Method for enriching lead from low-grade lead slag

A low-grade, lead slag technology, applied in the direction of improving process efficiency, can solve the problems of complex composition, high technical difficulty and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

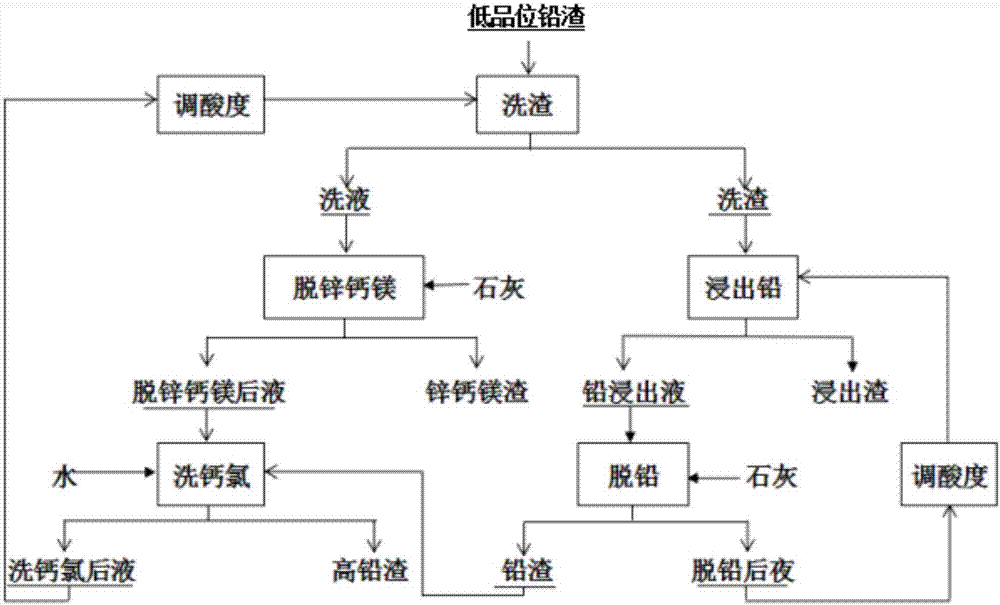

Image

Examples

Embodiment example 1

[0020] Lead sulfate slag contains Pb 17.5%, Zn 8%, Fe 3.7%, Mn 0.2%, Mg 0.38%, S 10%.

[0021] 1. Add lead sulfate slag to the liquid after calcium chloride washing at a liquid-solid ratio of 5:1, heat to 40-50°C, stir for 30 minutes, and filter to obtain the washing liquid and washing residue. The washing liquid contains Pb4 2~ 10g / L, the slag contains 20% Pb.

[0022] 2. Raise the temperature of the lotion to 70°C, add lime to adjust the pH>12, react for 30 minutes, and filter to obtain zinc-calcium-magnesium slag and dezincified calcium-magnesium solution. Zinc-calcium-magnesium slag contains Pb<0.1%, Zn 12%, Fe 2.4%, Mn 2.6%, Mg 2.6%, and after dezincification calcium-magnesium solution contains Pb<150mg / L, Zn<200mg / L, Fe<50mg / L , Mn<50mg / L, Mg 200mg / L, Cl 17g / L.

[0023] 3. Add the washed slag to the acid-adjusted solution (Pb 140mg / L, Zn 140mg / L, Ca 10g / L, Cl200g / L) at a liquid-solid ratio of 5:1, raise the temperature to 70-80°C, stir for 1 hour, and control The pH a...

Embodiment example 2

[0028] Lead sulfate slag contains 27% of Pb, 10.9% of Zn, 2.8% of Fe, 0.3% of Mn, 0.38% of Mg and 11% of S.

[0029] 1. Add lead sulfate slag to the liquid after calcium chloride washing at a liquid-solid ratio of 5:1, heat to 50-60°C, stir for 30 minutes, and filter to obtain the washing liquid and washing residue. The washing liquid contains Pb 179mg / L, Zn 3.9 g / L, Fe 0.8g / L, Mn 1.56g / L, Mg 0.62g / L, Cl3.8g / L, SO 4 2~ 11g / L, the slag contains 34% Pb.

[0030] 2. Raise the temperature of the lotion to 65°C, add lime to adjust the pH to 13-14, react for 30 minutes, and filter to obtain zinc-calcium-magnesium slag and dezincified calcium-magnesium liquor. Zinc-calcium-magnesium slag contains Pb<0.1%, Zn 16.5%, Fe 2.4%, Mn 2.6%, Mg 2.6%, and after dezincification calcium-magnesium solution contains Pb<50mg / L, Zn<50mg / L, Fe<50mg / L , Mn<50mg / L, Mg 200mg / L, Cl 25g / L.

[0031] 3. Add the washed slag to the acid-adjusted solution (Pb 500mg / L, Zn 300mg / L, Ca 13.5g / L, Cl210g / L) at a...

Embodiment example 3

[0036] Lead slag contains Pb 10%, Zn 13%, Fe 5%, Mn 0.8%, Mg 0.4%, S 12%.

[0037] 1. Add low-grade lead slag to the liquid after calcium chloride washing at a liquid-solid ratio of 5:1, heat to 60°C, stir for 30 minutes, and filter to obtain the washing liquid and washing residue. The washing liquid contains 200mg / L of Pb and 20g / L of Zn L, Fe 5g / L, Mn 1.3g / L, Mg 0.62g / L, Cl 3.8g / L, SO 4 2~ 13g / L, the washing residue contains 34% Pb.

[0038] 2. Raise the temperature of the lotion to 65°C, add lime to adjust the pH to 13-14, react for 30 minutes, and filter to obtain zinc-calcium-magnesium slag and dezincified calcium-magnesium liquor. Zinc-calcium-magnesium slag contains Pb<0.1%, Zn 16.5%, Fe 2.4%, Mn 2.6%, Mg 2.6%, and after dezincification calcium-magnesium solution contains Pb<50mg / L, Zn<50mg / L, Fe<50mg / L , Mn<50mg / L, Mg 200mg / L, Cl 25g / L.

[0039] 3. Add the washed residue to the acid-adjusted solution (Pb 100mg / L, Zn 100mg / L, Ca 8.1g / L, Cl180g / L) at a liquid-solid r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com