Preparation method of high cross-linking ultraviolet cured waterborne polyurethane

A technology of water-based polyurethane and ultraviolet light, which is applied in the field of coatings, can solve the problems of poor product performance and low UV curing reaction efficiency, and achieve the effects of excellent chemical resistance and mechanical properties, high molecular weight, and high crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

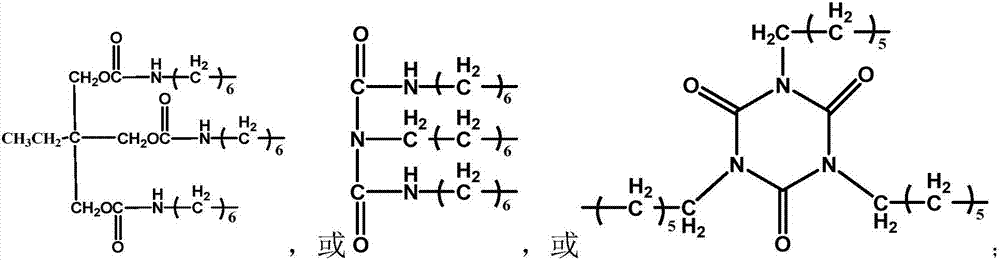

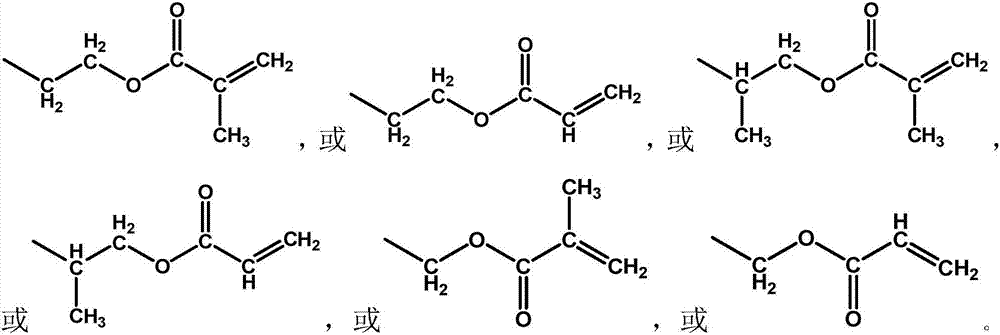

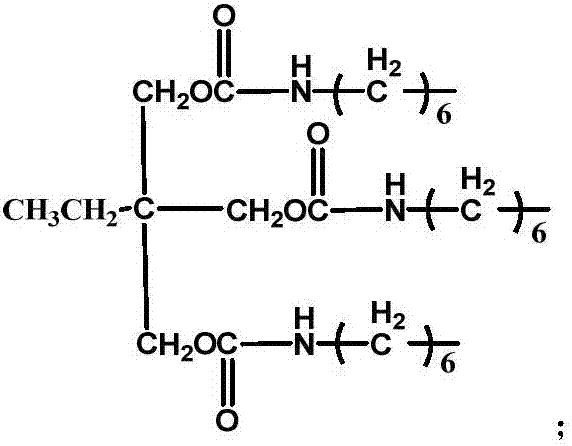

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of a highly cross-linked UV-curable waterborne polyurethane of the present embodiment comprises the following steps:

[0031] (1) 50 parts by weight of polyoxypropylene glycol, containing 35 parts by weight of double bond polyisocyanate and 55 parts by weight of toluene diisocyanate were reacted at 90-100 ° C for 3 hours;

[0032] (2) Add 20 parts by weight of 1,2-propanediol, 8 parts by weight of dimethylolpropionic acid, 30 parts by weight of acetone and 0.3 parts by weight of stannous octoate, and react at 60-80° C. for 6 hours;

[0033] (3) Add 100 parts by weight of acetone and 8 parts by weight of sodium ethylenediamine sulfonate, and react at 50-60°C for 0.5 hours;

[0034] (4) Add 80 parts by weight of acetone, add 8 parts by weight of triethylamine under high-speed shearing, add 450 parts by weight of water after stirring for 3 minutes, high-speed dispersion and emulsification for 3 minutes, and then add 8 parts by weight of isophorone di...

Embodiment 2

[0043] The preparation method of a highly cross-linked UV-curable waterborne polyurethane of the present embodiment comprises the following steps:

[0044] (1) 30 parts by weight of polyoxypropylene glycol, containing 50 parts by weight of double bond polyisocyanate and 10 parts by weight of toluene diisocyanate were reacted at 90-100 ° C for 4 hours;

[0045] (2) Add 5 parts by weight of 1,2-propanediol, 15 parts by weight of dimethylolpropionic acid, 10 parts by weight of acetone and 0.5 parts by weight of stannous octoate, and react at 60-80° C. for 4 hours;

[0046] (3) Add 50 parts by weight of acetone and 12 parts by weight of sodium ethylenediamine sulfonate, and react at 50-60°C for 0.5 hours;

[0047] (4) Add 50 parts by weight of acetone, add 12 parts by weight of triethylamine under high-speed shearing, add 600 parts by weight of water after stirring for 1 minute, high-speed dispersion and emulsification for 2 minutes, and then add 25 parts by weight of isophorone d...

Embodiment 3

[0056] The preparation method of a highly cross-linked UV-curable waterborne polyurethane of the present embodiment comprises the following steps:

[0057] (1) 80 parts by weight of polyoxypropylene glycol, containing 20 parts by weight of double bond polyisocyanate and 100 parts by weight of toluene diisocyanate were reacted at 90-100 ° C for 2 hours;

[0058] (2) Add 40 parts by weight of 1,2-propanediol, 3 parts by weight of dimethylol propionic acid, 50 parts by weight of acetone and 0.1 part by weight of stannous octoate, and react at 60-80° C. for 7 hours;

[0059] (3) Add 150 parts by weight of acetone and 5 parts by weight of sodium ethylenediamine sulfonate, and react at 50-60° C. for 1 hour;

[0060] (4) Add 100 parts by weight of acetone, add 2.5 parts by weight of triethylamine under high-speed shearing, add 300 parts by weight of water after stirring for 5 minutes, high-speed dispersion and emulsification for 5 minutes, and then add 15 parts by weight of isophoron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com