Rubber composition applied to fireproof series of TBR tire treads

A radial tire and rubber composition technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of lack of flame retardant and fireproof function, reduced tire performance, and impact on service life, and achieve excellent fire safety. performance, improving flame retardant and fire resistance, and the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

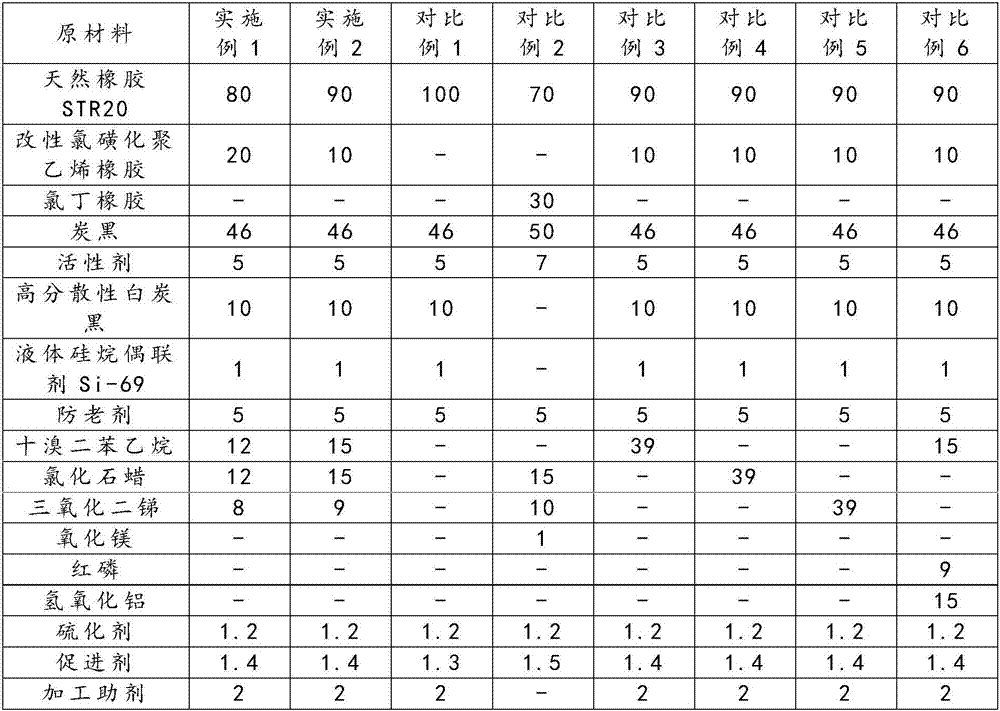

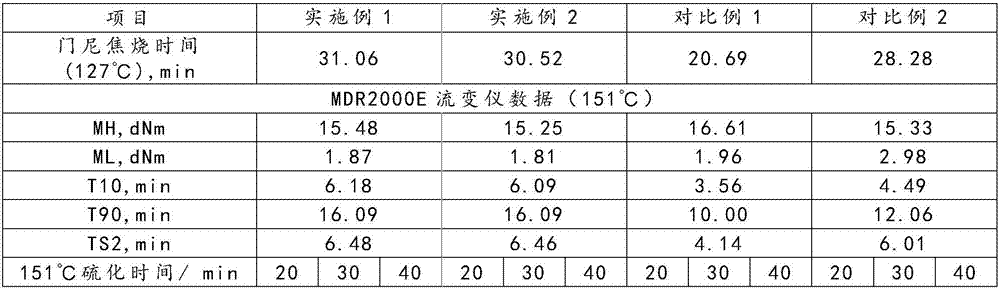

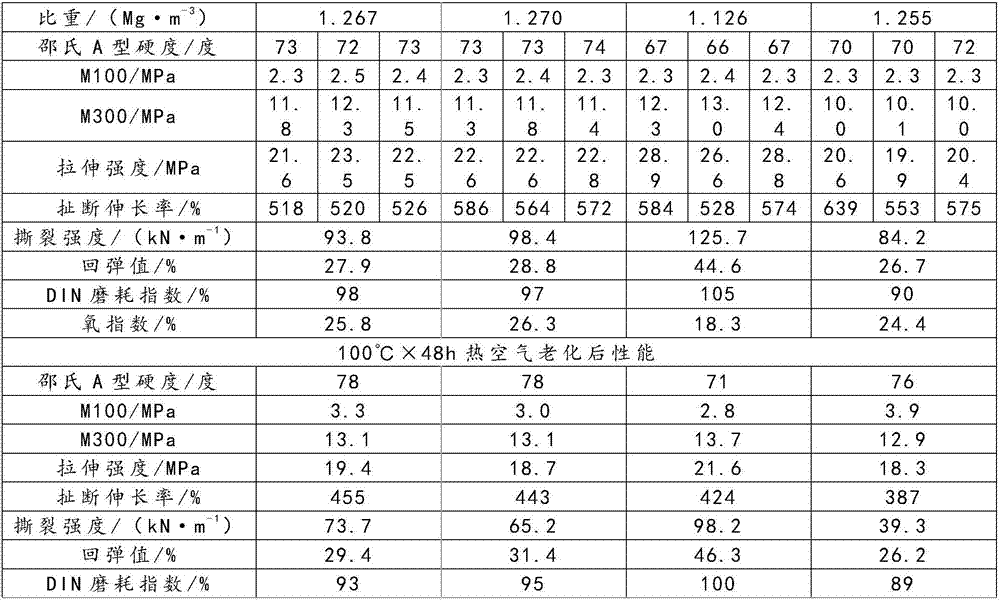

[0046] Each component is measured in parts by mass, see Table 1.

[0047] The mixing method of this rubber composition is as follows:

[0048] After masticating the raw rubber with a closed rubber mixer for 0.5-1min, add some carbon black, high-dispersion silica and all components except the vulcanization system and protection system, and mix for 2-3min at 150-160°C Internal discharge, complete the preparation of a masterbatch;

[0049] After the film is parked for 8 hours, add the primary masterbatch, remaining carbon black and components of the anti-aging system to the closed rubber mixer, and mix for 2-3 minutes at a temperature of 145-155°C to complete the secondary masterbatch. preparation;

[0050] After the film is parked for 8 hours, add the second-stage masterbatch and all the components of the vulcanization system into the closed rubber mixer, and mix for 2-3 minutes at a temperature of 95-105°C to discharge the rubber to complete the preparation of the final rubbe...

Embodiment 2

[0053] Each component is measured in parts by mass, see Table 1, and the mixing method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com