Blast furnace iron hook with water-cooling devices

A device and iron hook technology, which is applied in the field of blast furnace iron hooks, can solve the problems of accelerated erosion speed of iron ditch prefabricated parts, increased cost of lining and repair, and increased degree of erosion damage, etc., to solve the disadvantages of low water cooling efficiency, Improve service life and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

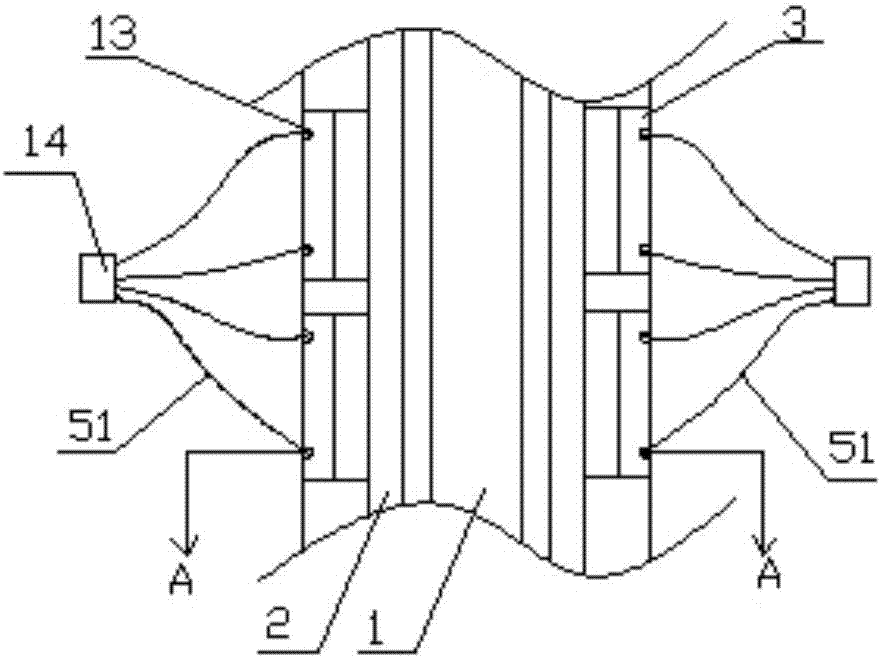

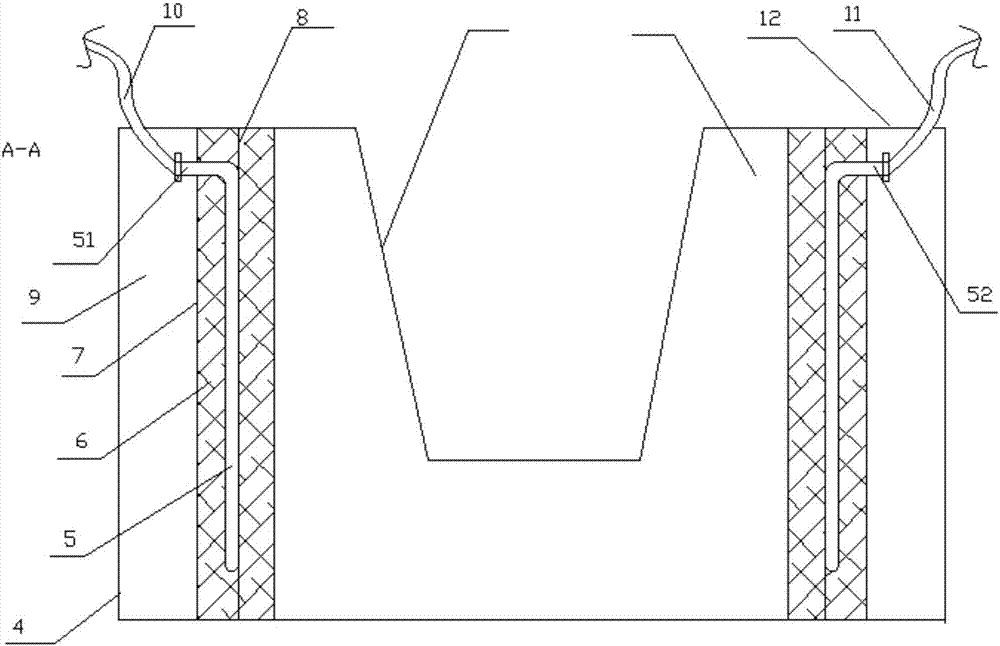

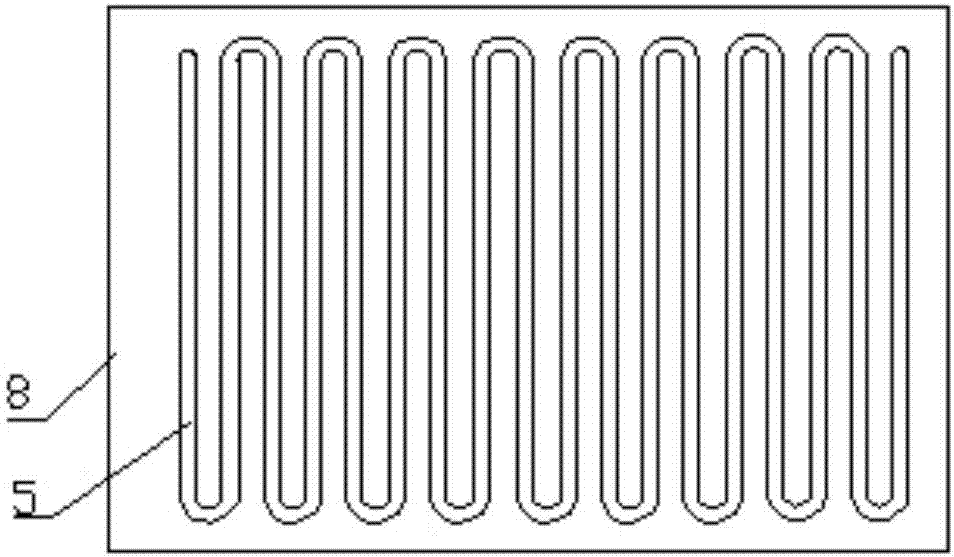

[0026] Such as figure 1 , figure 2 As shown, the present invention provides a blast furnace iron hook provided with a water cooling device, the iron hook includes: a groove 1, a protection groove 2 and a cooling water device 3, the groove 1 is a groove arranged on the top of the protection groove 2, The side wall of the protective tank 2 is vertically arranged, the bottom of the protective tank 2 is horizontally arranged, and cooling water devices are arranged on both sides of the protective tank 2; the water cooling device 3 includes: a shell 4, a water pipe 5, a cermet casting body 6, a second A metal back plate 7 and a second metal 8; the water pipe 5, the cermet cast body 6, the first metal back plate 7 and the second metal 8 are arranged in the ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com