Decoration board containing diatomite and production method of decoration board

A technology of decorative boards and diatomite, which is applied in the field of environmentally friendly decorative boards containing diatomite and its preparation, can solve problems such as human hazards, achieve low prices, remove air odors, and adjust air humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

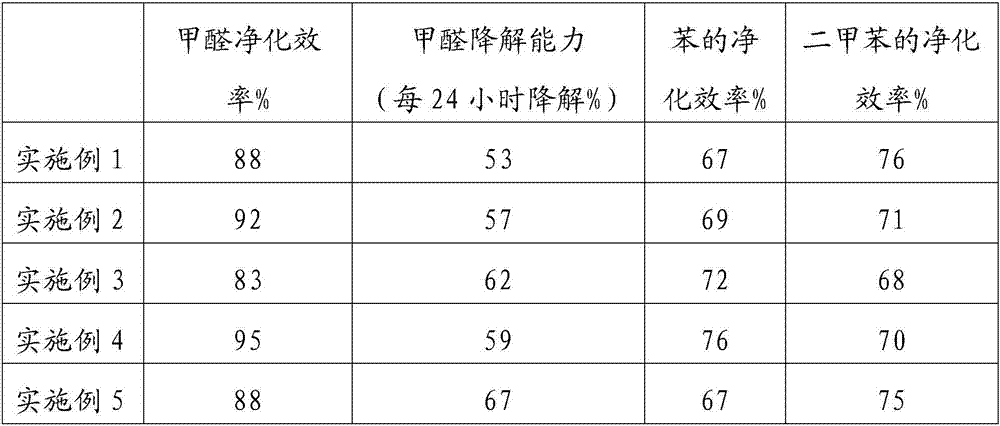

Examples

Embodiment 1

[0086] A preparation method of a decorative plate containing diatomite, comprising the following steps:

[0087] Step 1: In terms of parts by weight of raw materials, the following raw materials are taken:

[0088] 100 parts of diatomite, 25 parts of kaolin, 50 parts of titanium dioxide, 90 parts of shell powder, 120 parts of corn straw powder, 40 parts of polyvinyl chloride, 30 parts of glass fiber, 20 parts of HL-100 foam regulator, 15 parts of stearic acid part and 50 parts of water;

[0089] Step 2: Diatomaceous earth, shell powder, titanium dioxide, corn stalk powder, polyvinyl chloride, glass fiber, foam regulator, stearic acid and water are mixed and then added to a blender for stirring, first stirring at a low speed for 30 minutes at 800 rpm Minutes, then high-speed stirring for 30 minutes, rotating speed 4000 / min, mixed slurry A;

[0090] Step 3: Add the mixture A into the extruder and heat for 60 minutes at a temperature of 60°C to obtain the mixed slurry B;

[00...

Embodiment 2

[0095] A preparation method of a decorative plate containing diatomite, comprising the following steps:

[0096] Step 1: In terms of parts by weight of raw materials, the following raw materials are taken:

[0097] 110 parts of diatomite, 20 parts of kaolin, 45 parts of titanium dioxide, 80 parts of shell powder, 110 parts of corn straw powder, 50 parts of polyvinyl chloride, 25 parts of glass fiber, 18 parts of HL-100 foam regulator, 13 parts of stearic acid 60 parts of water and 60 parts;

[0098] Step 2: Diatomaceous earth, shell powder, titanium dioxide, corn stalk powder, polyvinyl chloride, glass fiber, foam regulator, stearic acid and water are mixed and then added to a blender for stirring. First, stir at a low speed for 60 minutes at a speed of 800 rpm Minutes, then high-speed stirring for 60 minutes, rotating speed 4000 / min, mixed slurry A;

[0099] Step 3: Add the mixture A into the extruder and heat for 60 minutes at a temperature of 60°C to obtain the mixed slur...

Embodiment 3

[0104] A preparation method of a decorative plate containing diatomite, comprising the following steps:

[0105] Step 1: In terms of parts by weight of raw materials, the following raw materials are taken:

[0106] 120 parts of diatomite, 15 parts of kaolin, 40 parts of titanium dioxide, 70 parts of shell powder, 100 parts of corn straw powder, 60 parts of polyvinyl chloride, 20 parts of glass fiber, 15 parts of HL-100 foam regulator, 10 parts of stearic acid 70 parts of water and 70 parts;

[0107] Step 2: Diatomaceous earth, shell powder, titanium dioxide, corn stalk powder, polyvinyl chloride, glass fiber, foam regulator, stearic acid and water are mixed and then added to the blender for stirring, first stirring at low speed for 45 minutes at 800 rpm Minutes, then high-speed stirring for 45 minutes, rotating speed 4000 / min, mixed slurry A;

[0108] Step 3: Add mixture A into the extruder and heat for 45 minutes at a temperature of 70°C to obtain mixed slurry B;

[0109] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com