Method for processing glass camera lens and device therefor

A processing method and camera technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems of unsatisfactory product performance, low processing profit, high processing time cost and labor cost, and achieve low cost , easy to obtain, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

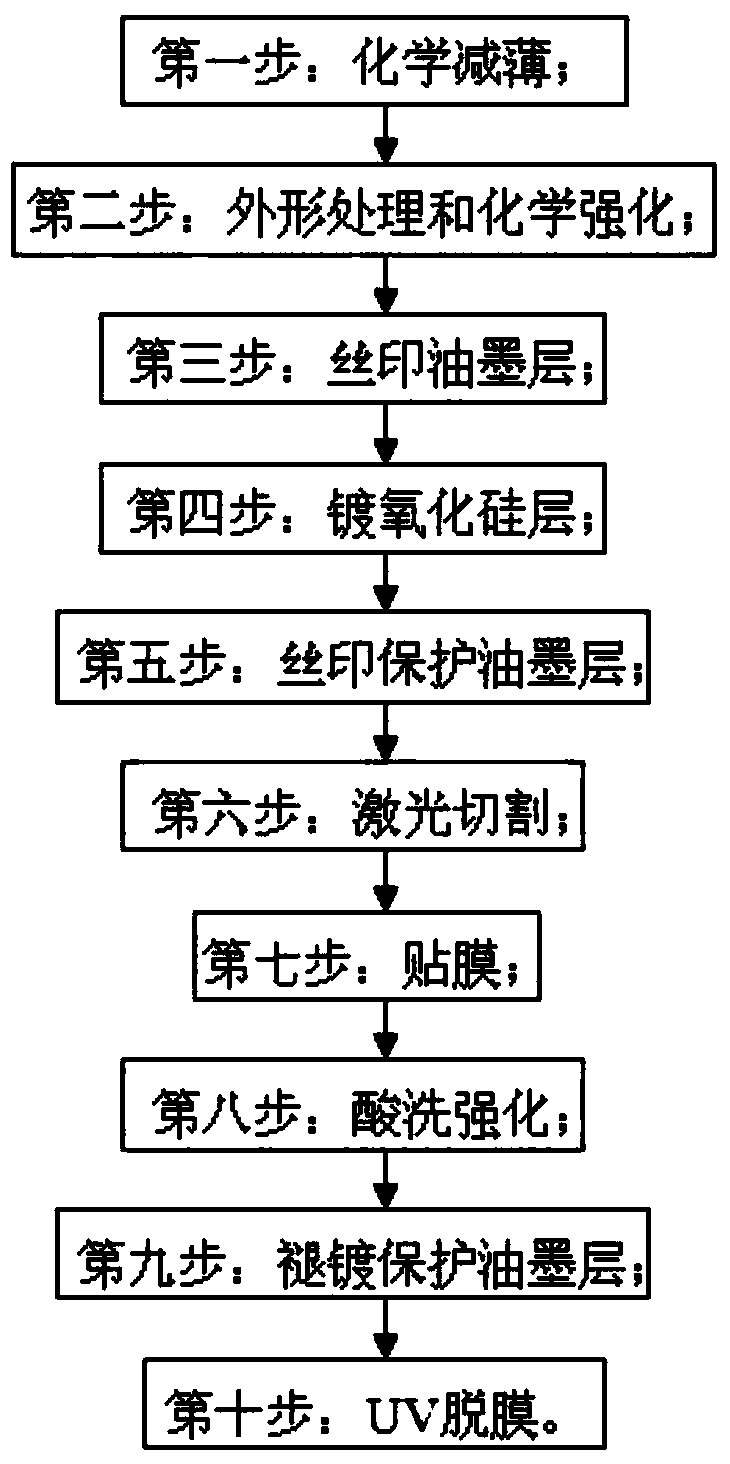

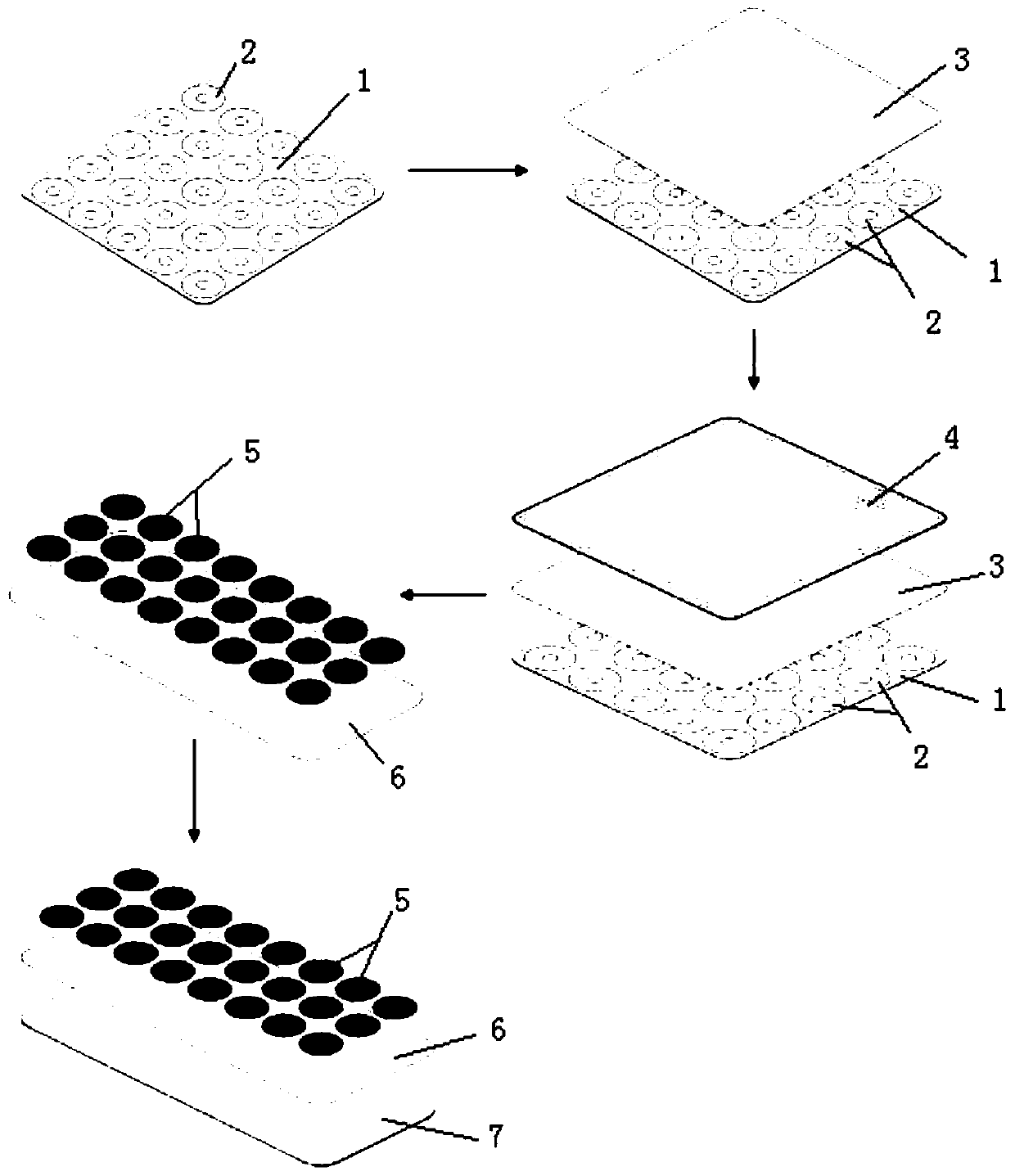

[0057] see figure 1 as well as figure 2 , a method for processing a glass camera lens, the details are as follows:

[0058] Prepare the equipment first, specifically: prepare a treatment tank for chemical thinning and pickling strengthening, the treatment tank is a U-shaped tank resistant to the compound acid; prepare a CNC machine tool for processing the workpiece into the required shape; prepare a glass chemical strengthening furnace for chemical strengthening of the workpiece after shape treatment; prepare a fully automatic CCD positioning screen printing machine for silk screen printing ink layer and silk screen layer protection on the surface of the workpiece Ink layer; prepare a vacuum sputtering coating machine for electroplating a layer of silicon oxide on the ink layer of the workpiece; prepare a picosecond laser cutting machine for cutting the workpiece into multiple glass cameras by laser cutting machine Lens samples; prepare a film laminating machine for affixin...

Embodiment 2- Embodiment 6

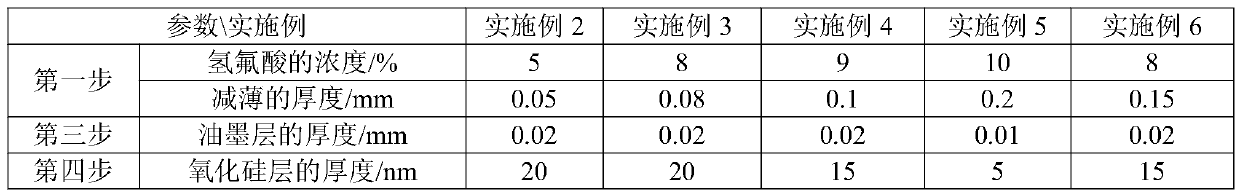

[0073] Embodiment 2-Embodiment 6 differs from Embodiment 1 only in the parameters in Table 1, see Table 1 for details.

[0074] The part process parameter statistical table of table 1 embodiment 2-embodiment 6

[0075]

[0076]

[0077] Example 2-Example 6 were subjected to the same test as Example 1, and the results are shown in Table 2.

[0078] The product performance statistical table of table 2 embodiment 1-embodiment 6

[0079]

[0080] It can be seen from Table 2 that the glass camera lens obtained by adopting the technical solution of the present invention can greatly reduce manpower, material resources, and equipment investment, and at the same time can greatly improve the product process yield and improve production and processing efficiency, and can achieve profitability for the enterprise the goal of.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com