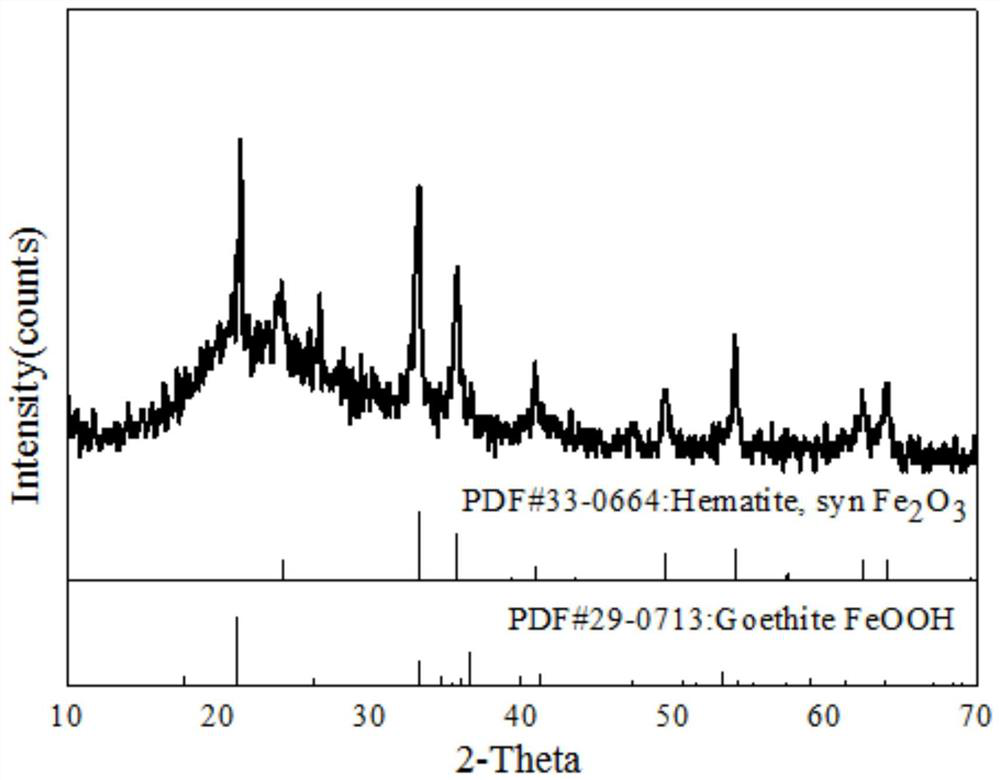

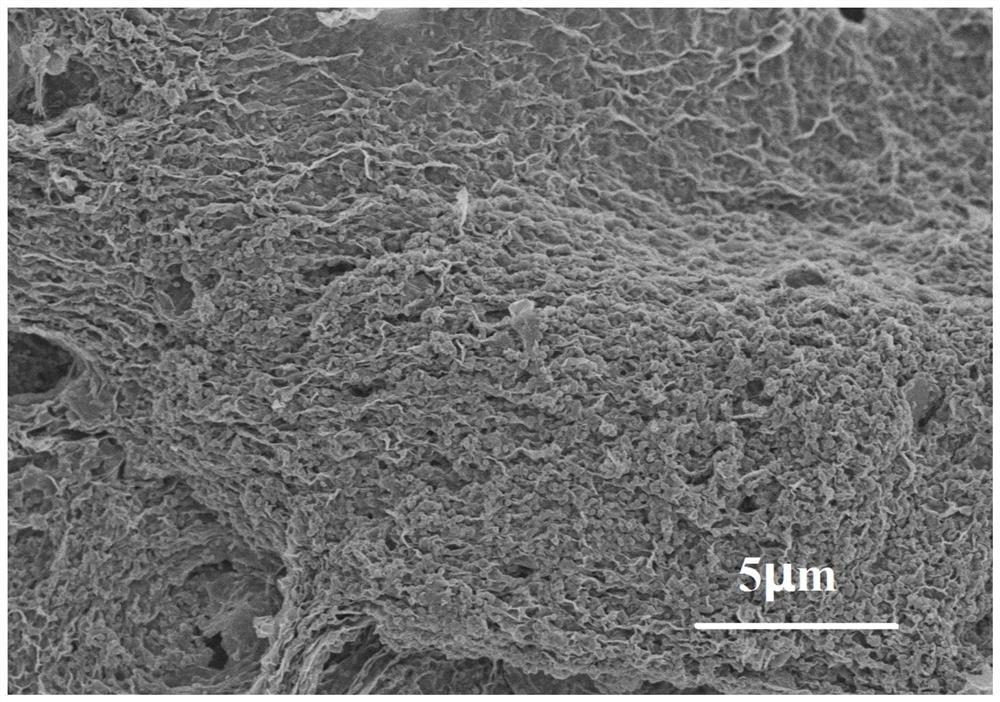

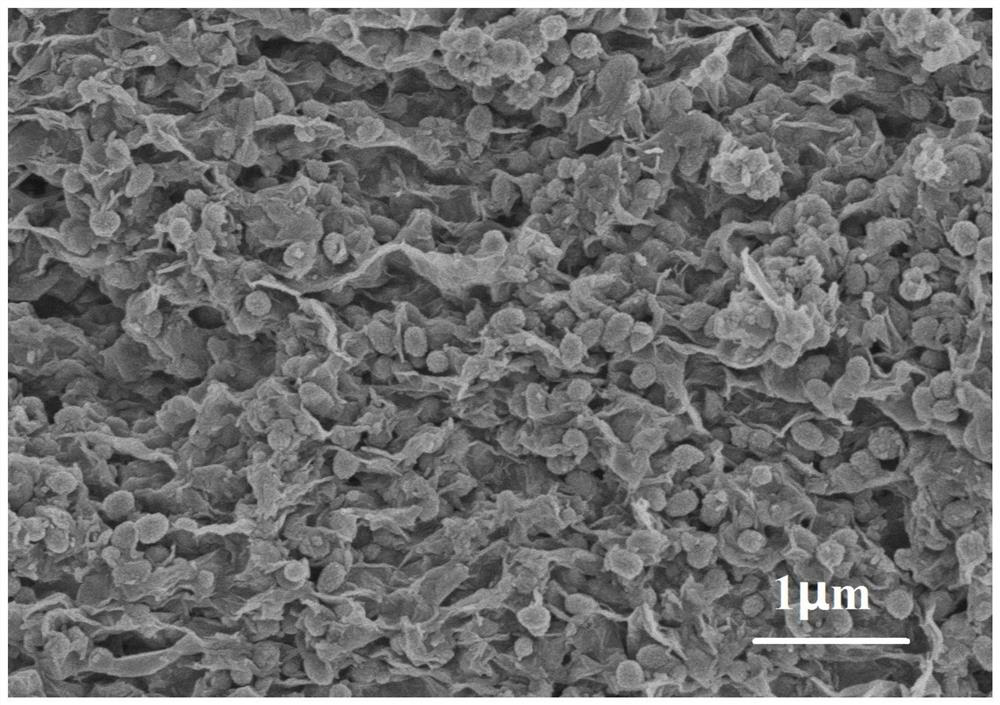

A preparation method of graphene-loaded iron oxide self-assembled mulberry-like structure lithium-ion battery negative electrode material

A technology of lithium-ion batteries and iron oxides, applied in the field of electrochemistry, can solve the problems of poor conductivity of iron oxides, and achieve the effects of low cost, easy implementation, and simple experimental methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Disperse commercially available graphene oxide in 25 mL of ethanol to form a 1 mg / mL solution, and then use a 300W ultrasonic generator to sonicate for 1 hour to form a uniformly dispersed graphene oxide suspension A;

[0023] 2) Add the analytically pure soluble iron salt ferrous chloride into 25mL deionized water, stir to fully dissolve the iron salt, then add it to the suspension A, and configure it into a mixed solution B of iron salt and graphene oxide, wherein The concentration of iron salt is 0.05mol / L;

[0024] 3) Pour the mixed solution B prepared above into a homogeneous hydrothermal reactor with a filling degree of 30%, then seal the reactor, put it into a homogeneous hydrothermal reactor at 50° C. for 10 minutes, Naturally cool to room temperature after the reaction to obtain product C;

[0025] 4) The product C was washed with water and alcohol for 3 times in a centrifuge, each centrifugation time was 1 min, and the centrifugation speed was 3000 rpm, an...

Embodiment 2

[0031] 1) Disperse commercially available graphene oxide in 30 mL of ethanol to form a 2 mg / mL solution, and then use a 300W ultrasonic generator to sonicate for 1 hour to form a uniformly dispersed graphene oxide suspension A;

[0032] 2) Add the analytically pure soluble iron salt ferrous chloride into 20mL deionized water, stir to fully dissolve the iron salt, then add it to the suspension A, and configure it into a mixed solution B of iron salt and graphene oxide, wherein The concentration of iron salt is 0.05mol / L;

[0033] 3) Pour the mixed solution B prepared above into a homogeneous hydrothermal reactor with a filling degree of 80%, then seal the reactor, put it into a homogeneous hydrothermal reactor at 70° C. for 20 minutes, Naturally cool to room temperature after the reaction to obtain product C;

[0034] 4) The product C was washed with water and alcohol for 3 times in a centrifuge, each centrifugation time was 1 min, and the centrifugation speed was 4000 rpm, an...

Embodiment 3

[0037] 1) Disperse commercially available graphene oxide in 35 mL of ethanol to form a 3 mg / mL solution, and then use a 300W ultrasonic generator to ultrasonicate for 3 hours to form a uniformly dispersed graphene oxide suspension A;

[0038] 2) Add the analytically pure soluble iron salt ferrous chloride into 15mL deionized water, stir to fully dissolve the iron salt, then add it to the suspension A, and configure it into a mixed solution B of iron salt and graphene oxide, wherein The concentration of iron salt is 0.5mol / L;

[0039] 3) Pour the mixed solution B prepared above into a homogeneous hydrothermal reactor with a filling degree of 60%, then seal the reactor, put it into a homogeneous hydrothermal reactor at 150° C. for 30 minutes, Naturally cool to room temperature after the reaction to obtain product C;

[0040]4) The product C was washed with water and alcohol for 3 times in a centrifuge, each centrifugation time was 2 minutes, and the centrifugation speed was 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com