Device and method for detecting quality of liquid dairy products with near infrared transmittance technique

A near-infrared, dairy technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of weak absorption, low spectral signal-to-noise ratio, and complex spectra, and achieve cost-saving and non-destructive measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention will be described in detail as follows: rear.

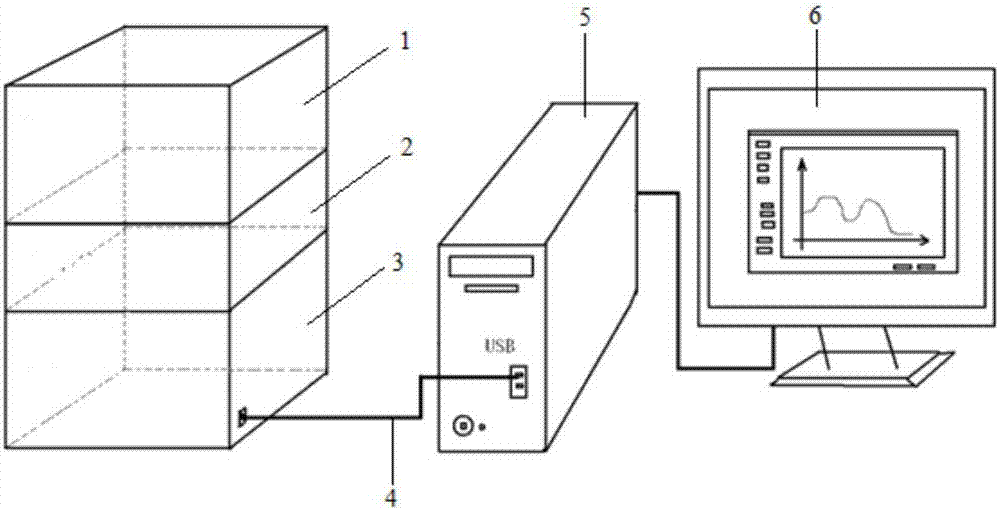

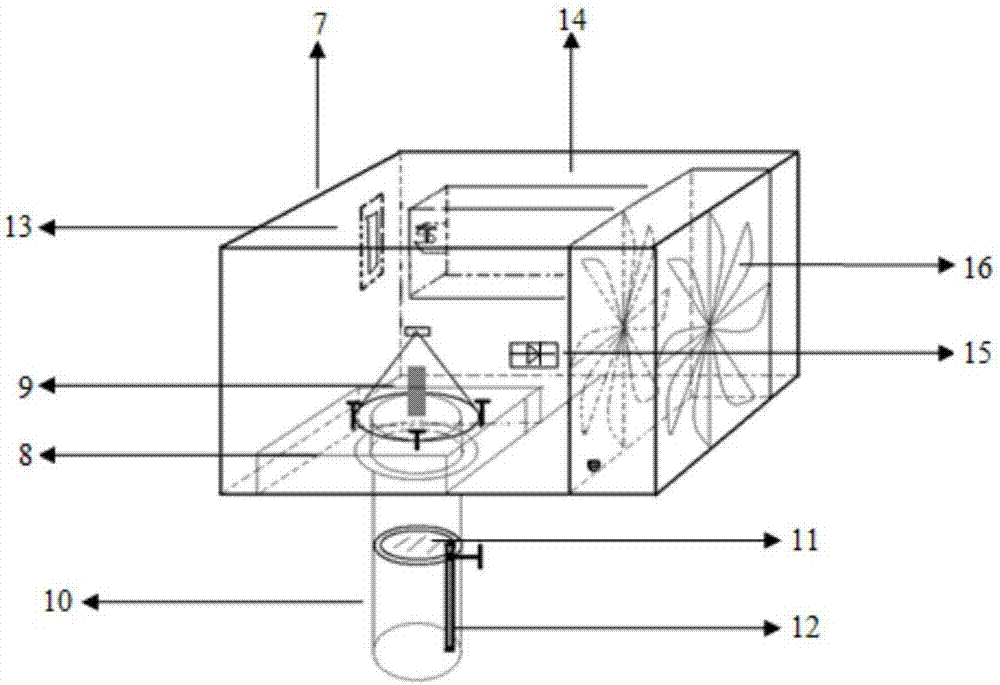

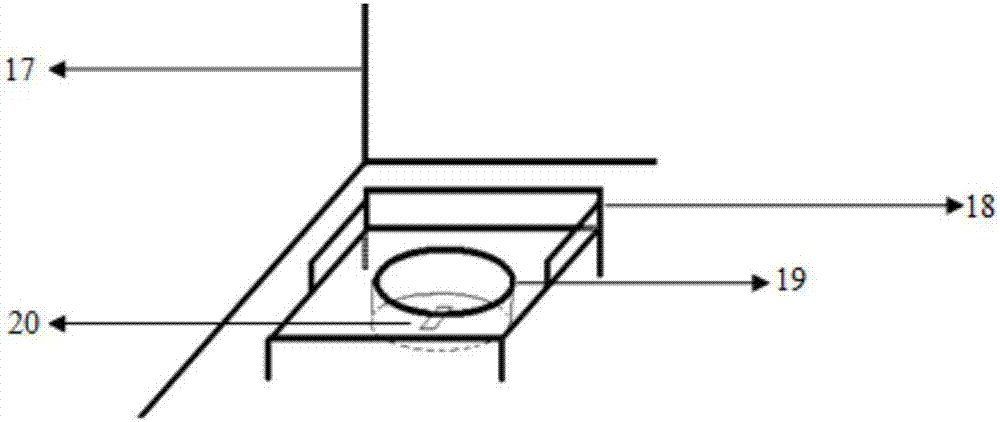

[0055] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a liquid dairy product quality detection device based on near-infrared transmission technology includes a light source system 1 (near-infrared short-wave band), a sample chamber 2, a spectroscopic system 3 (optical signal reception), a data transmission line 4, a computer 5 and Display 6 composition. The light source system includes a light source outdoor wall 7, a lamp bracket 8, an iodine tungsten lamp 9, a focusing lens barrel 10, a focusing lens 11, an adjustment slide bar 12, a switch 13, a transformer 14, a rectifier circuit 15 and a fan 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com