Process for injecting endogenous microbial oil displacement activating agents on sites

A technology of endogenous microorganisms and activators, which is applied in the production of fluids, wellbore/well components, and earth-moving drilling, etc., can solve the problems of slow microbial metabolism, unsatisfactory oil displacement effect, and low proportion, etc. The effect of overall proliferation and metabolism, enhanced oil recovery, and enhanced oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

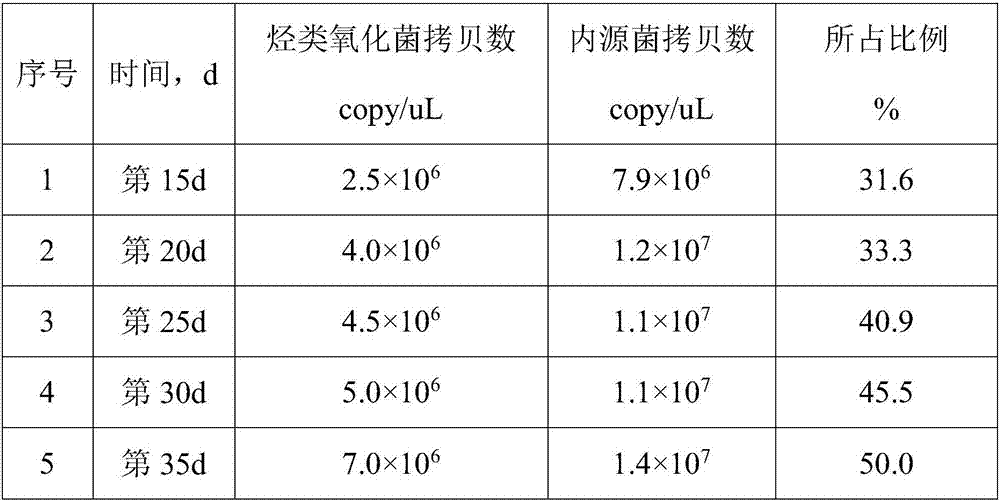

[0023] A block B of Shengli Oilfield 12 , the reservoir temperature is 65°C, the pressure is 11.2MPa, and the permeability is 950×10 -3 μm 2 , the geological reserves are 3.6×10 4 t. Water content 93.2%. After the screening of activators, the inorganic nutrient activator was KNO 3 0.3wt%, K 2 HPO 4 0.01wt%, and the organic nutrition activator is glucose 3.2wt%. Utilize activator field injection technique of the present invention to carry out field test, concrete steps are as follows:

[0024] (1) On-site injection stage of inorganic nutrient activator

[0025] First, use the injected water in the test block to configure the inorganic nutrient activator solution, KNO 3 0.3wt%, K 2 HPO 4 0.01wt%; secondly, use the high-pressure injection pump to continuously inject the inorganic nutrient activator solution from the water injection well in the test block, and the injection speed is 80m 3 / d; On the 15th day after the on-site injection of inorganic nutrient activator...

Embodiment 2

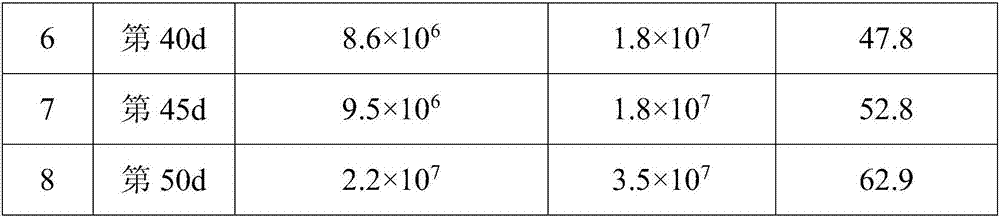

[0039] A block C of Shengli Oilfield 2 , the reservoir temperature is 70°C, the pressure is 10.5MPa, and the permeability is 880×10 -3 μm 2 , The geological reserves are 7.2×10 4t. Water content 90.3%. After the screening of activators, the inorganic nutrient activator was KNO 3 0.1wt%, KH 2 PO 4 0.04wt%, and the organic nutrition activator is 5.0wt% starch. Utilize activator field injection technique of the present invention to carry out field test, concrete steps are as follows:

[0040] (1) On-site injection stage of inorganic nutrient activator

[0041] First, use the injected water in the test block to configure the inorganic nutrient activator solution, KNO 3 0.1wt%, KH 2 PO 4 0.04wt%; secondly, use the high-pressure injection pump to continuously inject the inorganic nutrient activator solution from the water injection well in the test block, and the injection speed is 90m 3 / d; On the 25th day after the on-site injection of inorganic nutrient activators, ...

Embodiment 3

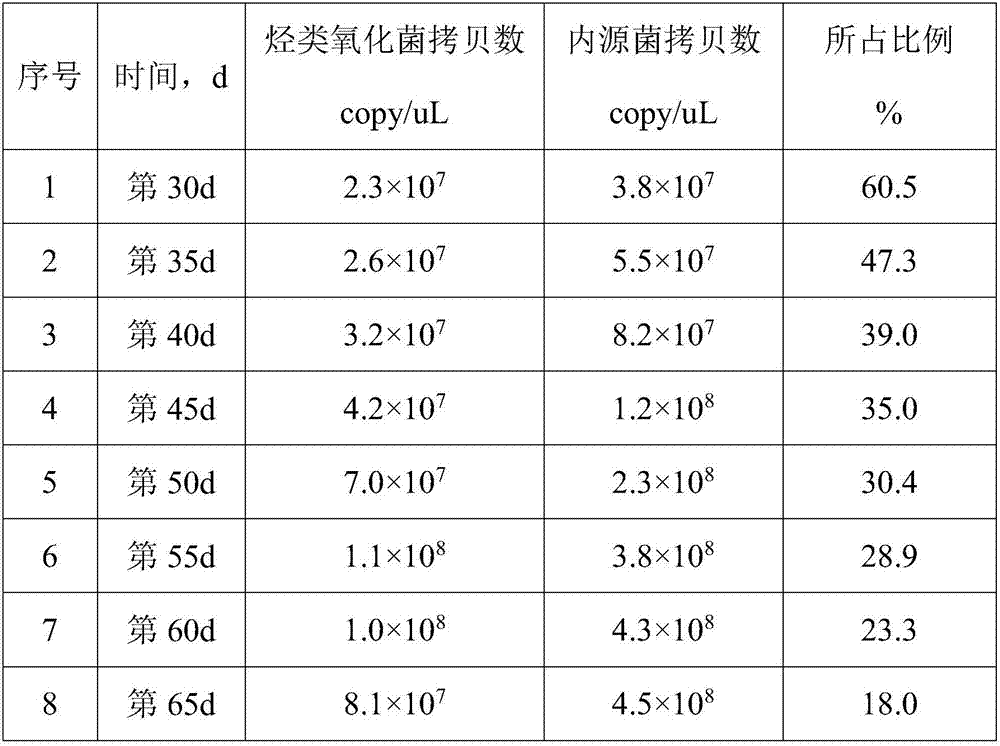

[0055] A block B of Shengli Oilfield 5 , the reservoir temperature is 60°C, the pressure is 12.0MPa, and the permeability is 1150×10 -3 μm 2 , the geological reserves are 5.0×10 4 t. Water content 91.5%. After screening the activator, the inorganic nutrient activator was NaNO 3 0.5wt%, K 2 HPO 4 0.05wt%, and the organic nutrition activator is molasses 1.0wt%. Utilize activator field injection technique of the present invention to carry out field test, concrete steps are as follows:

[0056] (1) On-site injection stage of inorganic nutrient activator

[0057] Firstly, use the injected water in the test block to configure the inorganic nutrient activator solution, NaNO 3 0.5wt%, K 2 HPO 4 0.05wt%; secondly, use the high-pressure injection pump to continuously inject the inorganic nutrient activator solution from the water injection well in the test block, and the injection speed is 100m 3 / d; On the 30th day after the on-site injection of inorganic nutrient activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com