Low-alkali gel encapsulated microbial self-healing agent and application thereof

A microbial and self-healing technology, applied in the biological field, can solve the problems of limited slag or ceramsite loading, limited repair efficiency, strength loss, etc., to save maintenance funds, improve repair efficiency, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

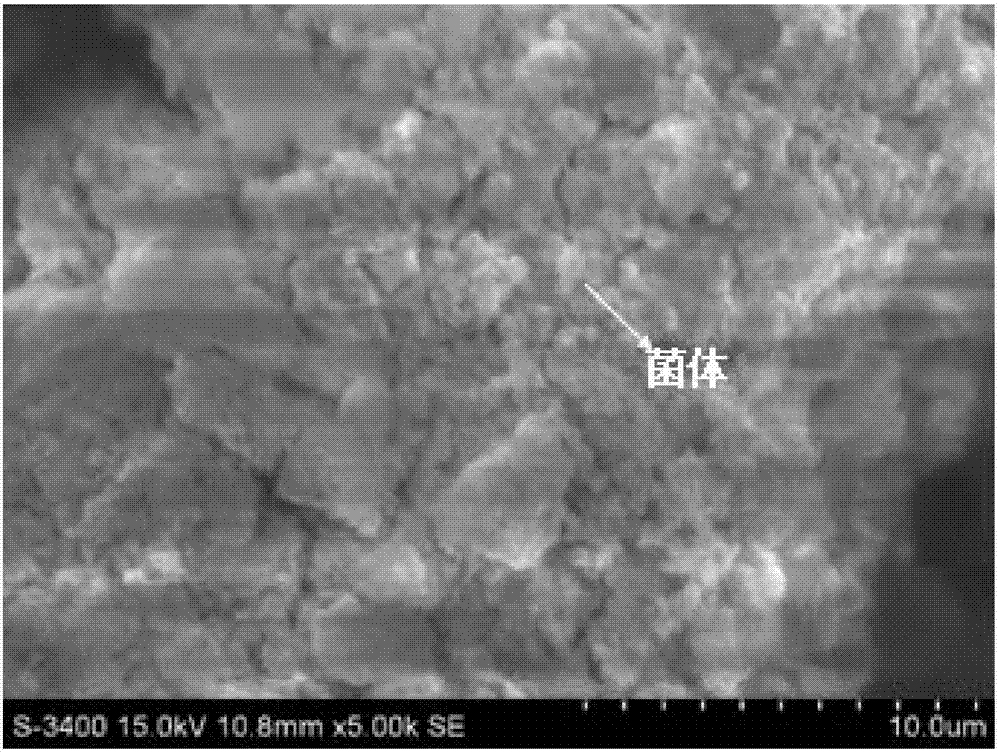

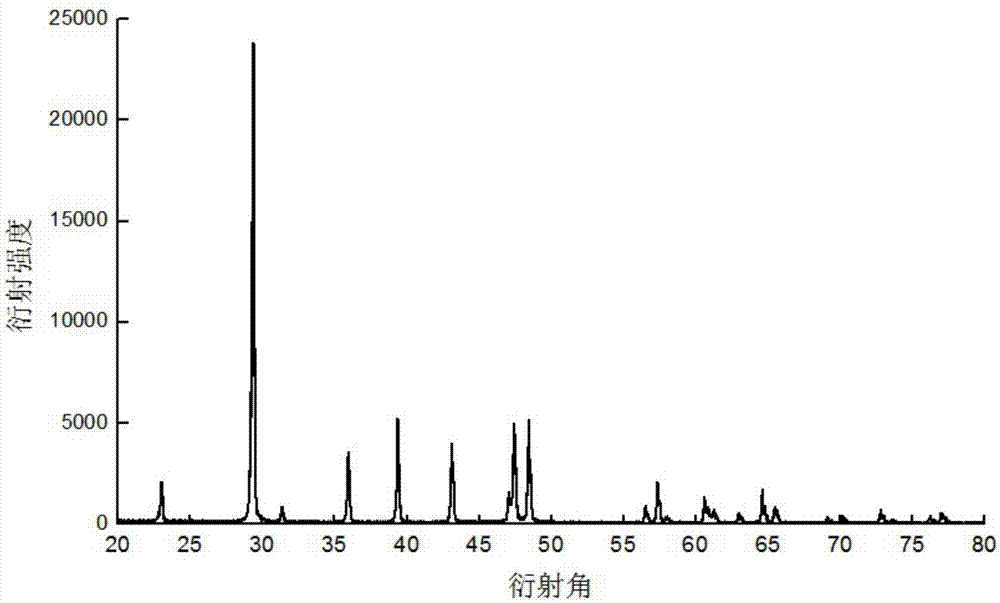

[0028] A low-alkali gelation encapsulated microbial self-repairing agent prepared by the following method. Inoculation of Sarcina pasteurii Sporosarcina pasteurii in a basal medium, and each liter of culture medium contains 3g beef extract, 5g peptone and 18g urea , At 37℃, shake culture at 100 rpm on a water bath shaker, 21 days later, centrifuge the obtained culture broth on a centrifuge at 4000 rpm for 10 min, remove the supernatant and collect the spore liquid with deionized water to concentrate the spore The final concentration of the liquid is controlled at 2×10 9 cell / ml. Prepare beef extract and peptone with a mass ratio of 1:1.6 as well as a low-alkali gelling medium with a mass ratio of sulphoaluminate cement and silica fume of 1:0.2. Then 40g of nutrients and 240g of low-alkali gelling medium are combined with After mixing 100g of water, stir for 5 minutes, then mix with the concentrated spore liquid at a volume ratio of 150:1. Place it at 20℃ and 100% relative humid...

Embodiment 2

[0030] A low-alkali gelation encapsulated microbial self-repairing agent prepared by the following method, inoculating Sarcina pasteurii into a basic medium, and each liter of culture medium contains 2.4g beef extract, 4g peptone and urea 16g, shake culture on a water bath shaker at a speed of 150rpm at 25°C, 14 days later, centrifuge the obtained culture broth on a centrifuge at 3000rpm for 20min, remove the supernatant and collect the spore broth with deionized water to concentrate the spores The final concentration of the bacterial liquid is controlled at 2×10 8 cell / ml. Prepare beef extract and peptone with a mass ratio of 1:2, and a low-alkali gelling medium with a mass ratio of sulphoaluminate cement and silica fume of 1:0.1, and then combine 36g of nutrients, 220g of low-alkali gelling medium with After mixing 100g of water, stir for 3min, then mix with the concentrated spore liquid at a volume ratio of 100:1. Place it in an environment of 20℃ and 100% relative humidity ...

Embodiment 3

[0032] A low-alkali gelation encapsulated microbial self-repairing agent prepared by the following method. Inoculation of Sarcina Pastoris Sporosarcina pasteurii in a basic medium, and each liter of culture medium contains 3.6 g of beef extract, 6 g of peptone and urea 20g, shake culture at 30°C on a water bath shaker at a speed of 120rpm, 28 days later, centrifuge the obtained culture broth on a centrifuge at 4000rpm for 15min, remove the supernatant and collect the spore broth with deionized water to concentrate the spores The final concentration of the bacterial liquid is controlled at 2×10 10 cell / ml. Prepare beef extract and peptone with a mass ratio of 1:1.8 and a low-alkali gelling medium with a mass ratio of sulphoaluminate cement and silica fume of 1:0.15. Then, 40g of nutrients, 230g of low-alkali gelling medium and After mixing 100g of water, stir for 5 minutes, then mix with the concentrated spore liquid at a volume ratio of 100:1. Place it at 22°C and 100% relative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com