Device and method for realizing multi-permeability continuously changing toroidal core inductance

A technology of toroidal cores and toroidal inductors, used in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problem of uneven magnetic flux density distribution, and achieve the effect of uniform magnetic flux density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

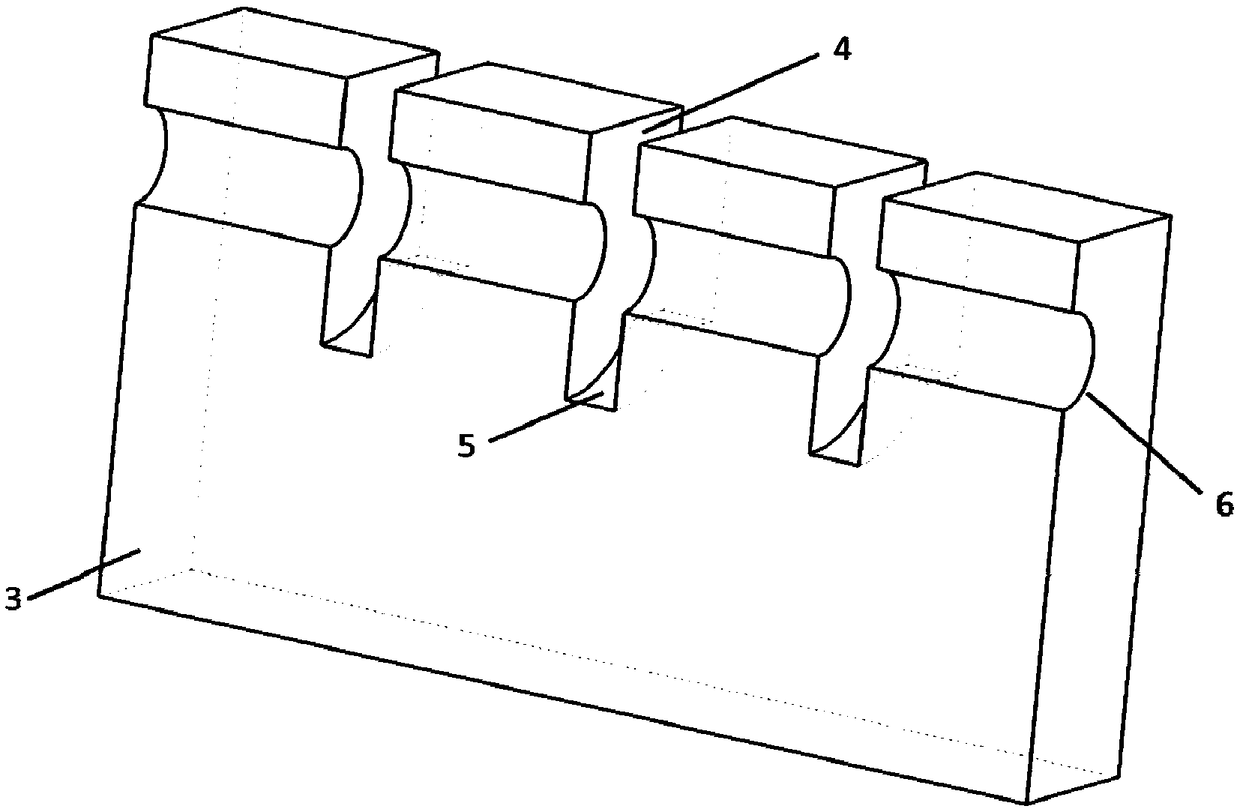

Method used

Image

Examples

Embodiment 1

[0045] Utilize the clamp device prepared in the specific embodiment, operate as follows:

[0046] (a) 2g of nickel-zinc-copper ferrite powder and 0.2g of polyvinyl alcohol (PVA) solution with a mass fraction of 5% were mixed uniformly in an agate mortar.

[0047] (b) Put the homogeneously mixed product into a mold, hold the pressure at 300MPa for 5 minutes, and press to form it. The pressed annular inductor green body 1 has an outer diameter of 20 mm, an inner diameter of 10 mm, and a thickness of 3.8 mm.

[0048](c) Put the pressed annular inductor green body 1 on the device of the present invention that can form a gradient temperature distribution for sintering, put the device in a tube furnace, and then pass air into the condensation pipe 2, and the ventilation flow rate is 12L / min, sintering at 1050°C for 2 hours.

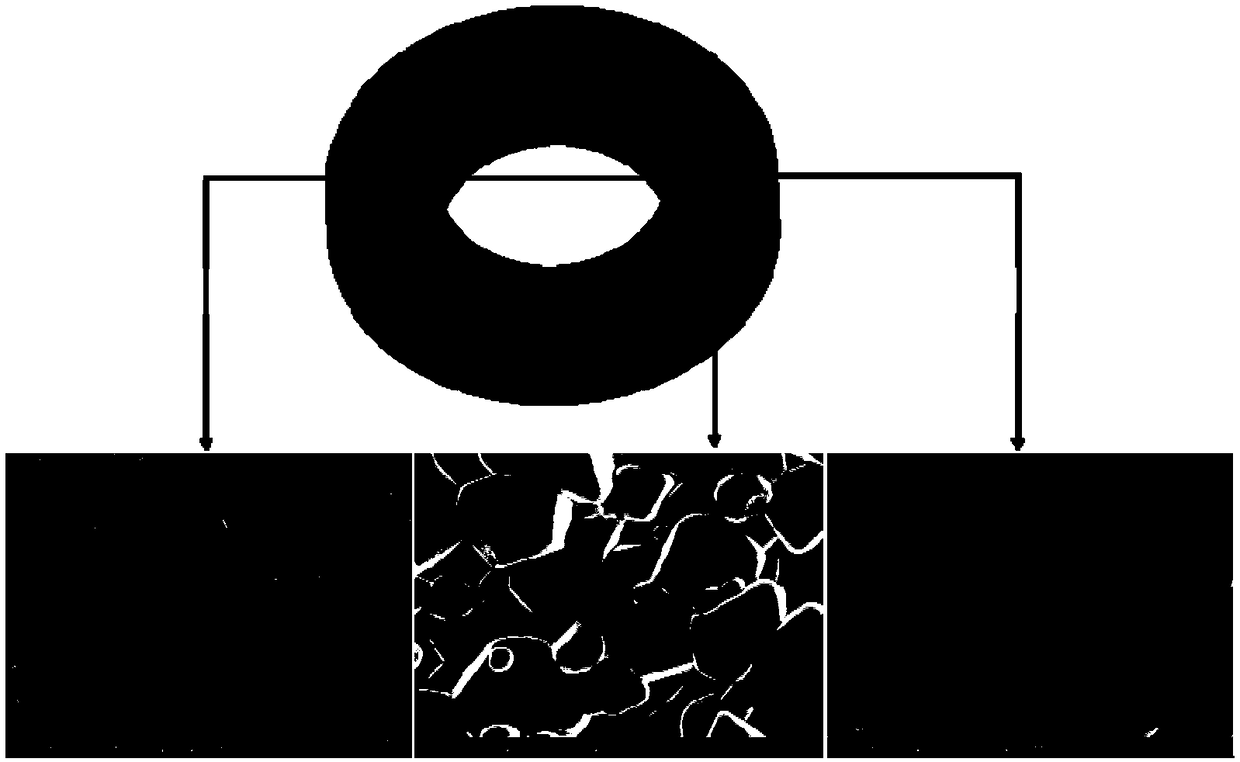

[0049] (d) The sample is cooled with the furnace, and taken out for SEM testing to observe the grain size along the radial direction of the magnetic ring. I...

Embodiment 2

[0051] Utilize the clamp device prepared in the specific embodiment, operate as follows:

[0052] (a) Take 2g of nickel-zinc-copper ferrite powder and 0.3g of polyvinyl alcohol (PVA) solution with a mass fraction of 6% and mix them uniformly in an agate mortar.

[0053] (b) Put the uniformly mixed product into a mold, hold the pressure at 400 MPa for 4 minutes, and press to form it. The pressed annular inductor green body 1 has an outer diameter of 20 mm, an inner diameter of 10 mm, and a thickness of 3.7 mm.

[0054] (c) Put the pressed annular inductor green body 1 on the device of the present invention capable of forming a gradient temperature distribution for sintering, put the device in a tube furnace, and then feed water into the condensation pipe 2 at a flow rate of 100ml / min, sintering at 1000°C for 2 hours.

[0055] (d) The sample is cooled with the furnace, and taken out for SEM testing to observe the grain size along the radial direction of the magnetic ring. It ...

Embodiment 3

[0057] Utilize the clamp device prepared in the specific embodiment, operate as follows:

[0058] (a) 2g of nickel-zinc-copper ferrite powder and 0.4g of polyvinyl alcohol (PVA) solution with a mass fraction of 10% were mixed uniformly in an agate mortar.

[0059] (b) Put the uniformly mixed product into a mold, hold the pressure at 500 MPa for 3 minutes, and press to form it. The pressed annular inductor green body 1 has an outer diameter of 20 mm, an inner diameter of 10 mm, and a thickness of 3.5 mm.

[0060] (c) Put the pressed annular inductor green body 1 on the device of the present invention capable of forming a gradient temperature distribution for sintering, put the device in a tube furnace, and then feed water into the condensation pipe 2 at a flow rate of 90ml / min, sintering at 950°C for 2 hours.

[0061] (d) The sample is cooled with the furnace, and taken out for SEM testing to observe the grain size along the radial direction of the magnetic ring. It is found...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com