Multifunctional composite supermolecule nanofiber self-assembly system and application thereof

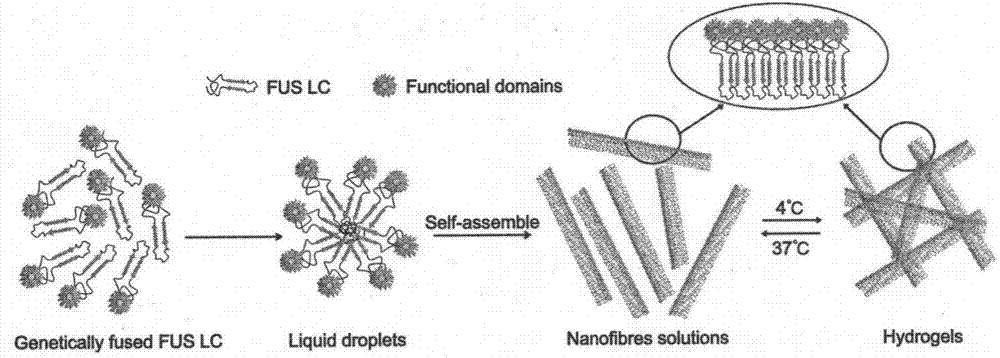

A nanofiber and supramolecular technology, applied in the field of protein self-assembly, can solve the problems of discount of practical value and neglect of functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

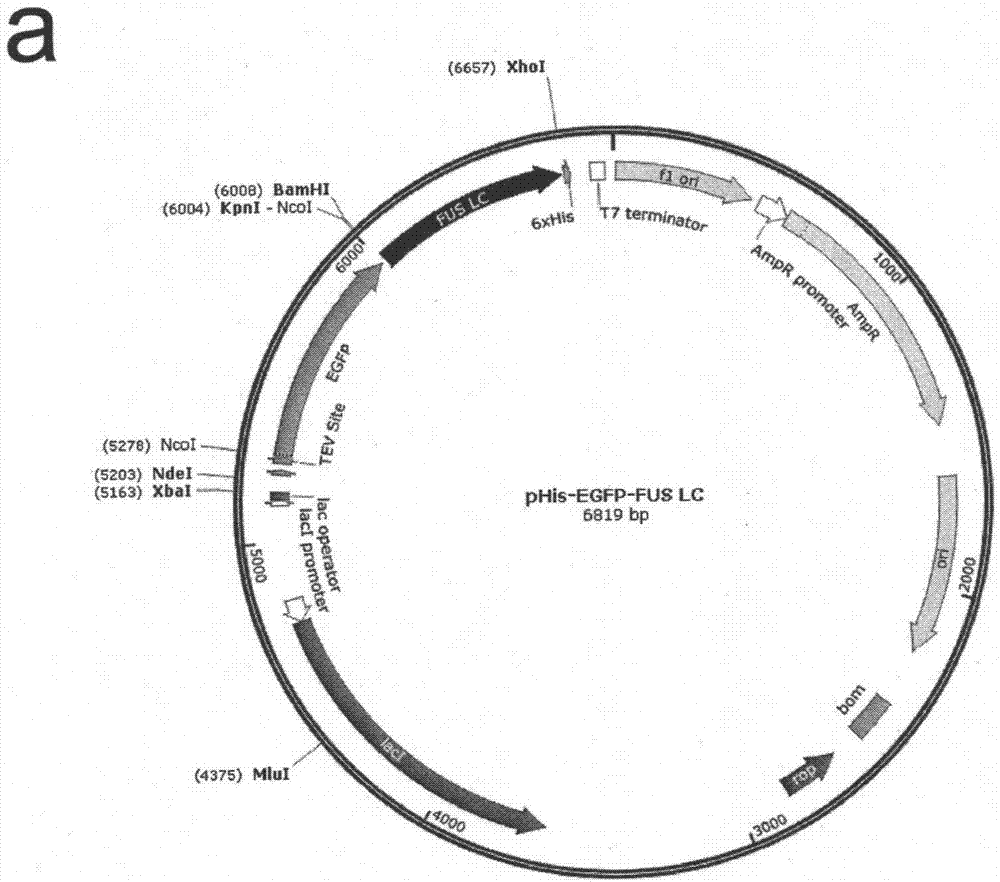

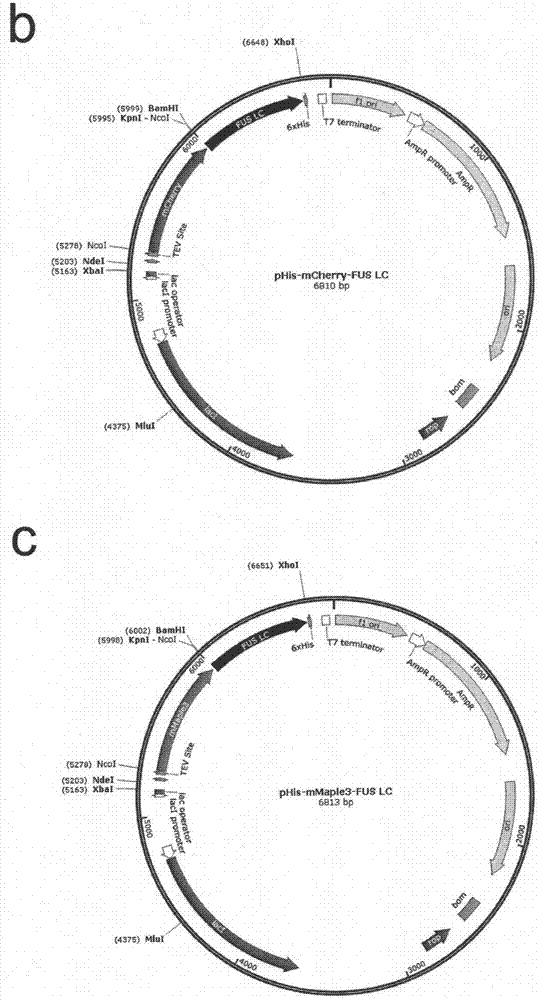

[0097] Example 1: Construction, expression and purification of functional FUS LC protein

[0098] The R-FUS LC expression plasmid was constructed, and the R-FUS LC expression plasmid was transformed into BL21(DE3) Escherichia coli to express the R-FUS LC fusion protein, and R is a functional protein.

[0099] The present invention utilizes a series of fusion plasmids expressing R-FUS LC, and combines peptide proteins with different functional groups. The plasmid map is as follows: figure 2 shown. Among them, pHis-FUS LC, pHis-mCherry-FUS LC, pHis-CFP-FUSLC and pHis-EGFP-FUS LC plasmids were donated by Professor McKnight's research group at Southwestern Medical College, USA. The amino acid sequence of FUS LC is shown in SEQ ID NO: 1 , the amino acid sequence of EGFP is shown in SEQ ID NO: 2, the amino acid sequence of mCherry is shown in SEQ ID NO: 3, the amino acid sequence of CFP is shown in SEQ ID NO: 4, the amino acid sequence of Histag is shown in SEQ ID NO: 10, and pHis...

Embodiment 2

[0124] Example 2: Preparation and characterization of single-component recombinant FUS LC nanofibers

[0125] A multifunctional composite supramolecular nanofiber self-assembly system, comprising pHis-mMaple3-FUS LC obtained in Example 1, pHis-PAtagRFP-FUS LC, pHis-EGFP-FUS LC-Spycatcher, pHis-EGFP-FUS LC- One of mefp5, pHis-FUS LC, pHis-mCherry-FUS LC, pHis-CFP-FUS LC and pHis-EGFP-FUSLC proteins.

[0126] The self-assembly system of multifunctional composite supramolecular nanofibers was used to prepare single-component recombinant FUS LC nanofibers:

[0127]The target protein obtained in Example 1 (pHis-mMaple3-FUS LC, pHis-PAtagRFP-FUS LC, pHis-EGFP-FUS LC-Spycatcher, pHis-EGFP-FUS LC-mefp5, pHis-FUS LC, pHis-mCherry -FUS LC, pHis-CFP-FUS LC, and pHis-EGFP-FUS LC) were concentrated to 40 μM, and left at 4°C (or room temperature) overnight to obtain a large number of supramolecular nanoparticles produced by the self-assembly of the target protein fiber, but there are stil...

Embodiment 3

[0139] Example 3: Preparation and Characterization of Bicomponent Random Copolymer Recombined FUS LC Nanofibers

[0140] A multifunctional composite supramolecular nanofiber self-assembly system, comprising the pHis-EGFP-FUS LC and pHis-mCherry-FUS LC proteins obtained in Example 1.

[0141] In view of the strong fiber growth and gel formation ability of the pHis-EGFP-FUS LC and pHis-mCherry-FUS LC proteins demonstrated in Example 2, the pHis-EGFP obtained in Example 1 with the same concentration of the substance (40 μM) -FUS LC and pHis-mCherry-FUS LC protein monomer solution were mixed together according to the ratio of 1:3, 1:1 and 3:1 to form the multifunctional composite supramolecular nanofiber self-assembly system and left at 4°C ( or dialyzed overnight) to self-assemble into recombinant FUSLC nanofibers ( Figure 9 a, 9b, 9c). Upright fluorescence microscope characterization as Figure 9 As shown in d, it can be proved that with the expansion of the component ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com