Structure defect rapid nondestructive test apparatus under high speed railway and method thereof

A technology for structural defects, high-speed railways, applied in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. It can solve the problems of high-level empty state, affecting the detection accuracy of the empty state at the bottom of the support layer, and low detection resolution of ground penetrating radar, so as to achieve the effect of speeding up the test speed, small residual vibration and high detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

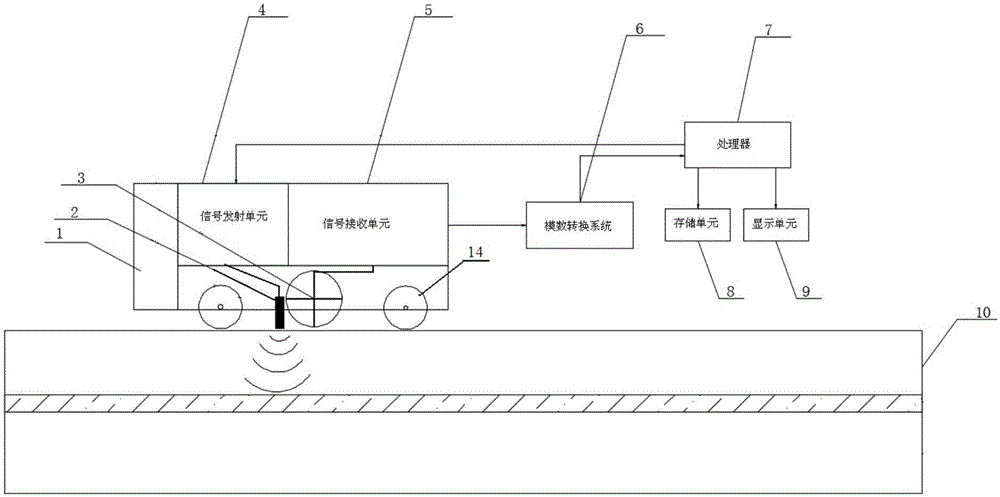

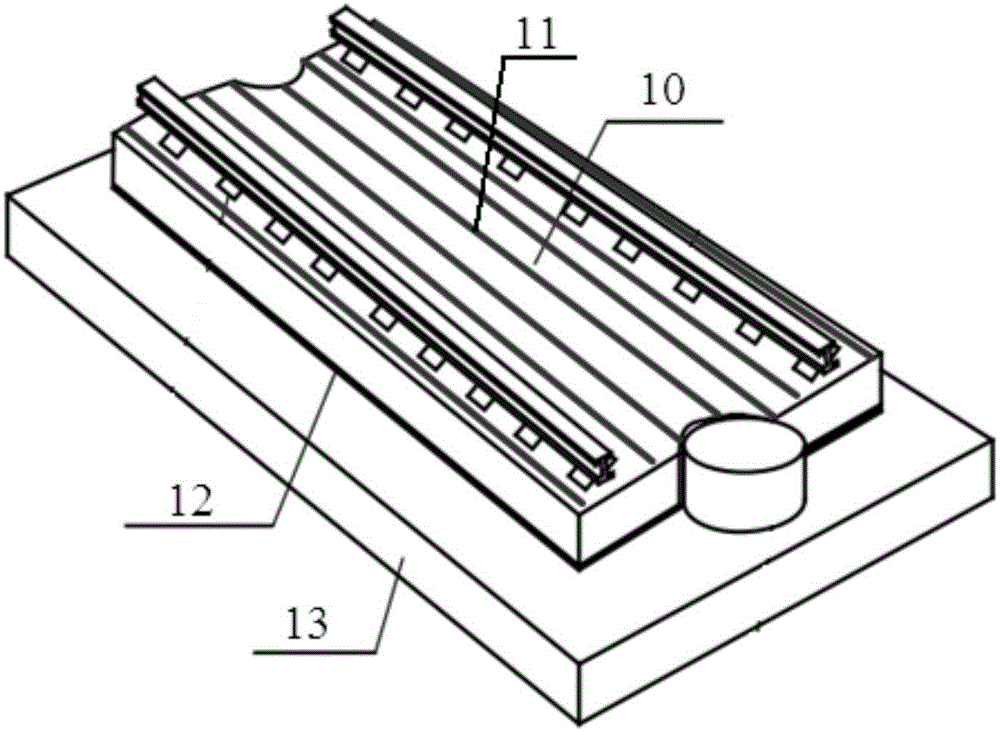

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

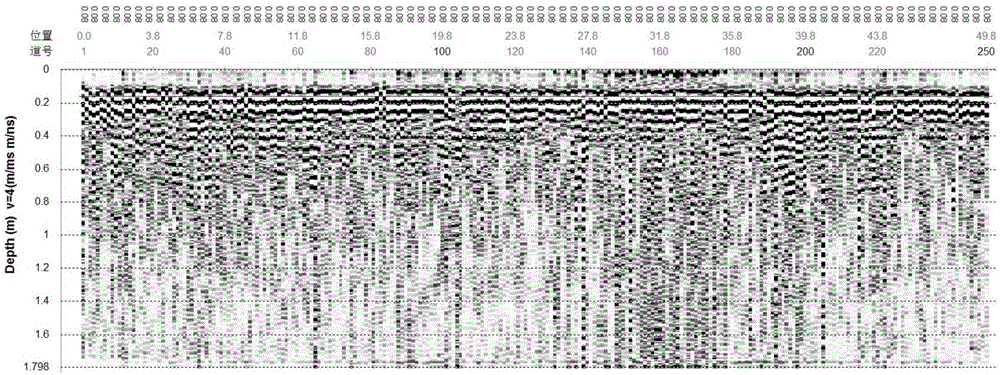

[0023] A rapid non-destructive detection device for structural defects under the high-speed railway track of the present invention, the device uses the giant magnetic transducer as the excitation source to excite high-frequency elastic wave signals on the ballastless track slab, and the elastic wave signals meet the supporting layer Reflections will occur in loose media such as hollows at the bottom and empty surfaces. The hub-type sensor receives the reflected signal under the ballastless track. By processing the received reflected signal and performing corresponding spectrum and image processing, the structural defects of the lower part of the ballastless track can be identified. Or the location of the disease, to achieve the purpose of rapid non-destructive detection of structural defects under the high-speed railway. The device as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com