Synchronous nitrification and denitrification filter tank

A technology of denitrification filter and synchronous nitrification, which is applied in the field of synchronous nitrification and denitrification filter, can solve the problems of large occupied area and achieve the effects of small occupied area, good filtering environment and less sand run-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below by embodiment the content of the present invention is specified:

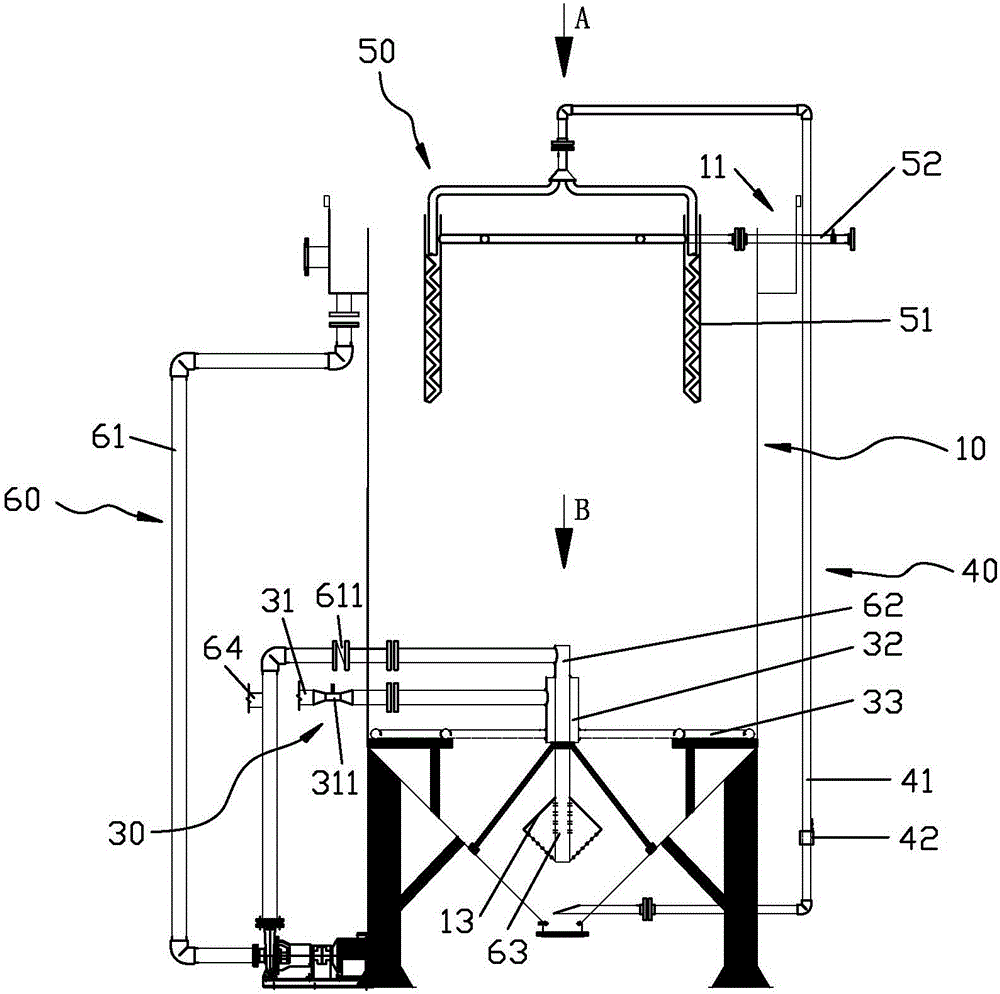

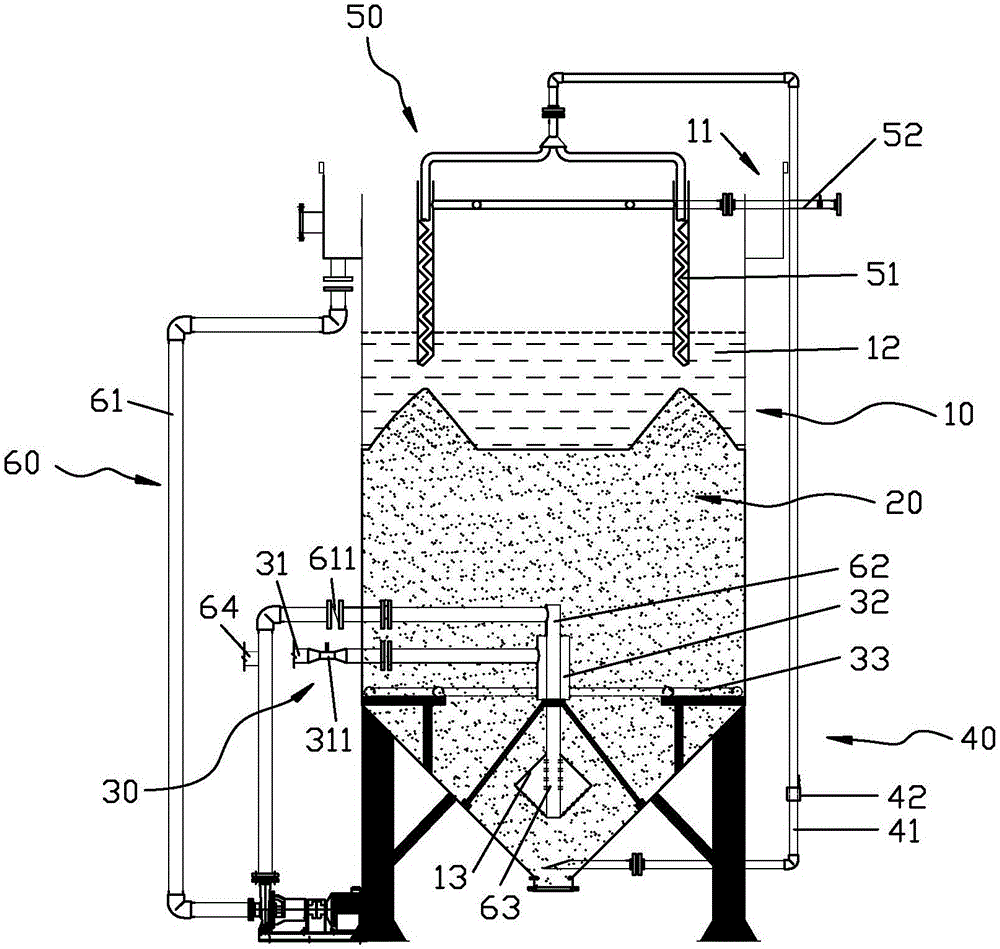

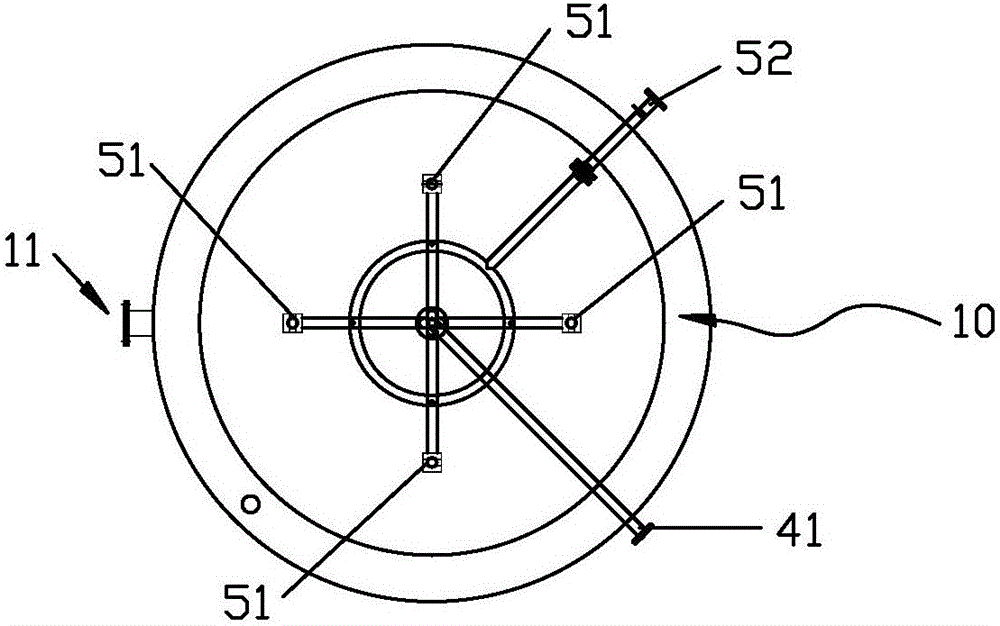

[0048] Please check Figure 1 to Figure 5 , a simultaneous nitrification and denitrification filter, comprising:

[0049] Pool body 10, the top of the pool body 10 is provided with an outlet weir 11, the preferred triangular weir of the outlet weir 11, the water outlet of the outlet weir 11 is controlled by a digital valve; Have a certain included angle, preferably 55°;

[0050] Filter material bed 20, filter material is for example sand; Filter material bed 20 is located in the tank body 10, and the top of filter material bed 20 is located below the liquid level in the tank body 10;

[0051] The water inlet system 30 includes a first water inlet outer pipe 31 and a water inlet water distributor that communicate with each other; the first water inlet outer pipe 31 is connected to a sewage water source, and the first water inlet outer pipe 31 is provided with a Venturi jet 311, the Venturi jet 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com