Welding gun-fixed spindle-shaped wear resisting roller surface overlaying system

A fixed and spindle-shaped welding torch technology, which is applied to welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as high labor intensity, hidden dangers of production safety, and difficulty in realizing the movement track, so as to reduce labor intensity and improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

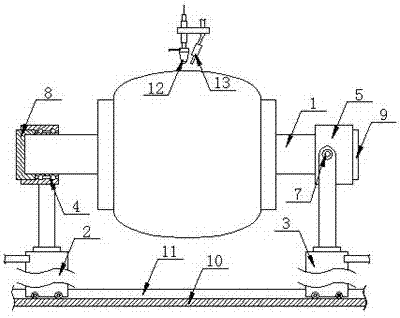

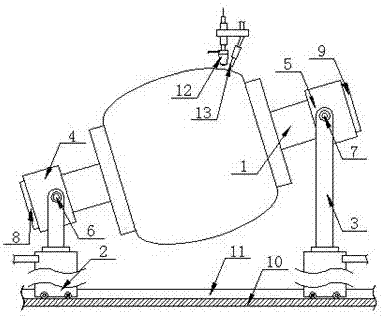

[0015] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a specific embodiment of the present invention.

[0016] Such as Figure 1 to Figure 2 As shown, a spindle-shaped wear-resistant roller surface surfacing system with a fixed welding torch includes a roller surface adjustment support column 1 for passing through the grinding roller axis and fixing the grinding roller, and the two roller surface adjustment support columns 1 The distance between the end and the grinding roller is the same; the two ends of the roller surface adjustment support column 1 are respectively provided with a support column left movement cylinder 2 and a support column right movement cylinder 3, and the support column left movement cylinder 2 and the The supporting column right moving hydraulic cylinder 3 is arranged vertically upwards with the piston rod, and the cylinder barrels of the supporting column left moving hydraulic cylinder 2 and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com