Forming paper coated with natural plant extract on both sides and preparation method thereof

A natural plant, double-sided coating technology, applied in papermaking, coating, paper coating, etc., can solve the problems of inconsistent sensory quality of cigarettes, small amount of coating of functional components, etc., and achieve product safety, non-toxicity, miscellaneous gas and The effect of less irritation and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

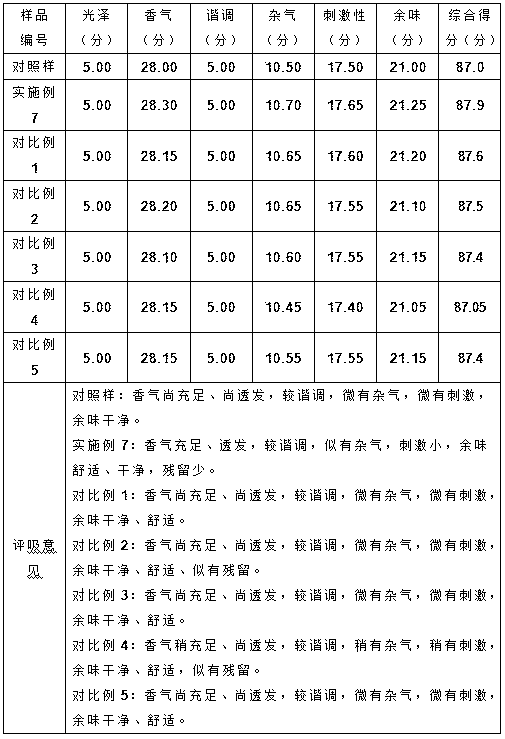

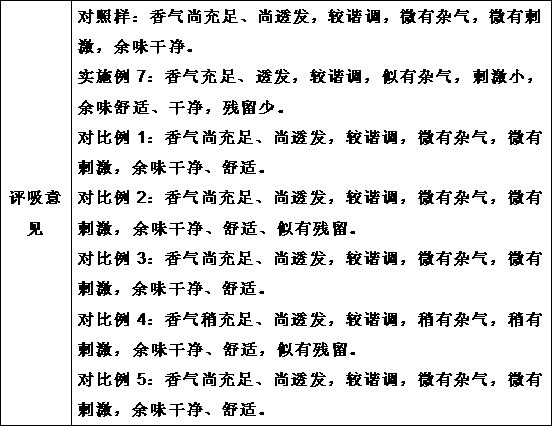

Examples

Embodiment 1

[0042] A kind of preparation method of the forming paper of double-sided coating natural plant extract, comprises the steps:

[0043] In step (1), the natural plant material with a particle size of 20 mesh is reflux extracted with 80% ethanol for 3 hours, filtered with a filter cloth of 150 mesh, and the filtrate is concentrated to a density of 0.792g / ml 3 , to obtain a concentrated extract; during reflux extraction, the weight ratio of natural plant material and volume concentration of 80% ethanol is 1:6;

[0044] Step (2), dilute the concentrated extract with a mixed solvent of propylene glycol and absolute ethanol to a solid mass concentration of 4%, to obtain a coating solution; wherein, in the mixed solvent, the volume ratio of propylene glycol to absolute ethanol is 7: 3;

[0045] Step (3), apply the coating solution to the front and back of the forming paper with a paper coating machine, dry, roll and roll to obtain a forming paper coated with natural plant extracts on...

Embodiment 2

[0050] A kind of preparation method of the forming paper of double-sided coating natural plant extract, comprises the steps:

[0051] In step (1), the natural plant material with a particle size of 60 mesh is reflux extracted with 80% ethanol for 4 hours, filtered with a 200 mesh filter cloth, and the filtrate is concentrated to a density of 0.808g / ml 3 , to obtain a concentrated extract; during reflux extraction, the weight ratio of natural plant material and volume concentration of 80% ethanol is 1:9;

[0052] Step (2), dilute the concentrated extract with a mixed solvent of propylene glycol and absolute ethanol to a solid mass concentration of 20%, to obtain a coating solution; wherein, in the mixed solvent, the volume ratio of propylene glycol to absolute ethanol is 7: 4;

[0053] Step (3), apply the coating solution to the front and back of the forming paper with a paper coating machine, dry, roll and roll to obtain a forming paper coated with natural plant extracts on b...

Embodiment 3

[0058] A kind of preparation method of the forming paper of double-sided coating natural plant extract, comprises the steps:

[0059] In step (1), the natural plant material with a particle size of 40 mesh is reflux extracted with 80% ethanol for 3.5 hours, filtered with a filter cloth of 160 mesh, and the filtrate is concentrated to a density of 0.8000g / ml 3 , to obtain a concentrated extract; during reflux extraction, the weight ratio of natural plant material and volume concentration of 80% ethanol is 1:7;

[0060] Step (2), dilute the concentrated extract with a mixed solvent of propylene glycol and absolute ethanol to a solid mass concentration of 10%, to obtain a coating solution; wherein, in the mixed solvent, the volume ratio of propylene glycol to absolute ethanol is 7: 3.6;

[0061] Step (3), apply the coating solution to the front and back of the forming paper with a paper coating machine, dry, roll and roll to obtain a forming paper coated with natural plant extra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gas permeability | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com