Raw silk or soaked silk appearance quality detection device and detection method based on binocular vision

A technology of binocular vision and appearance quality, applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems of being easily affected by environmental conditions, high cost, poor repeatability, etc. Dithering operation, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

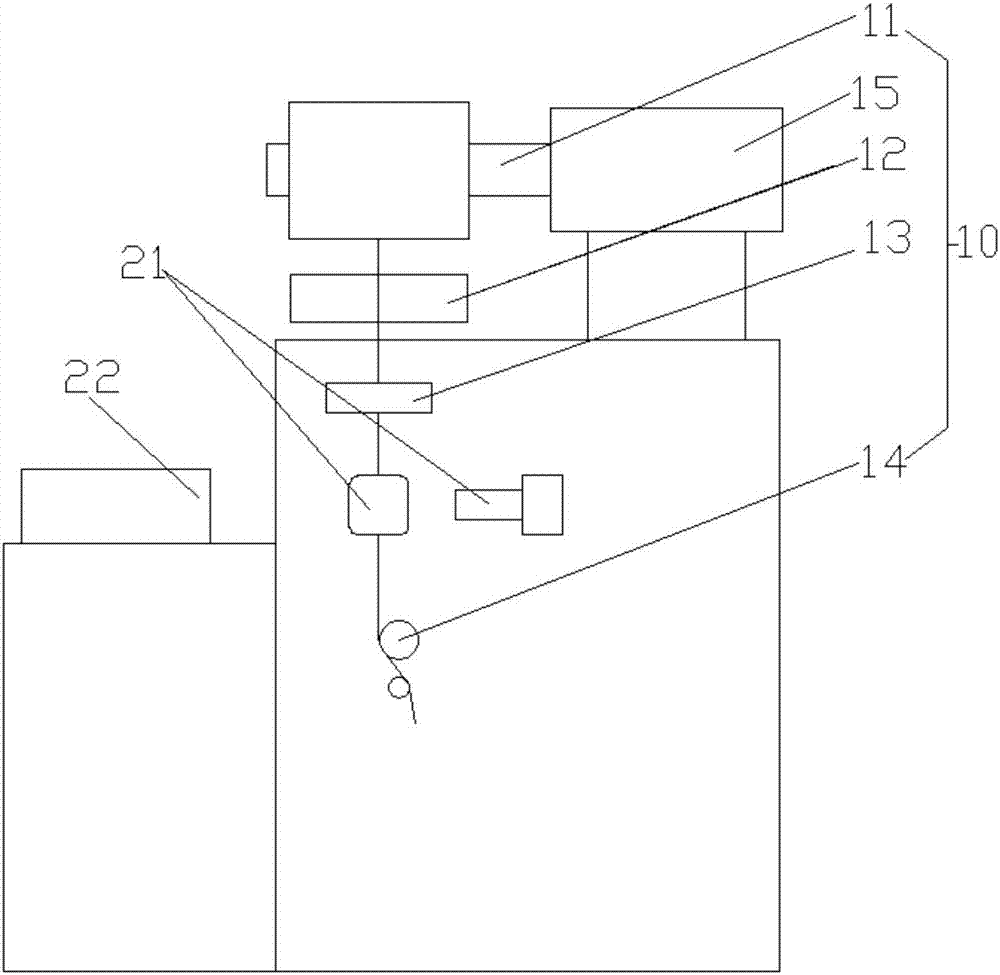

[0035] see Figure 1 to Figure 4 , as shown in the legend therein, a binocular vision-based inspection device for the appearance quality of raw silk or soaked silk, including:

[0036] Motion control system 10, which drives the raw silk or soaked silk to run along its vertical axis at 1-1200m / min;

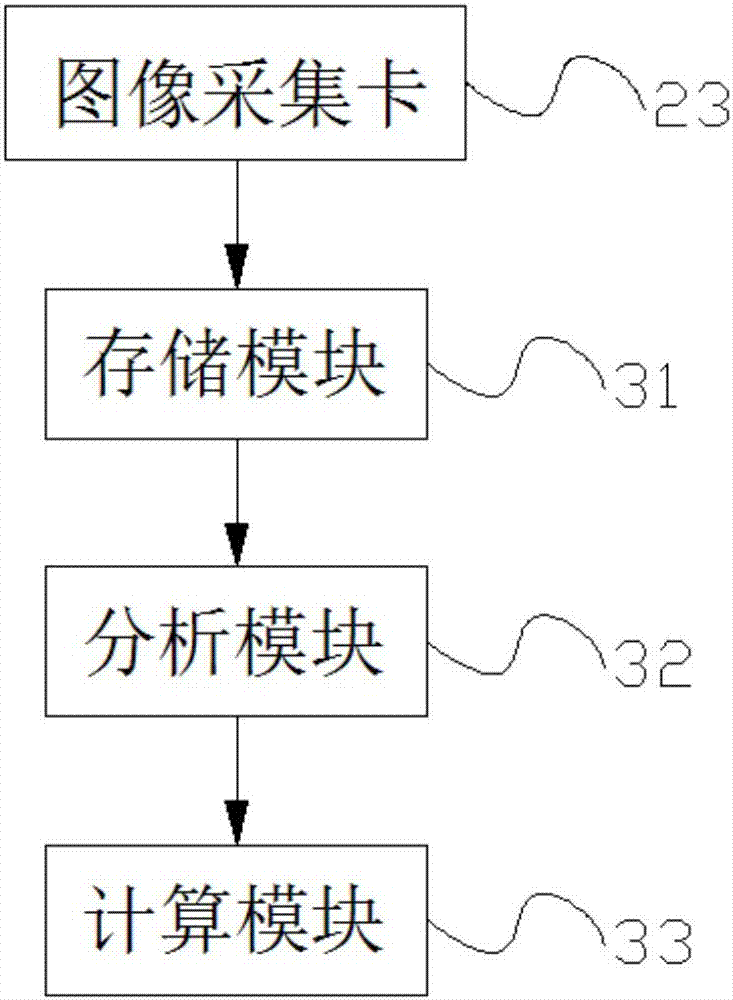

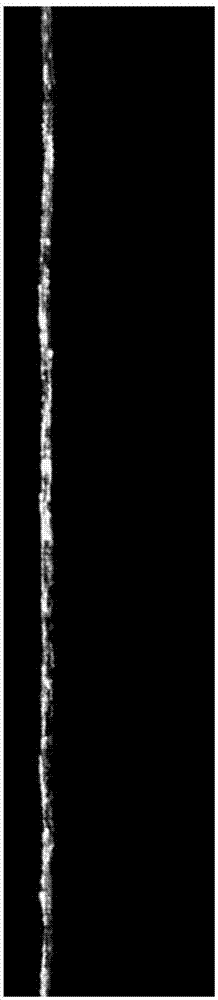

[0037] The image acquisition system includes two cameras 21, and the two cameras 21 are located on the same horizontal plane, and are respectively arranged on the first horizontal radial outer side and the second horizontal radial outer side of the running raw silk or soaked silk, and collect raw silk or soaked silk respectively. a first horizontal radial image and a second h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com