Phase-shift started permanent magnet motor for drainage pumps

A technology for permanent magnet motors and drainage pumps, which is applied in the direction of electric components, machines/engines, pumps, etc., and can solve the problems of low efficiency of permanent magnet motors, small starting torque of permanent magnet motors, and drop in electromagnetic torque of ordinary washing machine drainage pumps, etc. problem, to achieve the effect of increasing the starting torque of the motor, improving the efficiency of the motor, and reducing the input power of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

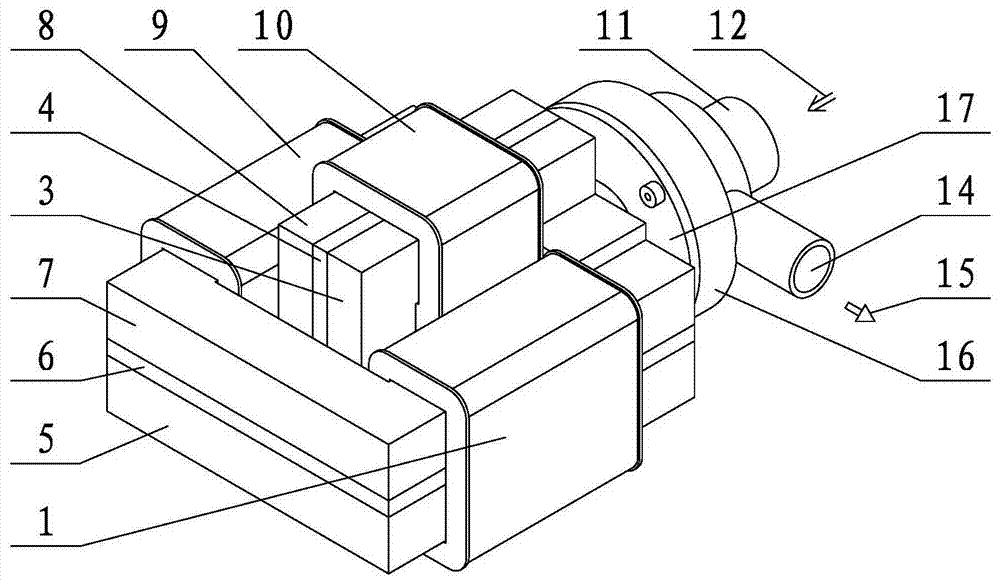

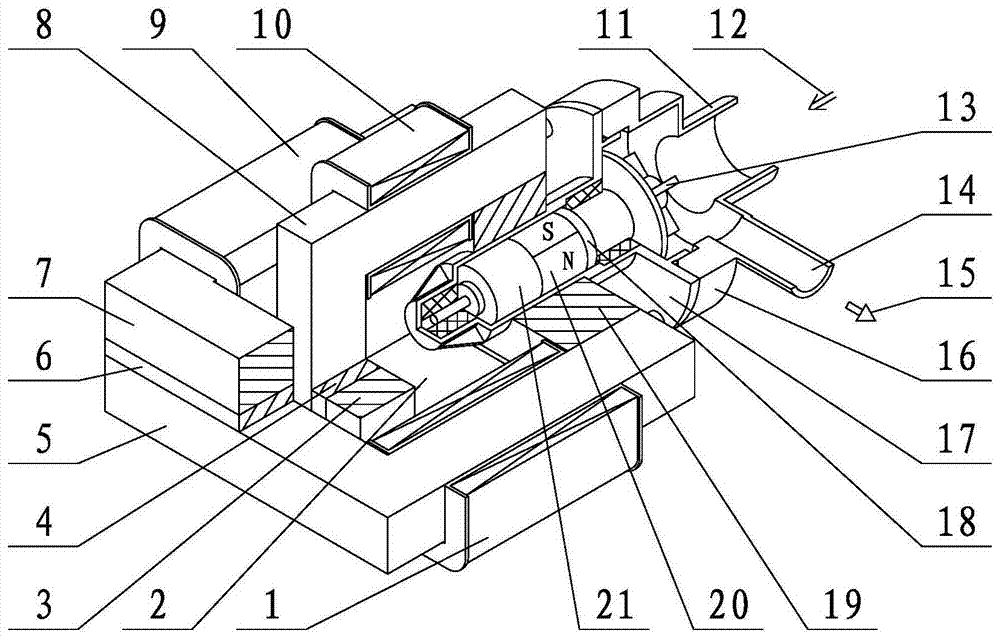

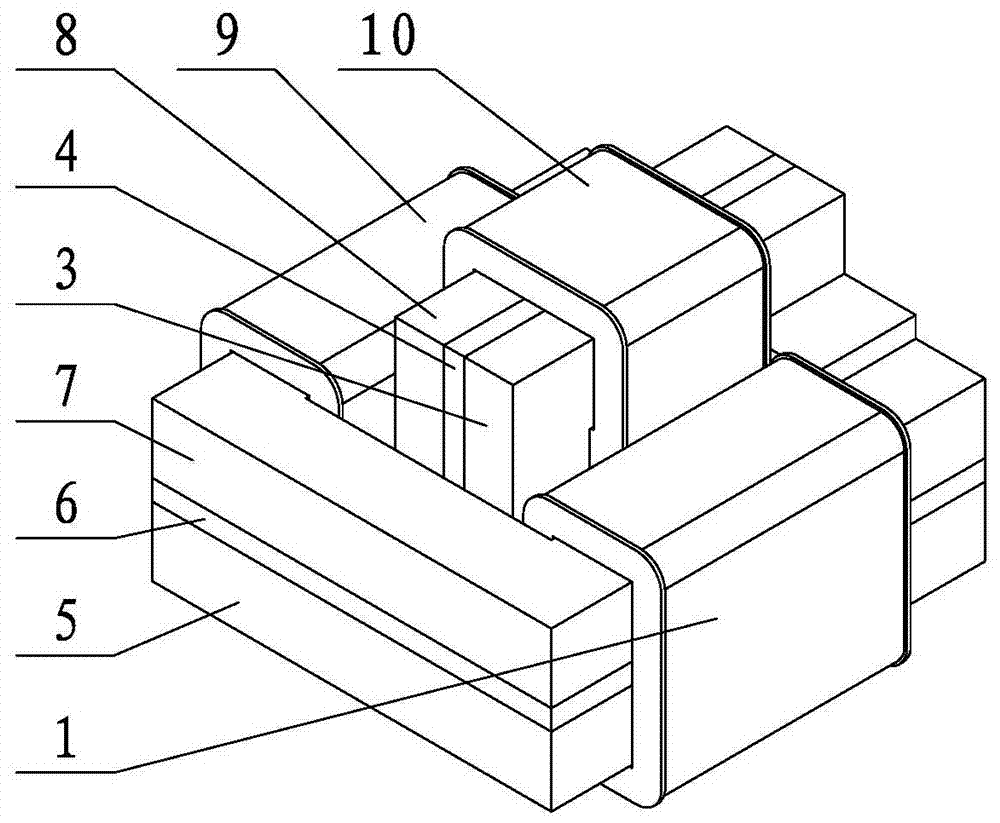

[0023] The present invention is further described below in conjunction with accompanying drawing.

[0024] refer to Figure 1 to Figure 3 , Figure 11 to Figure 16 The phase shift start permanent magnet motor of the drainage pump is applied to the drainage pump of the washing machine, and the drainage pump of the washing machine includes a water pump part and the motor. The water pump parts include casing two 16, casing one 17, shaft sleeve one 46, shaft sleeve two 47, sealing ring 49, rotor parts, and the rotor parts include motor rotor part 18 and impeller 13. The first shaft sleeve 46 and the second shaft sleeve 47 are installed in the inner cavity of the first housing 17, the sealing ring 49 is installed at one end of the first housing 17, the other end of the first housing 17 has a sealing sleeve 48, and one end of the second housing 16 has a water inlet pipe 11 And the water outlet pipe 14, the other end of the shell two 16 and the one end of the shell one 17 with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com