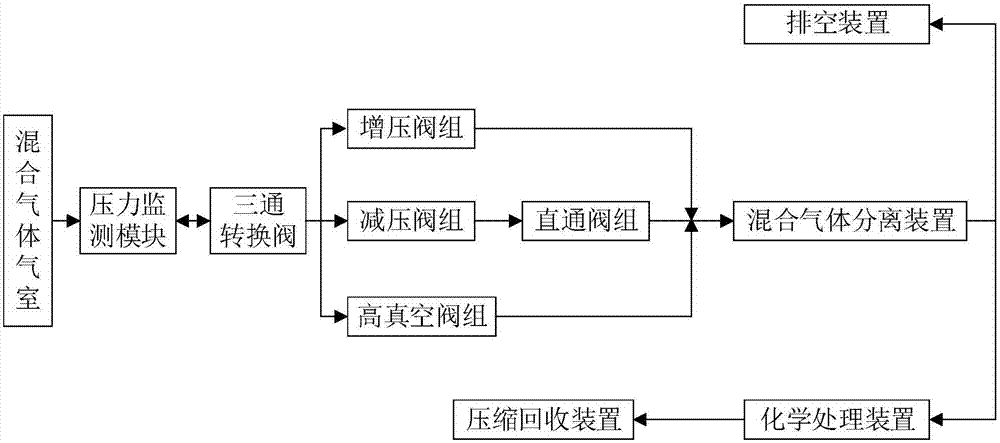

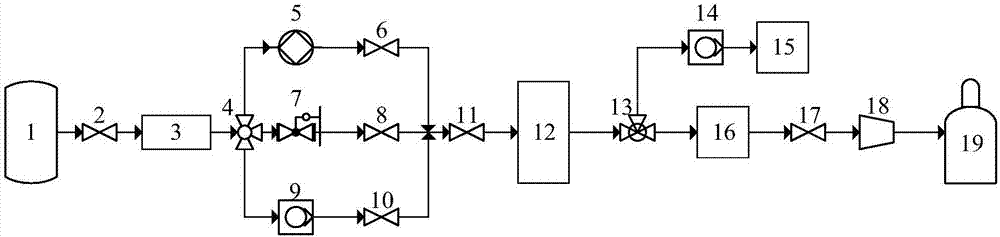

[0023] see figure 1 As shown, an environment-friendly sulfur hexafluoride / nitrogen mixed gas separation and recovery device of the present invention includes a pressure monitoring module, a three-way conversion valve, a straight-through valve group, a booster valve group, a high vacuum valve group, a mixed gas separation device, Evacuation units, chemical treatment units and compression recovery units.

[0024] The mixed gas chamber is connected to the inlet of the three-way switching valve through the pressure monitoring module, the first outlet of the three-way switching valve is connected to the inlet of the mixed gas separation device through the booster valve group, and the second outlet of the three-way switching valve is connected to the through-way valve group The inlet of the mixed gas separation device and the third outlet of the three-way switching valve are connected to the inlet of the mixed gas separation device through the high vacuum valve group; the outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com