Method for floating micro-fine particle hard-to-separate marmatite

A sphalerite and fine particle technology, applied in flotation, chemical instruments and methods, wet separation, etc., can solve the problems of low separation efficiency, difficult separation of mineral processing technology, and refractory lead-zinc sulfide ores. , to achieve the effect of high separation difficulty, good zinc beneficiation recovery rate, and promotion of selective floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, with 20 grams of hydroxyalkyl dithiocarbamate and 100 grams of sodium humate (molecular weight 10 4 ~10 6 ) and mix them under normal temperature and pressure with a beaker as a container and a magnetic stirrer for 40 to 60 minutes to obtain XKY-13.

Embodiment 2

[0021] Embodiment 2, with 20 gram hydroxyalkyl dithiocarbamate and 130 gram sodium humate (molecular weight 10 4 ~10 6 ) and mix them under normal temperature and pressure with a beaker as a container and a magnetic stirrer for 40 to 60 minutes to obtain XKY-13.

Embodiment 3

[0022] Embodiment 3, with 20 gram hydroxyalkyl dithiocarbamate and 160 gram sodium humate (molecular weight 10 4 ~10 6 ) and mix them under normal temperature and pressure with a beaker as a container and a magnetic stirrer for 40 to 60 minutes to obtain XKY-13.

[0023] 2. Preparation of sphalerite efficient and selective collector XKP-001

[0024] Example 1, 20 grams of ethyl xanthate, 10 grams of butyl xanthate and 10 grams of n-butyl dithiophosphate were used as raw materials, mixed according to the ratio of mass ratio 2:1:1, in It is prepared by using a beaker as a container at normal temperature and pressure and stirring with a magnetic stirrer for 15 to 30 minutes.

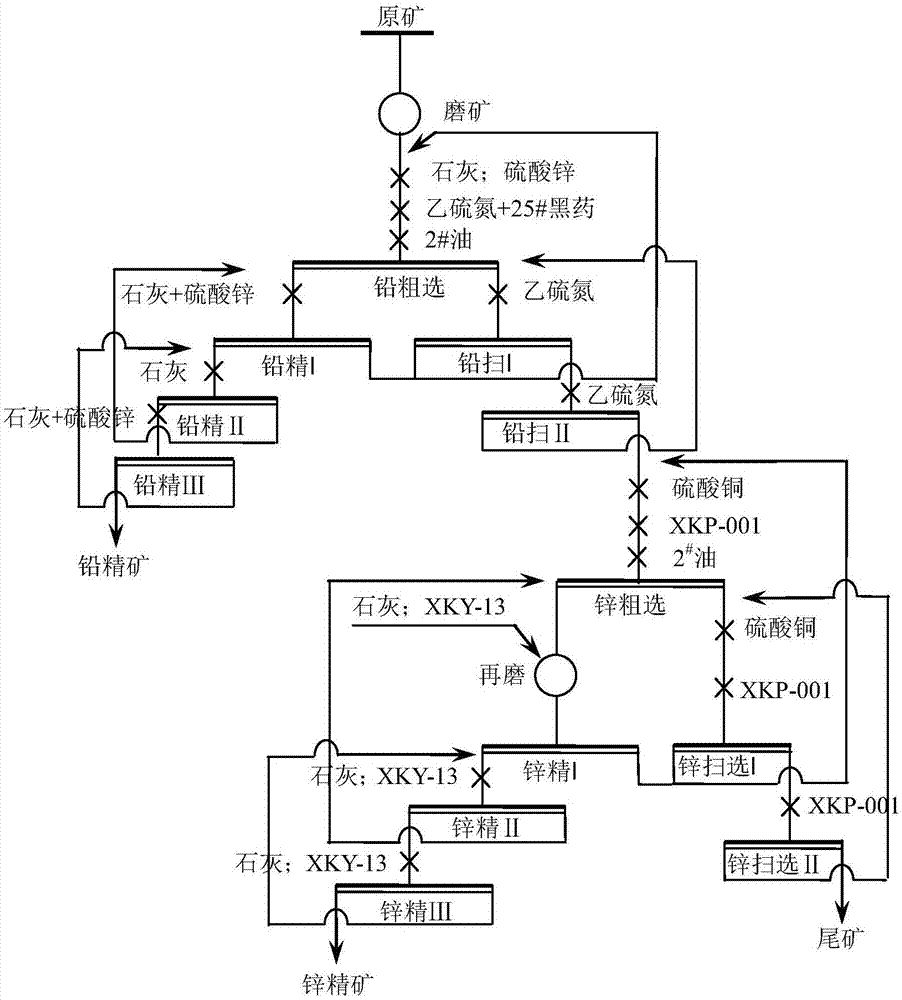

[0025] Third, the sorting process

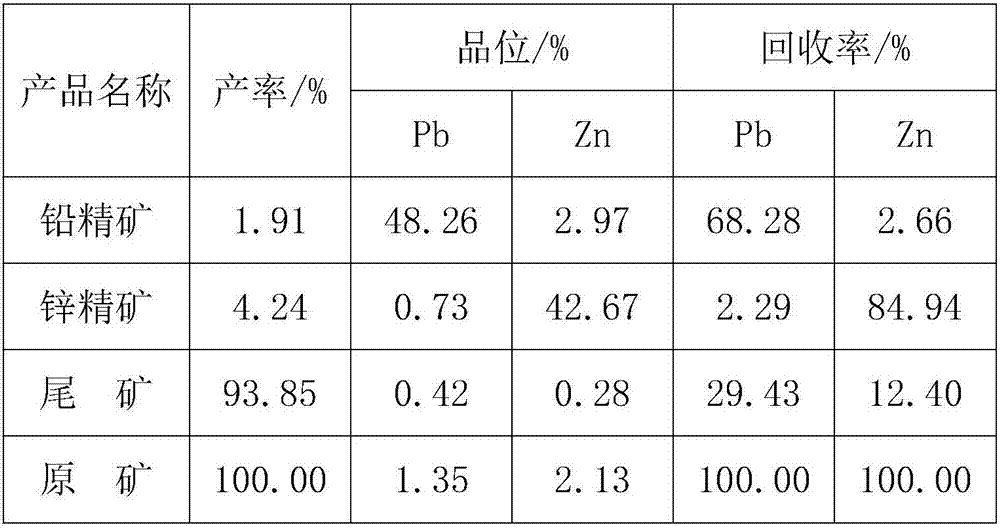

[0026] Embodiment 1, the selected ore is a certain iron-containing sphalerite, pyrrhotite, and pyrite fine-grained embedded type refractory lead-zinc sulfide ore. The raw ore contains 1.45% lead, 2.13% zinc, and 12.24% sulfur. %, iron 19.37%; the main metal minerals a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com