Pickering emulsion prepared from peanut protein isolate and preparation method thereof

A technology of peanut protein isolate and peanut protein, which is applied in the field of food processing, can solve problems such as the unseen Pickering emulsion method, and achieve the effects of low cost, easy operation and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment provides a kind of method using peanut protein isolate to prepare Pickering emulsion, concrete steps are as follows:

[0043] a. Prepare 6% peanut protein isolate solution, stir it for 2 hours and put it in a refrigerator at 4°C overnight to refrigerate overnight to fully hydrate the protein to obtain a peanut protein dispersion;

[0044] b. Adjust the pH of the peanut protein dispersion to 6.3, heat it in a 70°C water bath for 14 minutes, cool to room temperature, add (7U / g peanut protein isolate) transglutaminase, and exchange in a 37°C water bath The joint reaction was carried out for 1 hour, and then heated at 85°C for 10 minutes to obtain a gel block;

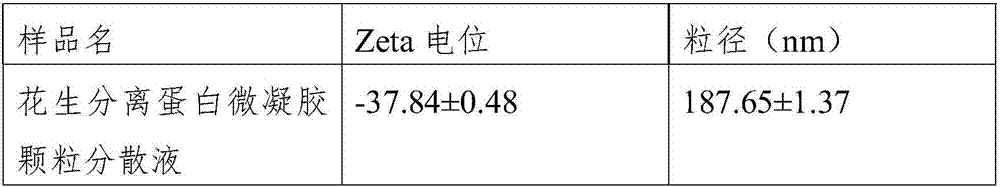

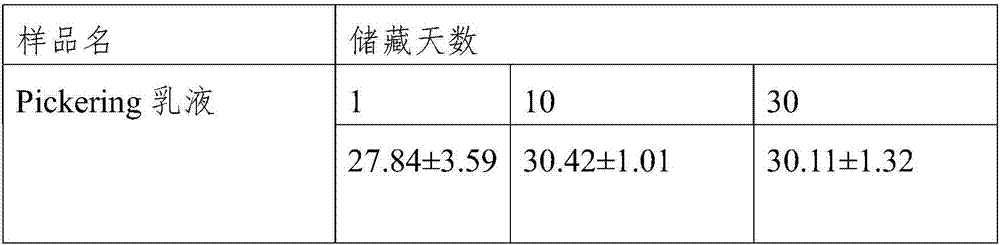

[0045] c. Add 2 times the mass of water to the gel block obtained in b, and use a high-speed disperser to shear at a high speed at 8500rpm for 35 seconds to obtain a coarse dispersion of microgel particles, and then use a high-pressure homogenizer to homogenize under high pressure at 750bar A...

Embodiment 2

[0053] The present embodiment provides a kind of method using peanut protein isolate to prepare Pickering emulsion, concrete steps are as follows:

[0054] a. Prepare 11% peanut protein isolate solution, stir for 2 hours and put it in a refrigerator at 4°C overnight to refrigerate overnight to fully hydrate the protein to obtain a peanut protein dispersion;

[0055] b. Configure a 0.05% chitosan solution, mix it with the peanut protein isolate dispersion obtained in a after stirring for 2 hours, so that the proteoglycan ratio in the final solution is 100:1, stir for 30 minutes after mixing, and use a high-speed disperser Shear the dispersion liquid at high speed for 1 minute at 11500 rpm to obtain a proteoglycan mixed dispersion liquid;

[0056] c. Adjust the pH of the dispersion to 7.2, heat it in a water bath at 83°C for 39 minutes, cool to room temperature, add (15U / g peanut protein isolate) transglutaminase, and cross-link in a water bath at 42°C 3 hours, after completion...

Embodiment 3

[0064] The present embodiment provides a kind of method using peanut protein isolate to prepare Pickering emulsion, concrete steps are as follows:

[0065] a. Prepare 27% peanut protein isolate solution, stir it for 2 hours and put it in a refrigerator at 4°C overnight to refrigerate overnight so that the protein is fully hydrated to obtain a peanut protein dispersion;

[0066] b. Configure 0.18% guar gum solution, mix it with the peanut protein isolate dispersion obtained in a after stirring for 2 hours, so that the proteoglycan ratio in the final solution is 170:1, stir for 30 minutes after mixing, and use high-speed dispersion The machine sheared the dispersion liquid at a high speed of 11500 rpm for 1 minute to obtain a proteoglycan mixed dispersion liquid;

[0067] c. Adjust the pH of the dispersion to 7.9, heat it in a 90°C water bath for 40 minutes, cool to room temperature, add (30U / g peanut protein isolate) transglutaminase, and cross-link in a 48°C water bath 4 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com