Method for producing carburant by using graphitization furnace

A technology of graphitization furnace and production method, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of high sulfur content, achieve the effects of improving economic benefits, avoiding environmental pollution, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

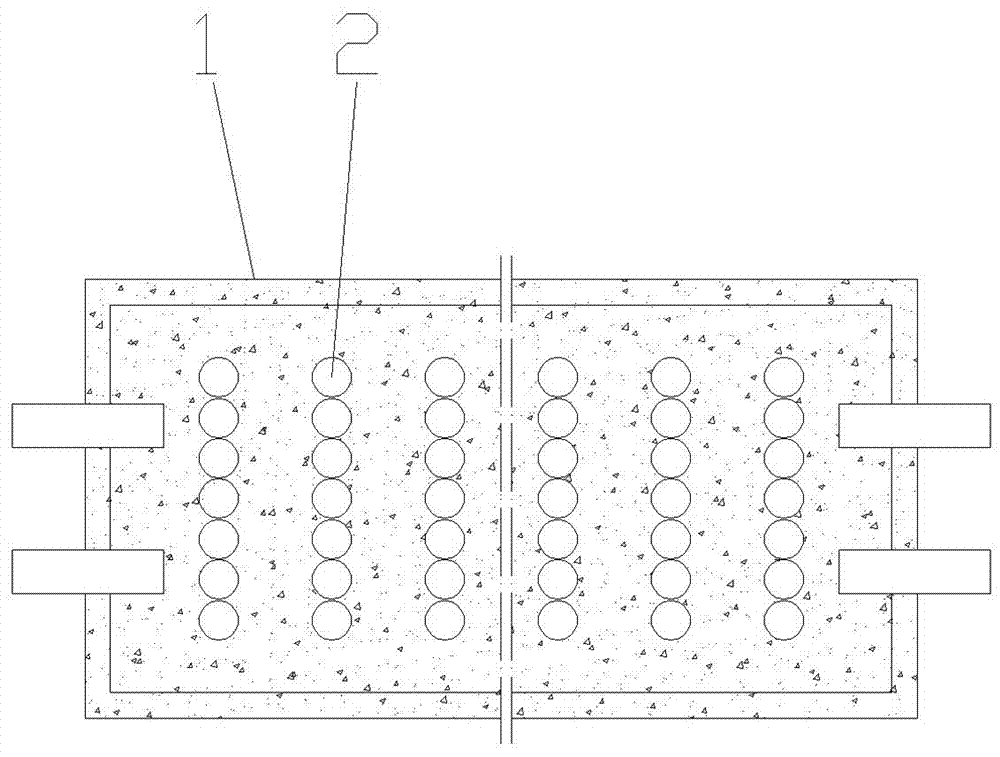

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0012] see figure 1 , a production method utilizing graphitization furnace 1 to produce recarburizer, the production steps are:

[0013] S1: placing the cylindrical crucible 2 equipped with the negative electrode material equidistantly in the graphitization furnace 1;

[0014] S2: Fill the gap between the crucibles 2 with anthracite powder, and at the same time add the anthracite powder as a resistance material to the surrounding furnace wall of the graphitization furnace 1 and the upper and lower ends of the graphitization furnace 1, and the added anthracite powder needs to be divided into three parts first. One part of anthracite powder is sent to the roller crusher to be crushed into particles of 1-5 mm; the second part of anthracite powder is sent to the jaw crusher to be crushed into particles of 5-12 mm; the third part of anthracite powder Grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com